rigid flex pcb supplier

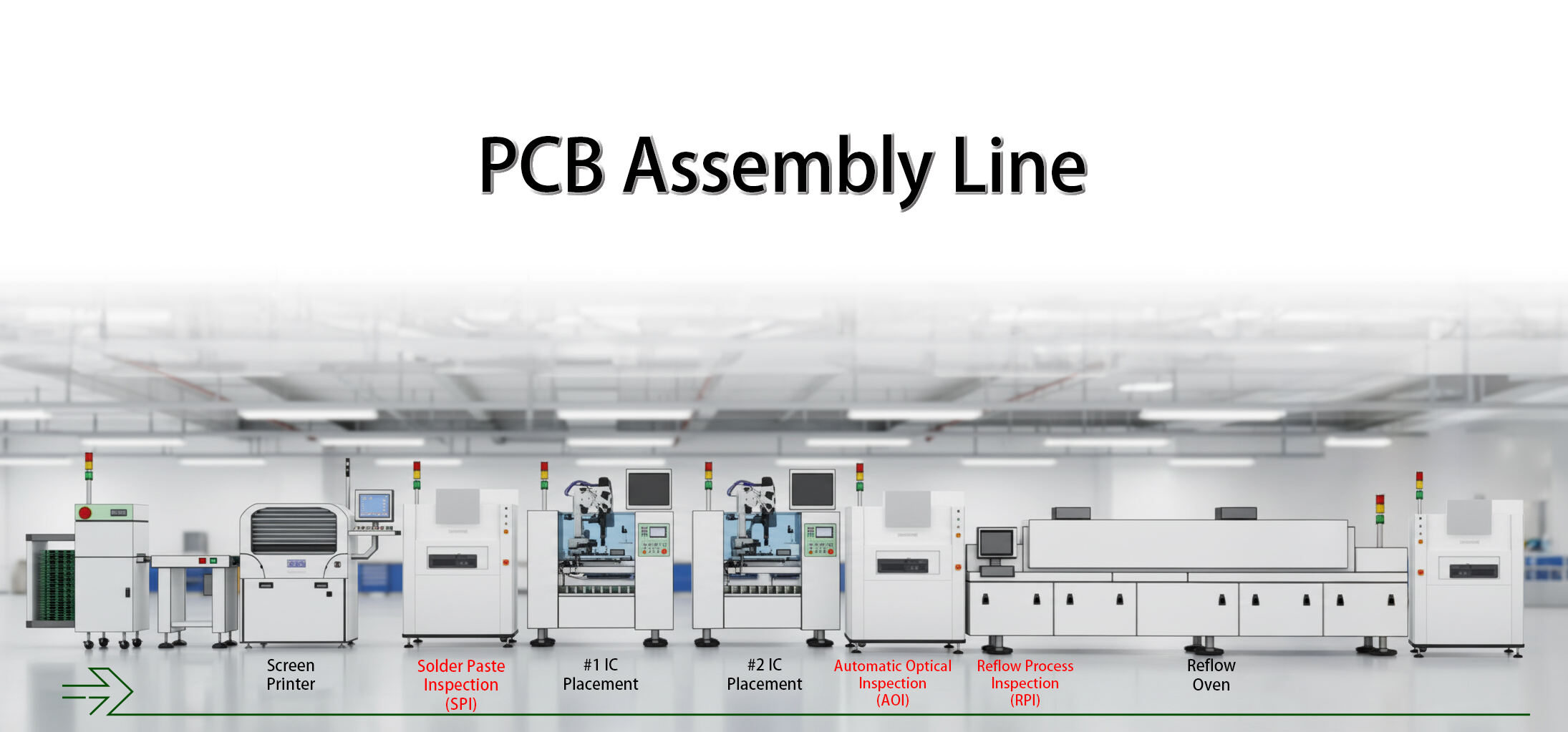

A rigid flex PCB supplier represents a crucial partner in modern electronics manufacturing, specializing in the production of hybrid circuit boards that combine rigid and flexible circuit technologies. These suppliers leverage advanced manufacturing capabilities to create boards that seamlessly integrate rigid sections for component mounting with flexible sections that enable dynamic movement and interconnection. Their expertise encompasses comprehensive design support, material selection, and quality control processes that ensure the production of reliable, high-performance circuit solutions. The supplier typically maintains state-of-the-art facilities equipped with precision manufacturing equipment, including advanced lamination systems, laser drilling machines, and automated optical inspection systems. They offer various services from prototype development to full-scale production, utilizing materials such as polyimide, FR4, and specialized adhesives to achieve optimal performance characteristics. The supplier's capabilities extend to implementing complex designs with multiple layers, controlled impedance requirements, and fine-line technology, while maintaining strict adherence to industry standards and specifications. Their solutions find applications across diverse sectors, including aerospace, medical devices, telecommunications, and consumer electronics, where space constraints and reliability requirements demand innovative interconnect solutions.