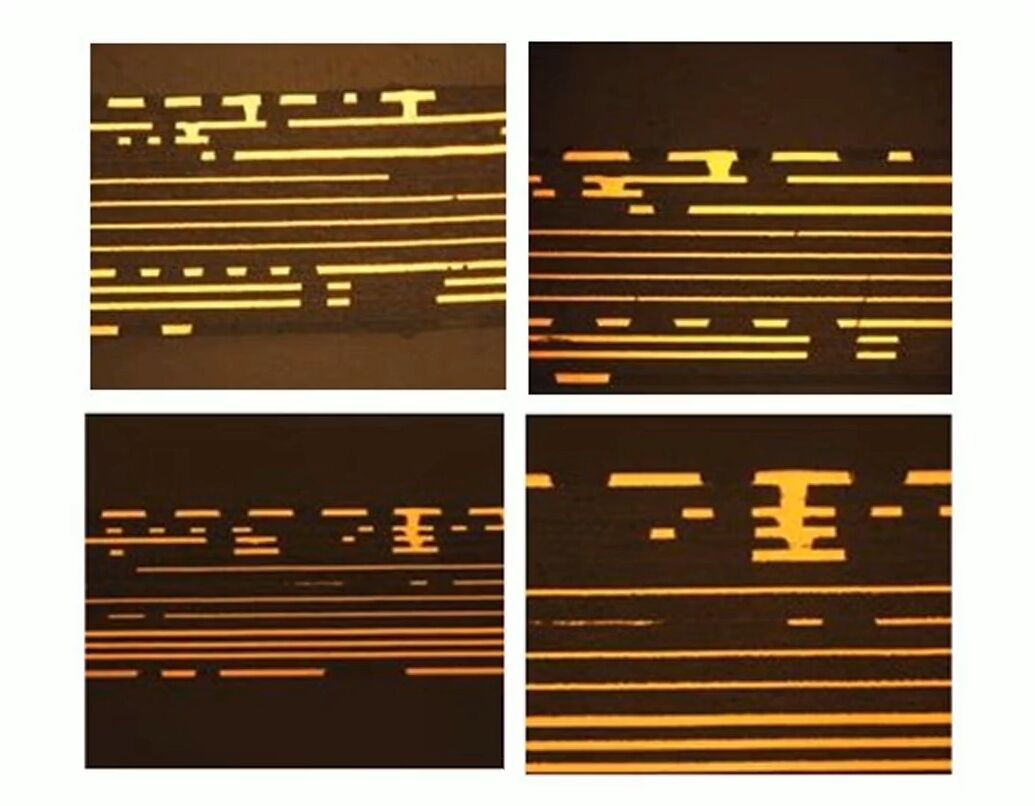

circuit board fr4

FR4 circuit boards represent the industry standard in electronic manufacturing, combining superior performance with cost-effectiveness. This glass-reinforced epoxy laminate material consists of multiple layers of fiberglass cloth bonded with epoxy resin, creating a robust and versatile substrate for electronic components. The designation FR4 stands for Flame Retardant Class 4, indicating its excellent fire-resistant properties. These circuit boards feature outstanding electrical insulation properties, with a typical dielectric constant ranging from 4.2 to 4.8, making them ideal for high-frequency applications. FR4 boards maintain their mechanical and electrical properties across a wide temperature range, typically from -50°C to +140°C, ensuring reliable performance in various operating conditions. The material's dimensional stability and low moisture absorption characteristics make it particularly suitable for multilayer PCB applications. Additionally, FR4 circuit boards offer excellent chemical resistance and mechanical strength, contributing to their longevity and reliability in electronic devices.