pcb manufacturing and assembly

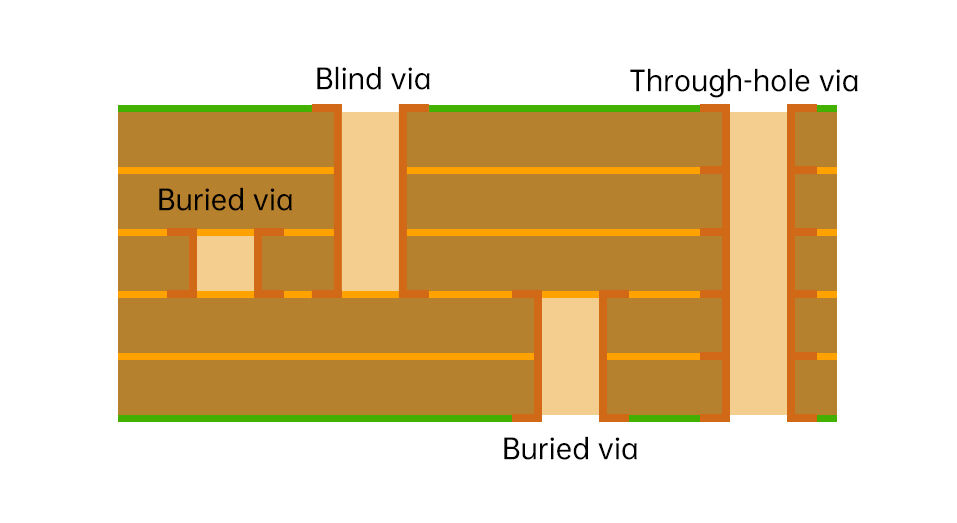

PCB manufacturing and assembly represents a crucial process in electronics production, encompassing the creation and population of printed circuit boards that serve as the foundation for modern electronic devices. The process begins with design and engineering, where circuit layouts are meticulously planned using advanced CAD software. The manufacturing phase involves multiple sophisticated steps, including photolithography, etching, and layering of conductive materials to create the circuit pathways. Advanced manufacturing facilities employ state-of-the-art equipment for precise drilling, plating, and testing. The assembly phase involves both automated and manual processes, utilizing surface mount technology (SMT) and through-hole mounting techniques to place and secure components. Quality control measures are implemented throughout, including automated optical inspection (AOI) and functional testing to ensure reliability. This comprehensive process supports applications ranging from consumer electronics to aerospace technology, medical devices, and industrial equipment. Modern PCB manufacturing and assembly facilities offer capabilities for both prototype and high-volume production, with options for various board materials, thicknesses, and complexities, including multi-layer boards and flexible circuits.