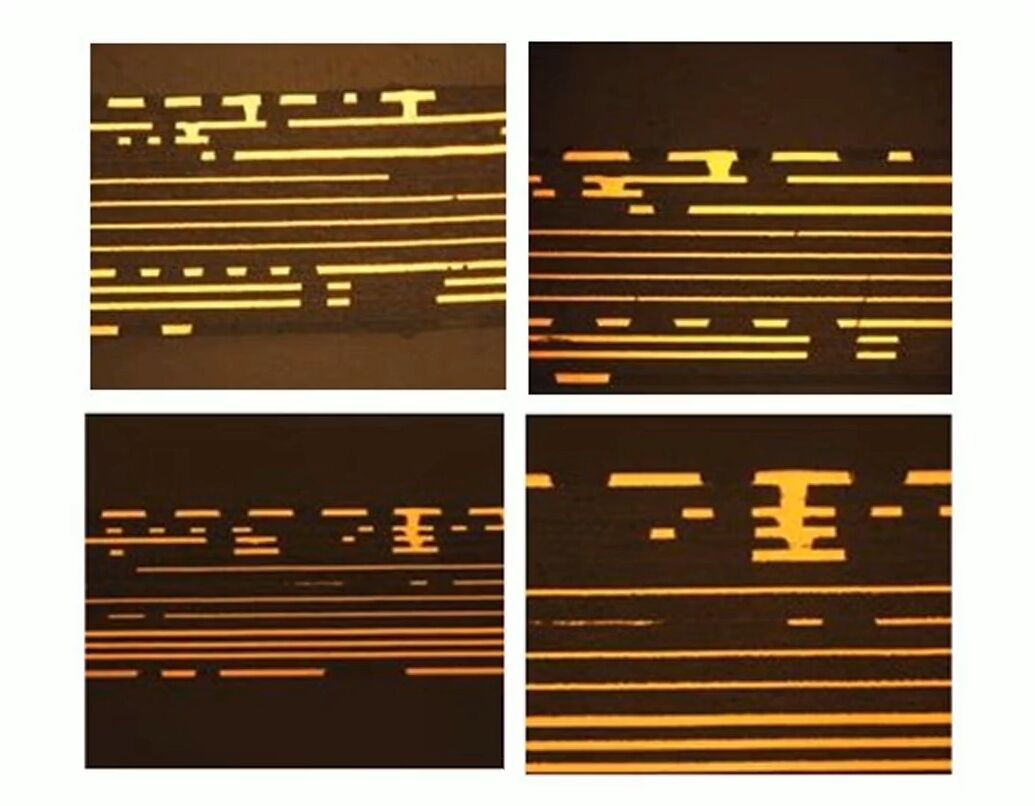

circuit board material fr4

FR4, or Flame Retardant 4, is a composite material widely used in the manufacture of printed circuit boards (PCBs). This versatile material consists of woven fiberglass cloth impregnated with an epoxy resin that becomes rigid when cured. The designation FR4 indicates its compliance with the UL94V-0 standard for flame retardancy. The material exhibits exceptional electrical insulation properties, with a dielectric constant typically ranging from 4.2 to 4.8, making it ideal for high-frequency applications. FR4's mechanical strength is remarkable, offering excellent dimensional stability across varying temperatures and humidity levels. The material maintains its structural integrity in temperatures ranging from -50°C to +140°C, making it suitable for diverse operating environments. Its unique composition provides a perfect balance between electrical performance, mechanical durability, and cost-effectiveness. FR4 serves as the foundation for most modern electronic devices, from consumer electronics to industrial control systems. The material's reliability in multilayer PCB construction, combined with its resistance to moisture absorption and chemical exposure, has established it as the industry standard. Its widespread adoption is further supported by its compatibility with various surface finishing techniques and its ability to withstand modern manufacturing processes, including automated assembly and wave soldering.