ptfe pcb

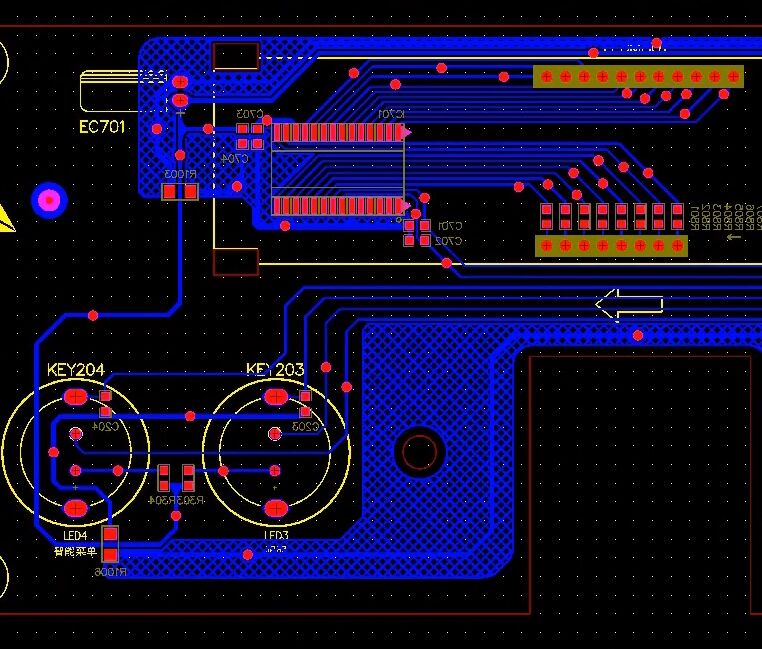

PTFE PCB (Polytetrafluoroethylene Printed Circuit Board) represents a significant advancement in high-frequency circuit technology. These specialized circuit boards utilize PTFE as the primary dielectric material, offering exceptional electrical properties and thermal stability. The unique composition of PTFE PCBs makes them ideal for applications requiring minimal signal loss and consistent performance across a wide frequency range. These boards feature extremely low dielectric constants and dissipation factors, enabling them to maintain signal integrity even at frequencies exceeding 10 GHz. The manufacturing process involves carefully bonding PTFE material with copper foil under precise temperature and pressure conditions, resulting in a highly reliable substrate. PTFE PCBs excel in applications where traditional FR4 boards fall short, particularly in RF and microwave circuits. Their inherent resistance to moisture and chemicals, combined with excellent thermal stability, makes them suitable for harsh environment deployments. The boards can withstand temperatures from -55°C to +260°C without significant degradation in electrical properties, ensuring consistent performance across extreme conditions. In modern telecommunications, aerospace, and military applications, PTFE PCBs serve as critical components in radar systems, satellite communications, and high-speed digital circuits.