fr4 tg

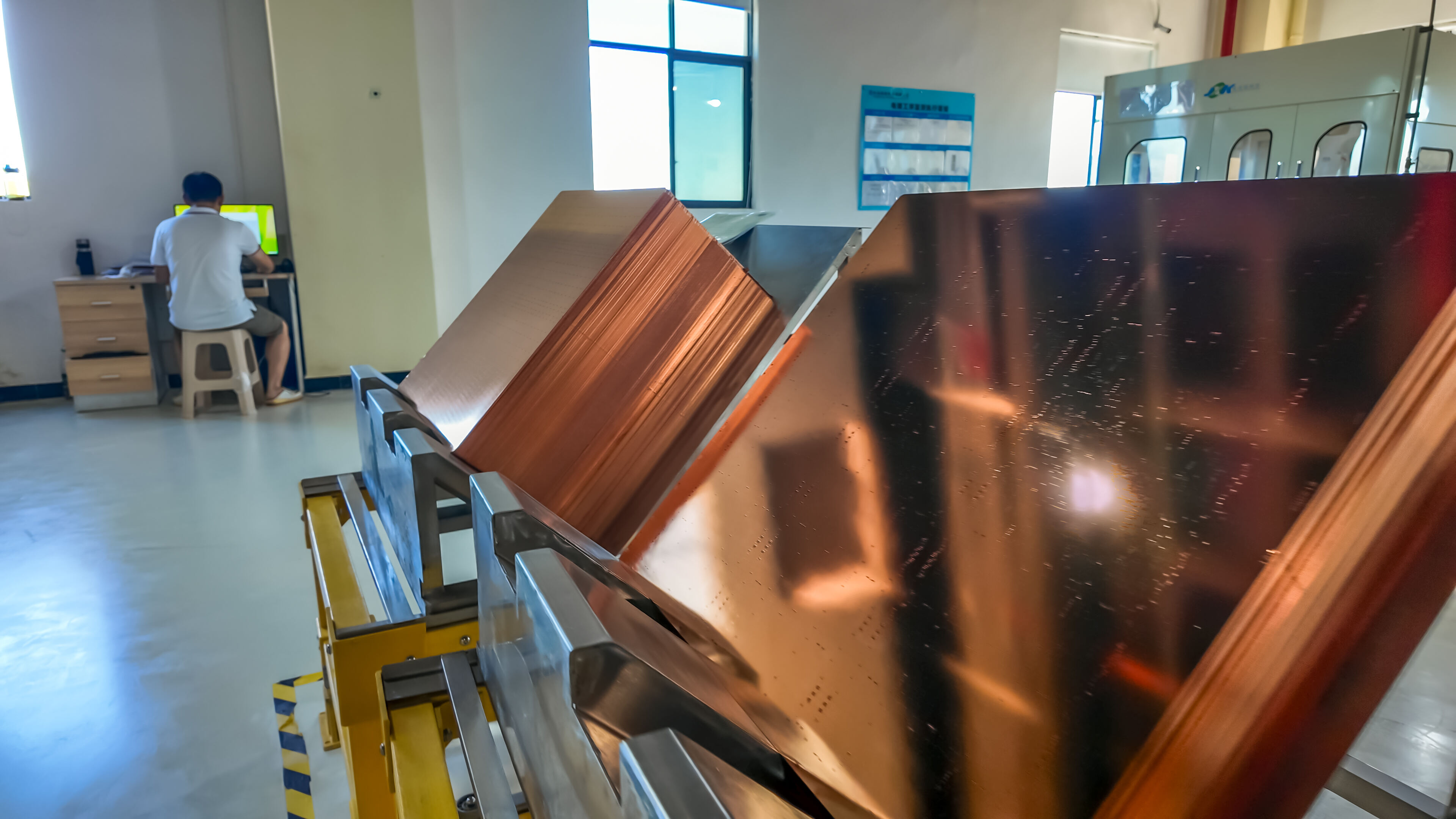

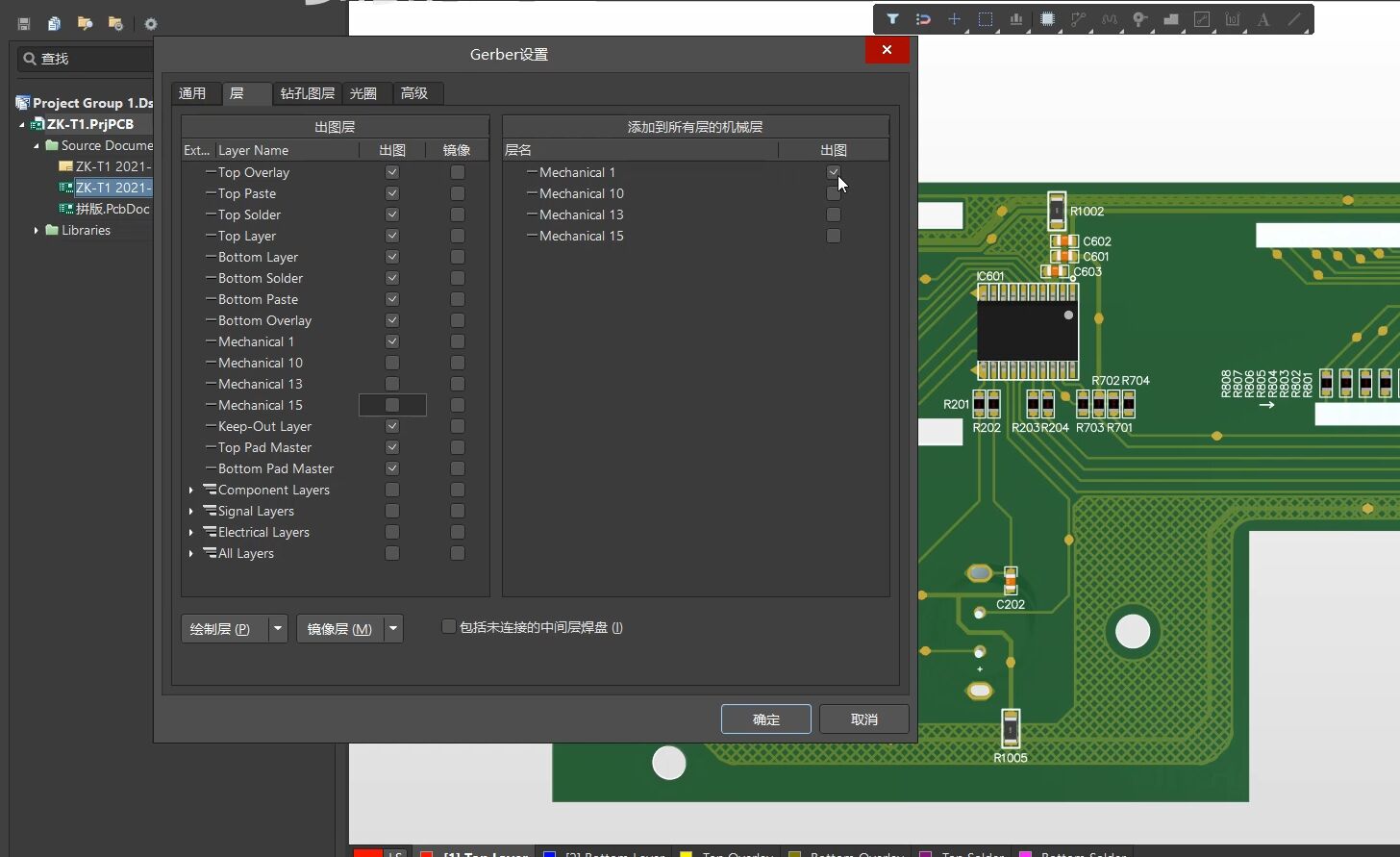

FR4 TG (Flame Retardant 4 with Glass Transition) represents a significant advancement in printed circuit board (PCB) materials. This composite material consists of woven fiberglass cloth impregnated with epoxy resin, offering exceptional thermal and electrical properties. The glass transition temperature of FR4 TG typically ranges from 130°C to 180°C, making it highly suitable for demanding electronic applications. The material's flame retardant properties meet UL94 V-0 standards, ensuring safety in electronic devices. FR4 TG demonstrates remarkable mechanical strength, excellent electrical insulation properties, and consistent dimensional stability across varying temperatures. These characteristics make it the preferred choice for multilayer PCBs in consumer electronics, telecommunications equipment, and industrial control systems. The material's low water absorption rate and superior chemical resistance contribute to its reliability in diverse operating environments. FR4 TG's versatility allows for various copper foil thicknesses and layer configurations, enabling manufacturers to meet specific design requirements while maintaining cost effectiveness.