pcb manufacturing service

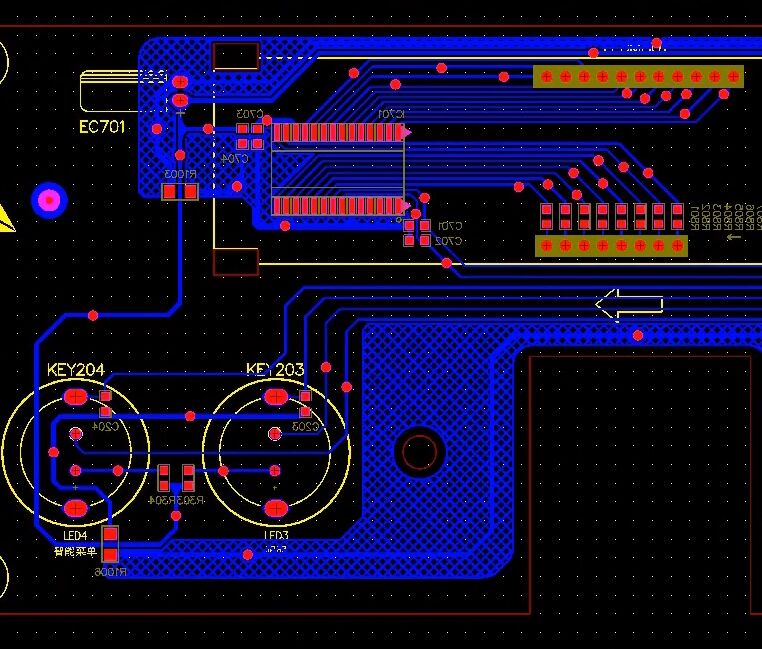

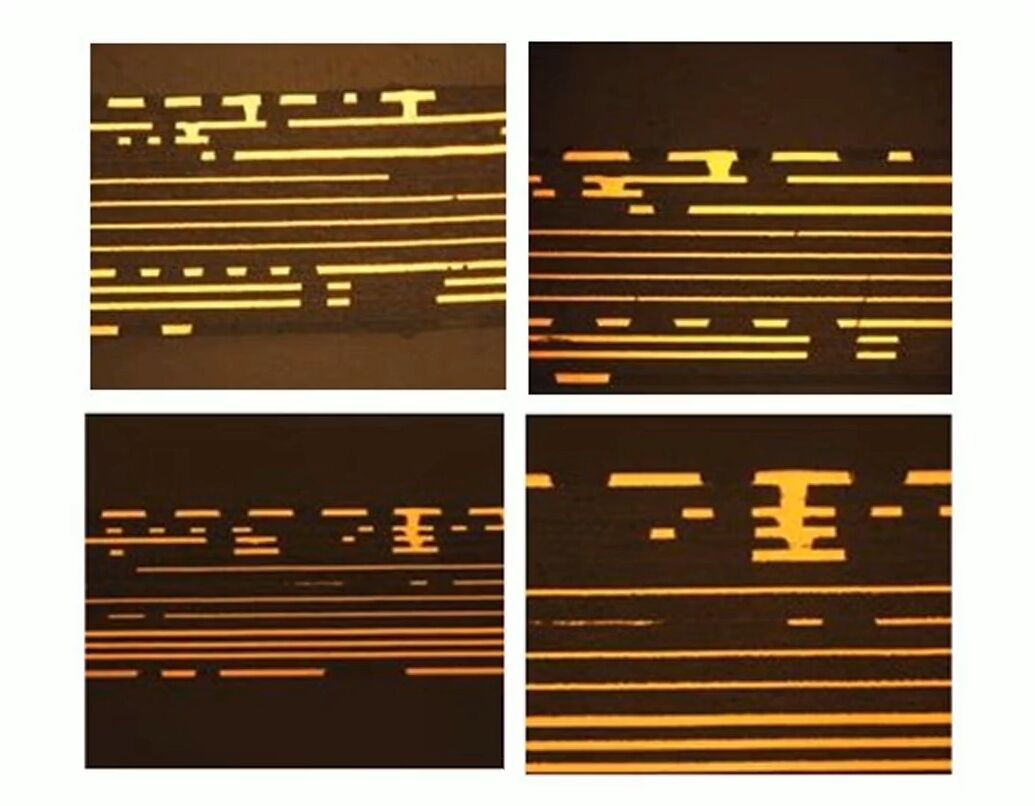

PCB manufacturing service represents a comprehensive solution for producing high-quality printed circuit boards essential in modern electronics. This service encompasses the entire production cycle, from initial design verification to final quality inspection. Using state-of-the-art manufacturing equipment and advanced process control systems, these services ensure precise layer alignment, accurate copper thickness, and consistent board quality. The manufacturing process includes professional photoresist application, precise etching procedures, and automated optical inspection (AOI) systems that guarantee board integrity. Modern PCB manufacturing facilities maintain strict cleanliness standards in their production environments and employ advanced surface finish technologies such as HASL, ENIG, and immersion gold. These services accommodate various board specifications, including multi-layer designs, flexible circuits, and high-density interconnect (HDI) boards. They also offer specialized options like impedance control, blind and buried vias, and advanced material selections for specific applications. The service typically includes comprehensive testing procedures, ensuring electrical connectivity, impedance matching, and overall board functionality before shipment.