fr4 material

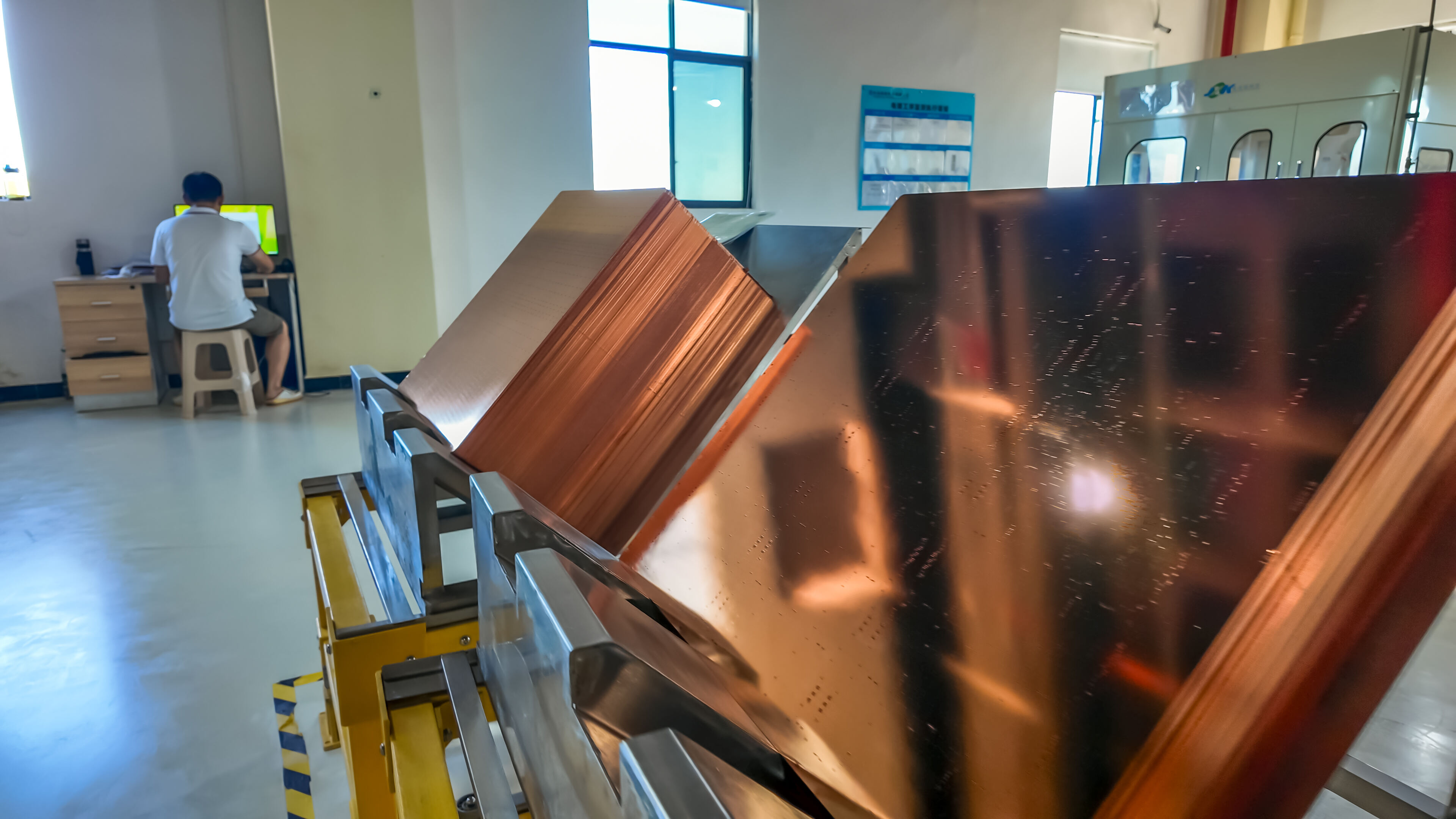

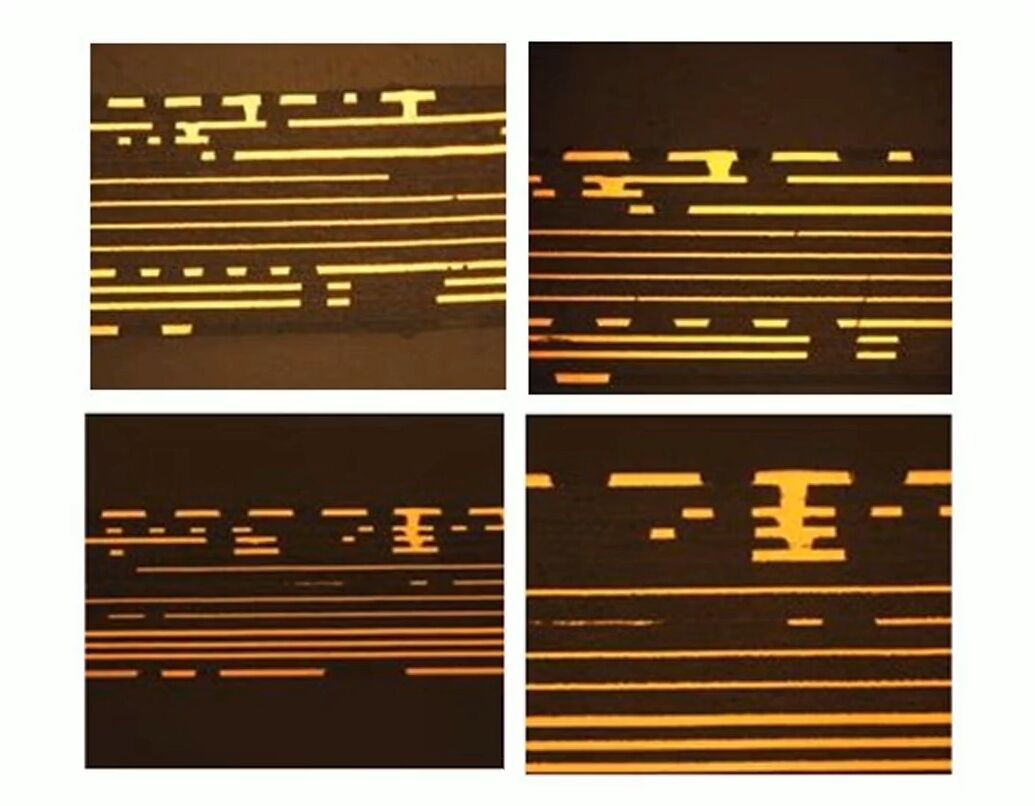

FR4 material, also known as Flame Retardant 4, is a versatile composite material widely used in the electronics industry, particularly in printed circuit board (PCB) manufacturing. This glass-reinforced epoxy laminate material consists of multiple layers of woven fiberglass cloth impregnated with epoxy resin, creating a robust and reliable substrate. FR4 offers exceptional electrical insulation properties, maintaining stable performance across varying temperatures and environmental conditions. The material demonstrates remarkable mechanical strength, with a high tensile strength and resistance to bending and warping. Its flame-retardant properties meet UL94 V-0 standards, making it ideal for applications where fire safety is crucial. FR4's low moisture absorption rate and excellent dimensional stability ensure consistent performance in diverse operating conditions. The material's thermal resistance allows it to withstand soldering temperatures and maintain its structural integrity during manufacturing processes. In the electronics industry, FR4 serves as the foundation for countless devices, from consumer electronics to industrial equipment, telecommunications infrastructure, and automotive systems.