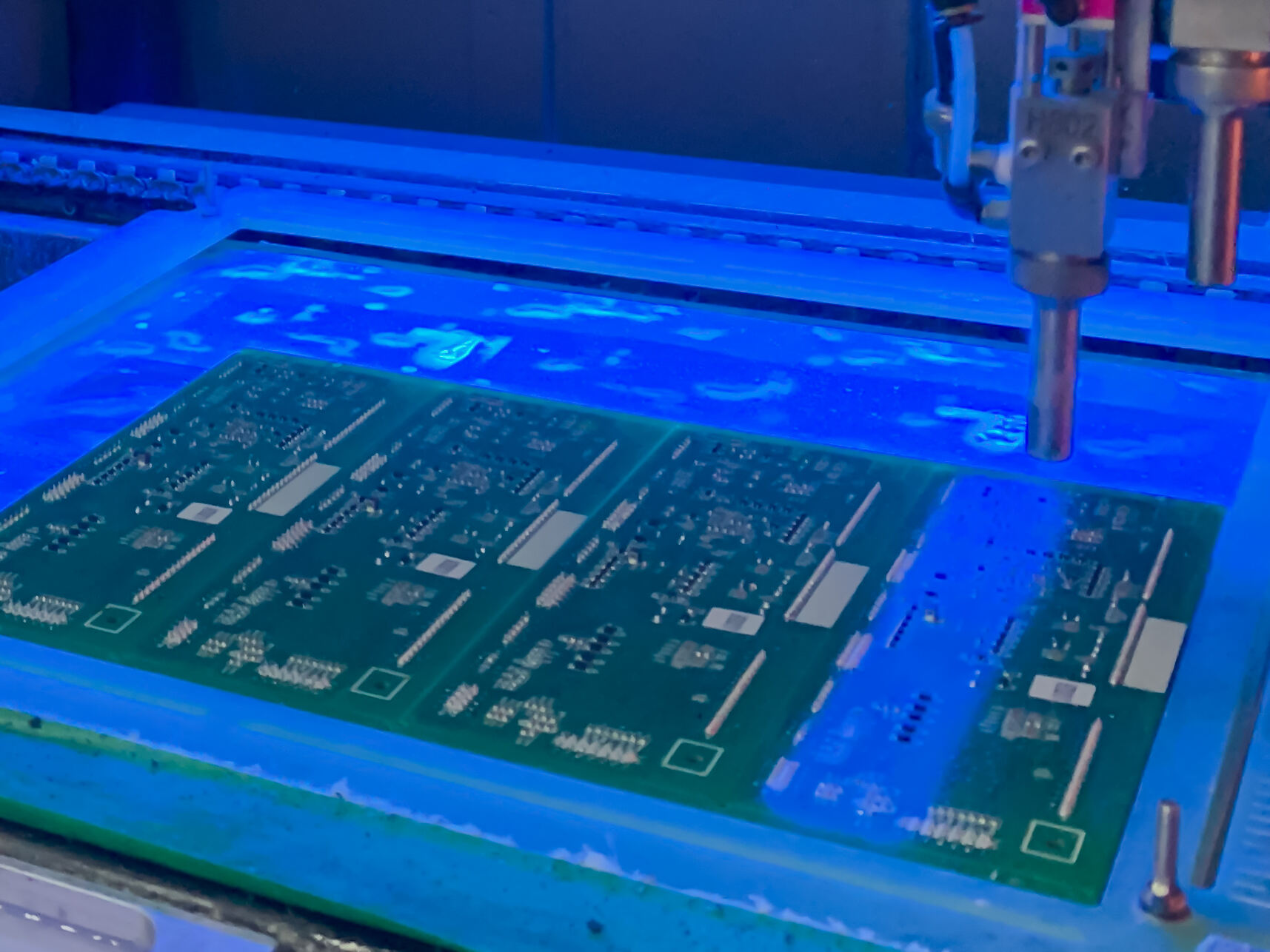

silkscreen

A silkscreen is a versatile printing method that has revolutionized the commercial printing industry. This technique involves pushing ink through a mesh stencil onto a substrate, creating precise and durable prints on various materials. The process begins with a fine mesh screen, typically made from synthetic materials or silk, stretched tightly over a frame. The mesh is then coated with a light-sensitive emulsion and exposed to UV light through a film positive, creating a stencil. Areas exposed to light harden, while unexposed areas wash away, forming the printing areas. The ink is then forced through these open areas using a squeegee, transferring the design onto the printing surface. Modern silkscreen technology has evolved to include automated systems, precise registration controls, and advanced ink formulations, making it suitable for both small-scale artistic projects and large industrial applications. The technique excels in producing vibrant colors, thick ink deposits, and consistent results across various materials including textiles, paper, plastic, metal, and glass. This versatility, combined with its cost-effectiveness for bulk production, has made silkscreen printing an essential tool in industries ranging from textile manufacturing to electronics production.