pcb laminate material

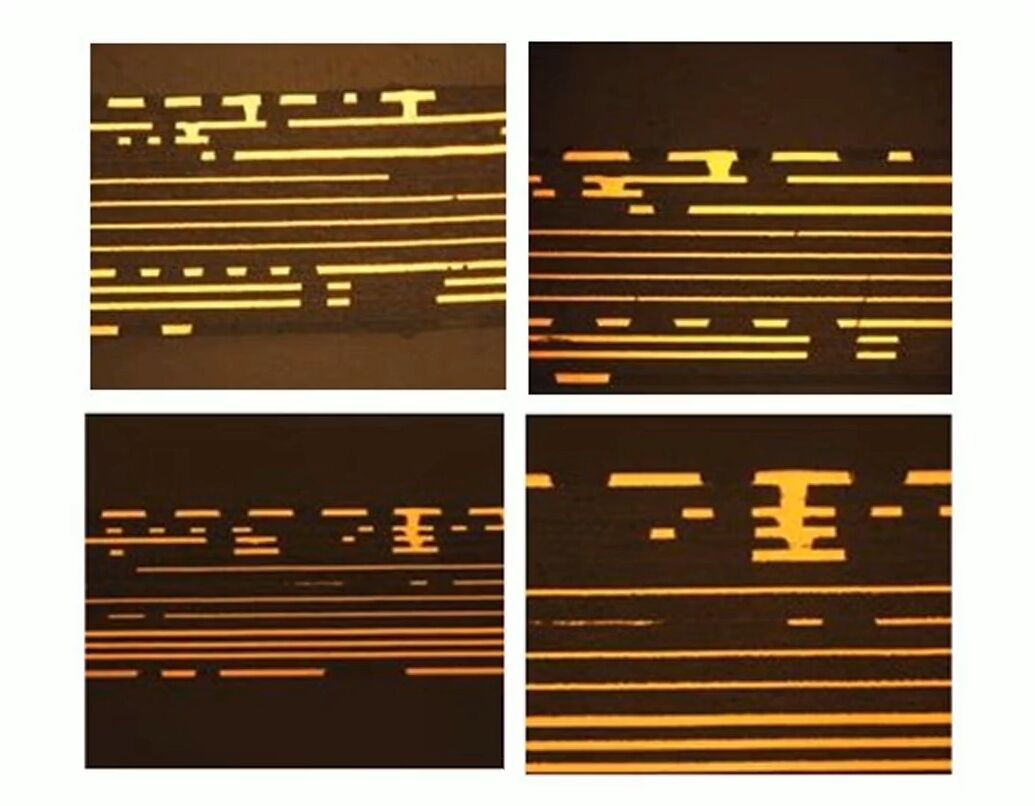

PCB laminate material serves as the fundamental building block in printed circuit board manufacturing, providing the essential foundation for electronic components and circuitry. This versatile material consists of multiple layers of substrates, typically made from glass-reinforced epoxy resin, which are bonded together under precise temperature and pressure conditions. The material's composition is carefully engineered to deliver optimal electrical insulation, mechanical strength, and thermal stability. Modern PCB laminates feature advanced properties including controlled dielectric constants, low signal loss characteristics, and enhanced thermal conductivity. These materials are available in various grades and specifications to meet different application requirements, from standard FR-4 for common electronic devices to high-performance materials for specialized applications in telecommunications, aerospace, and military equipment. The laminate's structure includes copper foil layers that can be etched to create circuit patterns, while the core material provides the necessary rigidity and electrical isolation. Advanced PCB laminates also incorporate flame-retardant properties and maintain dimensional stability across varying environmental conditions, ensuring reliable performance in diverse operating environments.