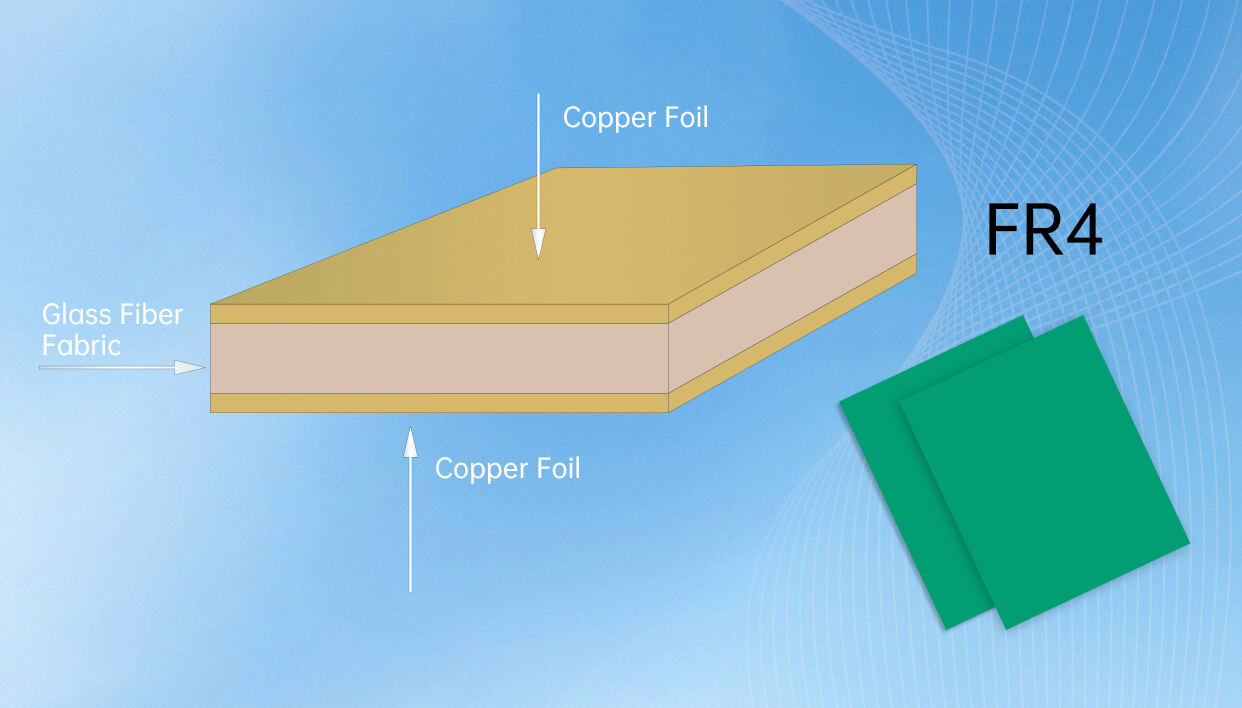

fr4 pcb board

FR4 PCB boards represent the industry standard in printed circuit board manufacturing, consisting of a fiberglass-reinforced epoxy laminate material that serves as the foundation for electronic components. These boards feature multiple layers of copper-clad material, with FR4 standing for Flame Retardant Class 4, indicating its superior fire-resistant properties. The board's construction involves weaving glass fibers into a cloth that is then combined with epoxy resin to create a robust and reliable substrate. FR4 PCB boards typically maintain excellent electrical insulation properties while offering remarkable mechanical strength. They demonstrate consistent performance across varying temperatures, making them suitable for diverse applications ranging from consumer electronics to industrial equipment. The material's low water absorption rate, combined with its high thermal resistance, ensures long-term stability and reliability in electronic devices. FR4 PCB boards can be manufactured in various thicknesses and layer counts, accommodating complex circuit designs and high-density component placement. Their widespread adoption in the electronics industry is attributed to their balanced combination of electrical, mechanical, and thermal properties, along with their cost-effectiveness and manufacturing versatility.