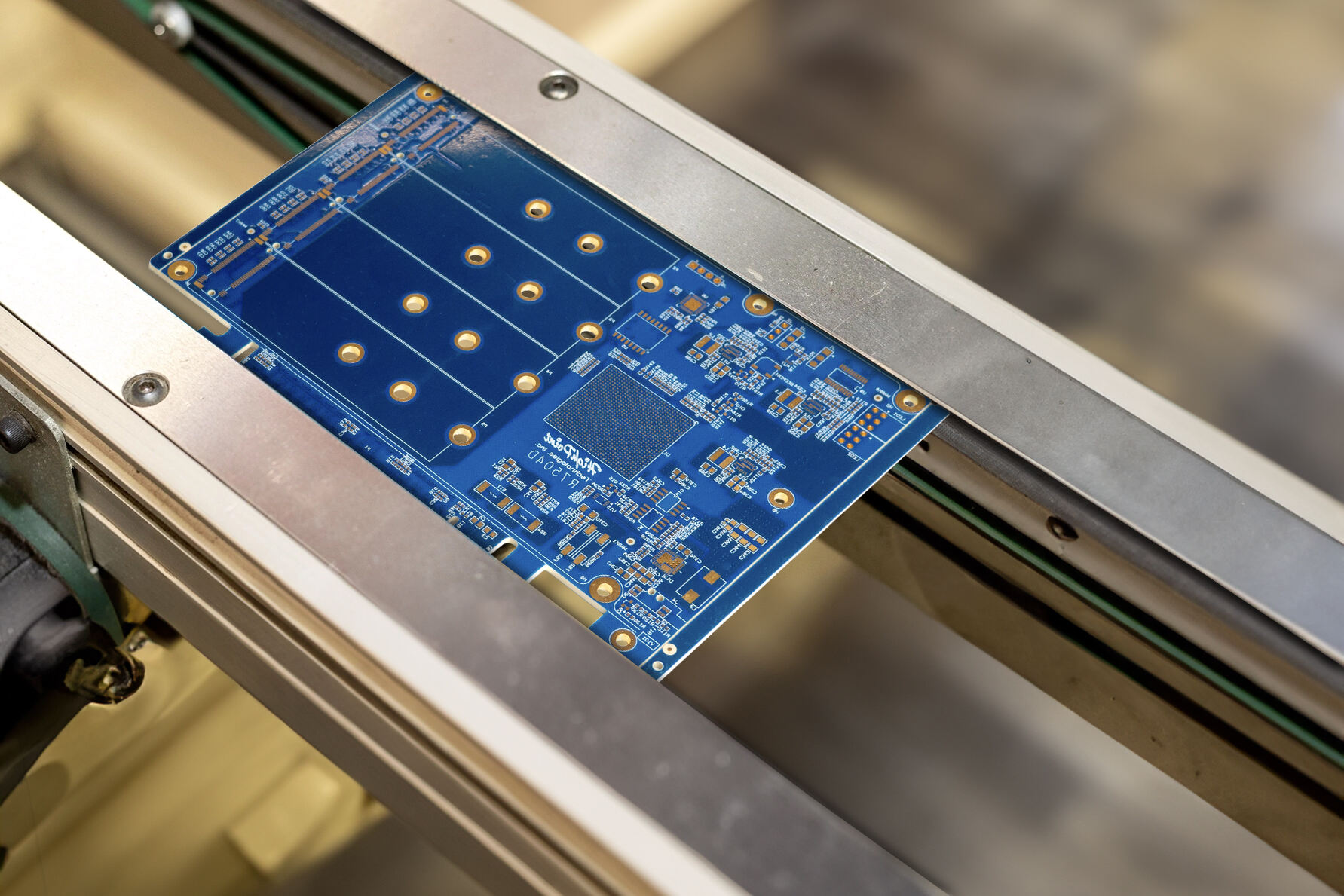

pcb manufacturing factory

A PCB manufacturing factory represents a state-of-the-art facility dedicated to producing printed circuit boards that form the backbone of modern electronics. These specialized facilities employ advanced automation systems and precision equipment to transform raw materials into high-quality circuit boards. The manufacturing process encompasses multiple sophisticated stages, including design verification, material preparation, imaging, etching, drilling, and testing. Modern PCB factories utilize computer-controlled machinery for ultra-precise component placement and cutting-edge inspection systems that ensure quality at every production phase. The facility's clean room environments maintain strict control over temperature, humidity, and particulate matter, essential for producing reliable circuit boards. These factories can handle various PCB types, from simple single-layer boards to complex multilayer designs, serving industries ranging from consumer electronics to aerospace applications. The integration of smart manufacturing principles allows for real-time production monitoring, quality control, and efficient resource management, resulting in consistent, high-quality output with minimal defects.