pcb packaging

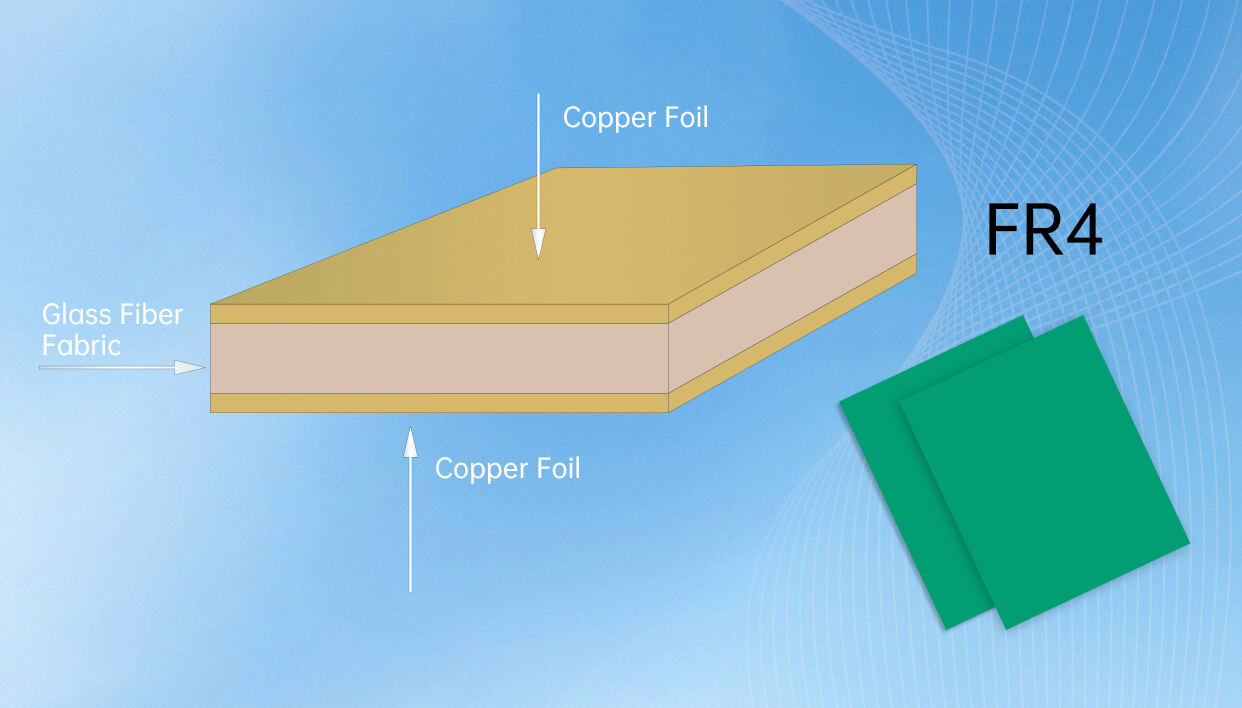

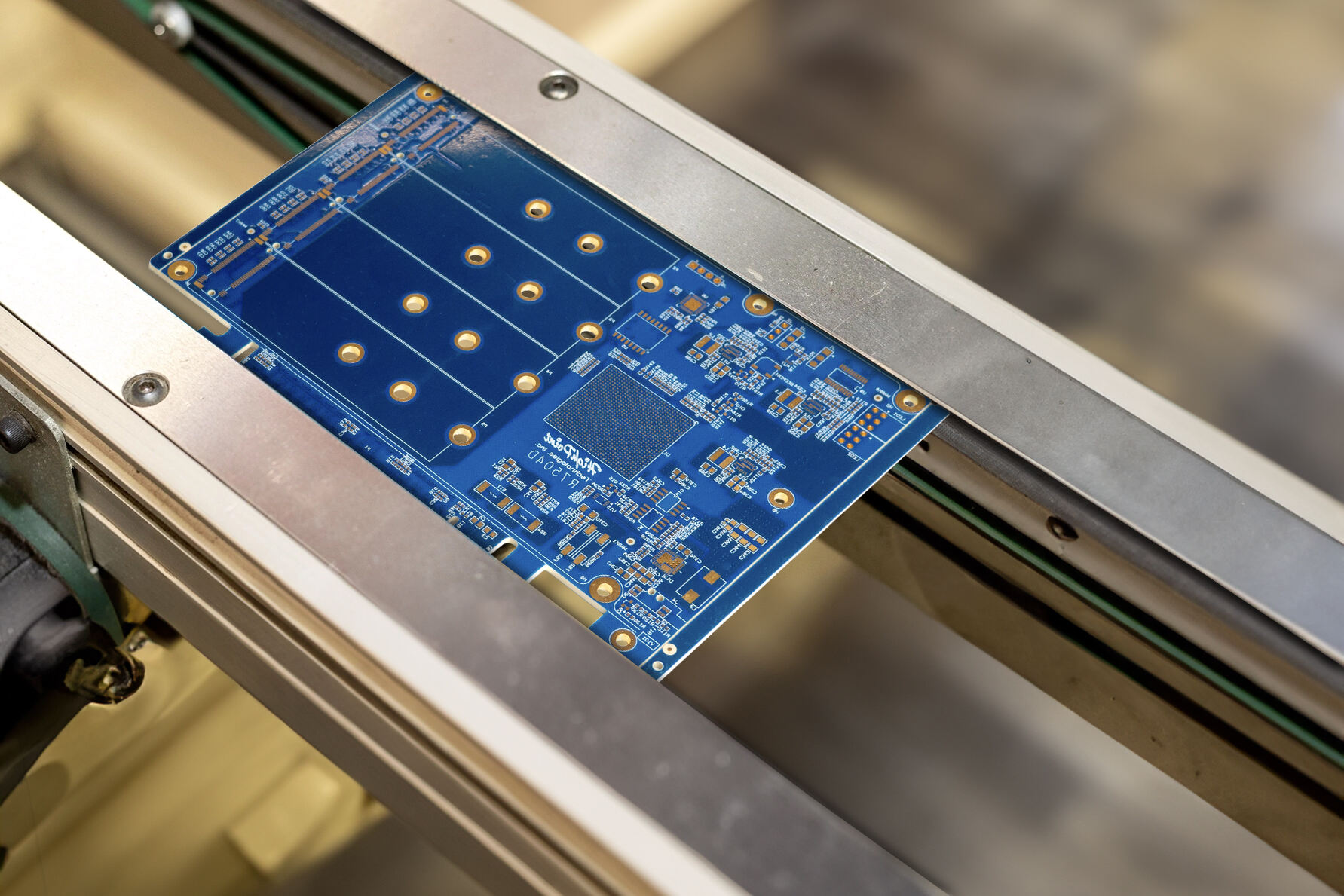

PCB packaging represents a critical aspect of electronic component protection and integration, serving as the foundation for reliable electronic device performance. This specialized packaging solution encompasses various materials and techniques designed to safeguard printed circuit boards throughout their operational lifetime. The primary function of PCB packaging is to protect sensitive electronic components from environmental factors such as moisture, dust, and electromagnetic interference while ensuring proper thermal management and mechanical stability. Modern PCB packaging technologies incorporate advanced materials such as moisture-barrier films, thermal interface materials, and electromagnetic shielding compounds. These packaging solutions are engineered to meet diverse industry requirements, from consumer electronics to aerospace applications. The packaging process includes multiple layers of protection, starting with conformal coatings, followed by structural supports, and finally, external enclosures. This comprehensive approach ensures optimal performance and longevity of the electronic components. PCB packaging also facilitates easier handling, storage, and transportation of circuit boards while maintaining their integrity and functionality. The technology continues to evolve, with newer solutions offering enhanced protection features, improved thermal management capabilities, and better integration options for various electronic applications.