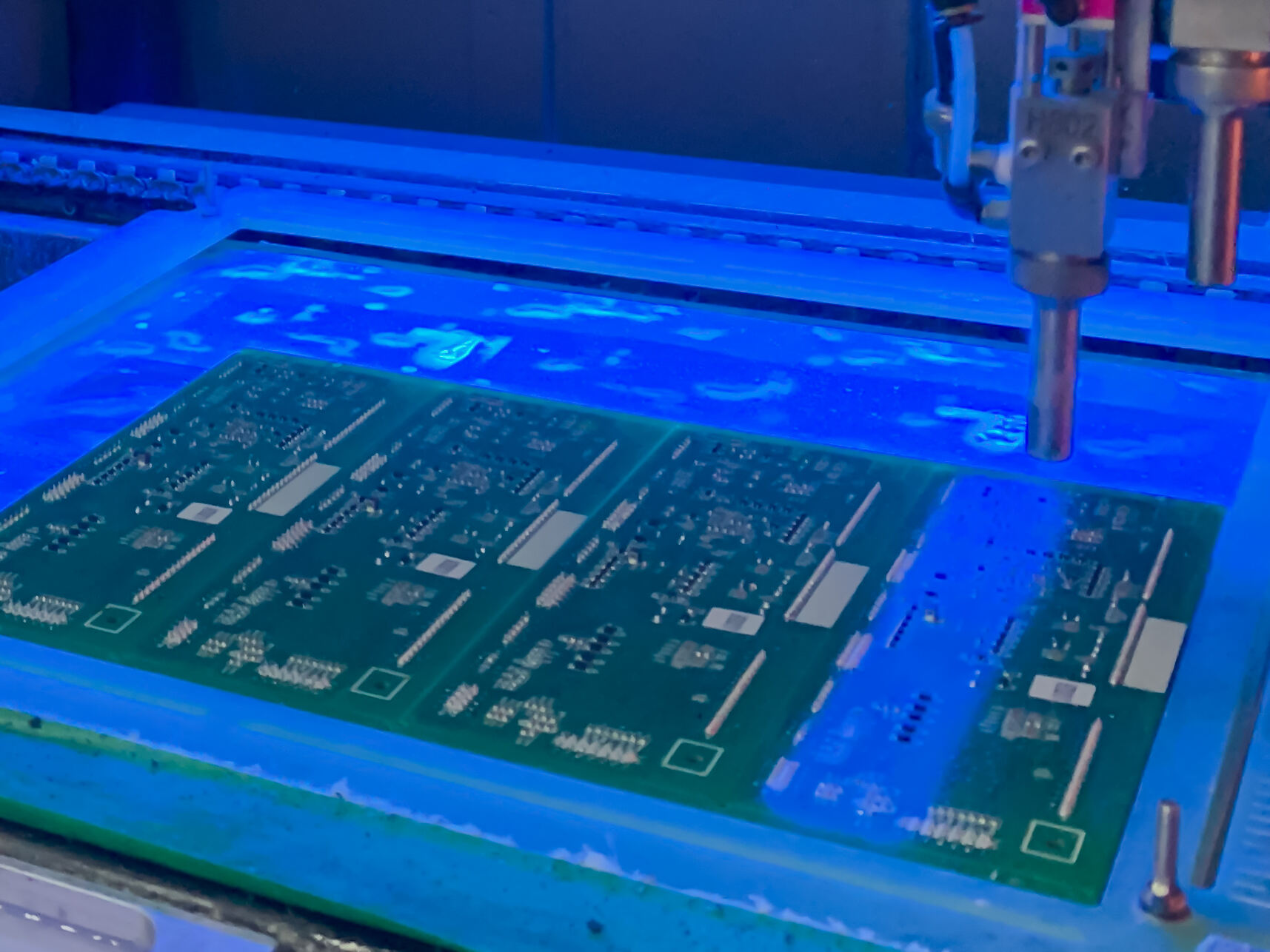

pcb fr 4

PCB FR4 (Flame Retardant 4) is a composite material widely used in the electronics industry as the primary substrate for printed circuit boards. This versatile material consists of woven fiberglass cloth impregnated with epoxy resin, creating a robust and reliable foundation for electronic components. The FR4 designation indicates its flame-retardant properties, meeting UL94 V-0 standards for fire safety. The material offers exceptional electrical insulation properties with a dielectric constant typically ranging from 4.0 to 4.5, making it ideal for high-frequency applications. PCB FR4 maintains dimensional stability across varying temperatures, with a glass transition temperature (Tg) usually between 130°C and 140°C for standard grades and up to 170°C for high-performance variants. The material's physical properties include excellent mechanical strength, low water absorption, and high chemical resistance, ensuring longevity in diverse operating environments. In modern electronics manufacturing, PCB FR4 serves as the backbone for everything from consumer electronics to industrial control systems, telecommunications equipment, and automotive electronics.