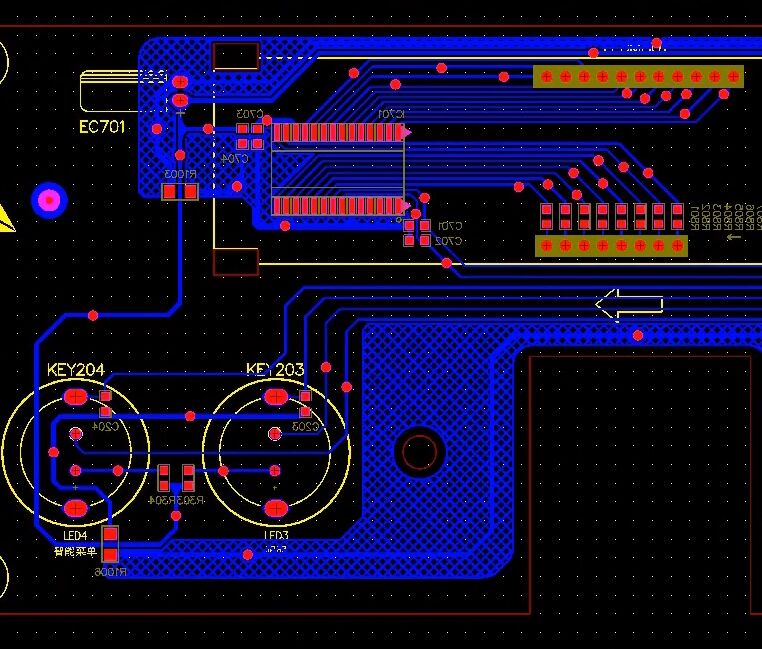

semiflex pcb

A semiflex PCB (Printed Circuit Board) represents a revolutionary hybrid solution in electronics manufacturing, combining the best attributes of both rigid and flexible PCBs. These innovative boards feature specialized areas that can bend or flex while maintaining rigid sections for component mounting and structural stability. The design typically incorporates a unique layered construction, using materials that allow controlled flexibility in predetermined areas while ensuring rigidity where needed. The semiflex PCB achieves this versatility through strategic placement of different material layers and careful consideration of bend radius requirements. These boards excel in applications where limited flexibility is required, such as connecting two rigid boards or accommodating space constraints in electronic devices. The technology enables designers to eliminate the need for connectors in many applications, reducing potential failure points and improving overall system reliability. Semiflex PCBs are particularly valuable in modern electronics where space is at a premium, offering a compact solution that can be folded or bent to fit into tight spaces while maintaining excellent electrical performance. The manufacturing process involves precise control of material properties and thickness, ensuring consistent performance across both rigid and flexible sections. This technology has found widespread adoption in automotive electronics, medical devices, aerospace applications, and consumer electronics, where reliability and space optimization are crucial factors.