pcb manufacturing cost

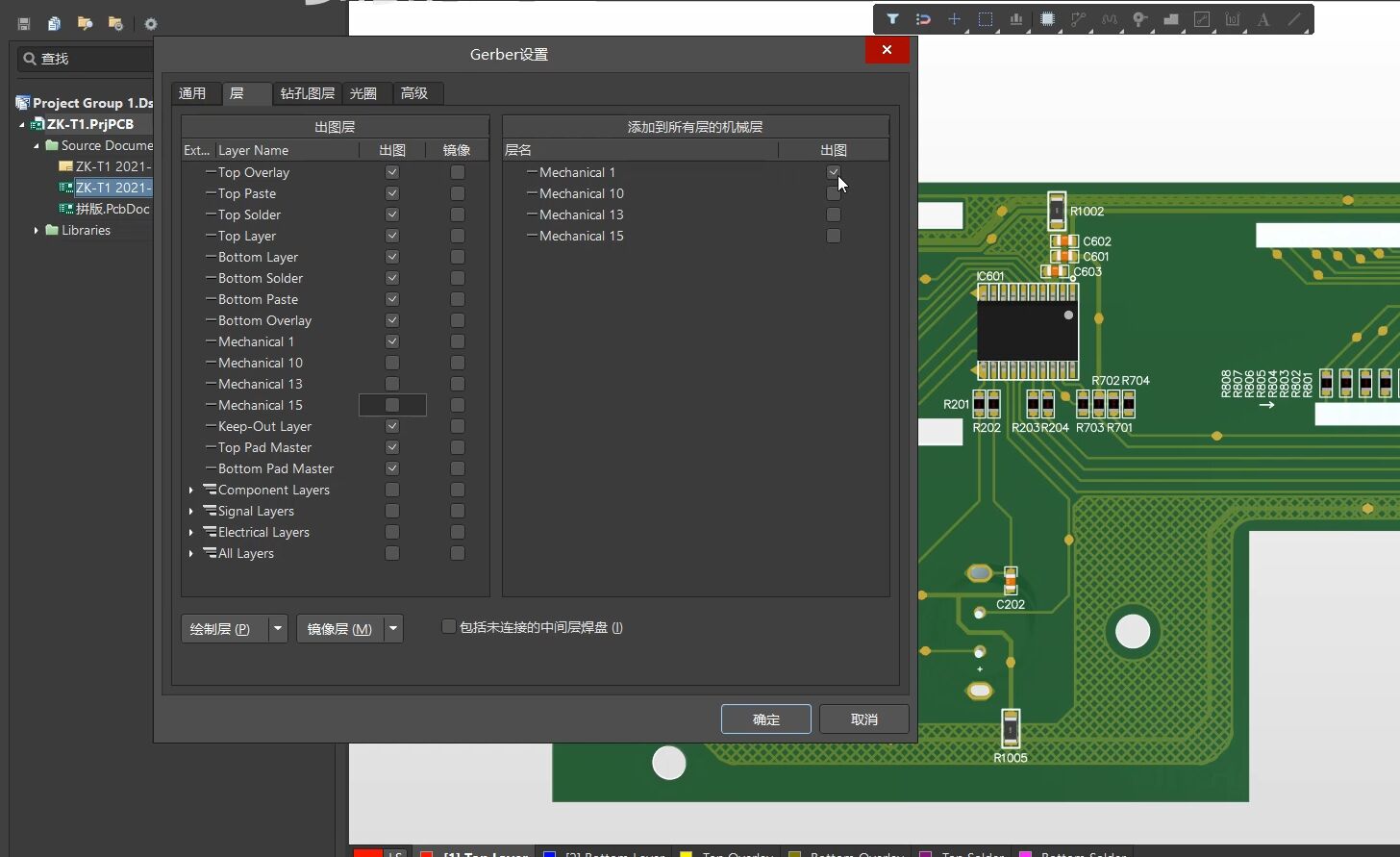

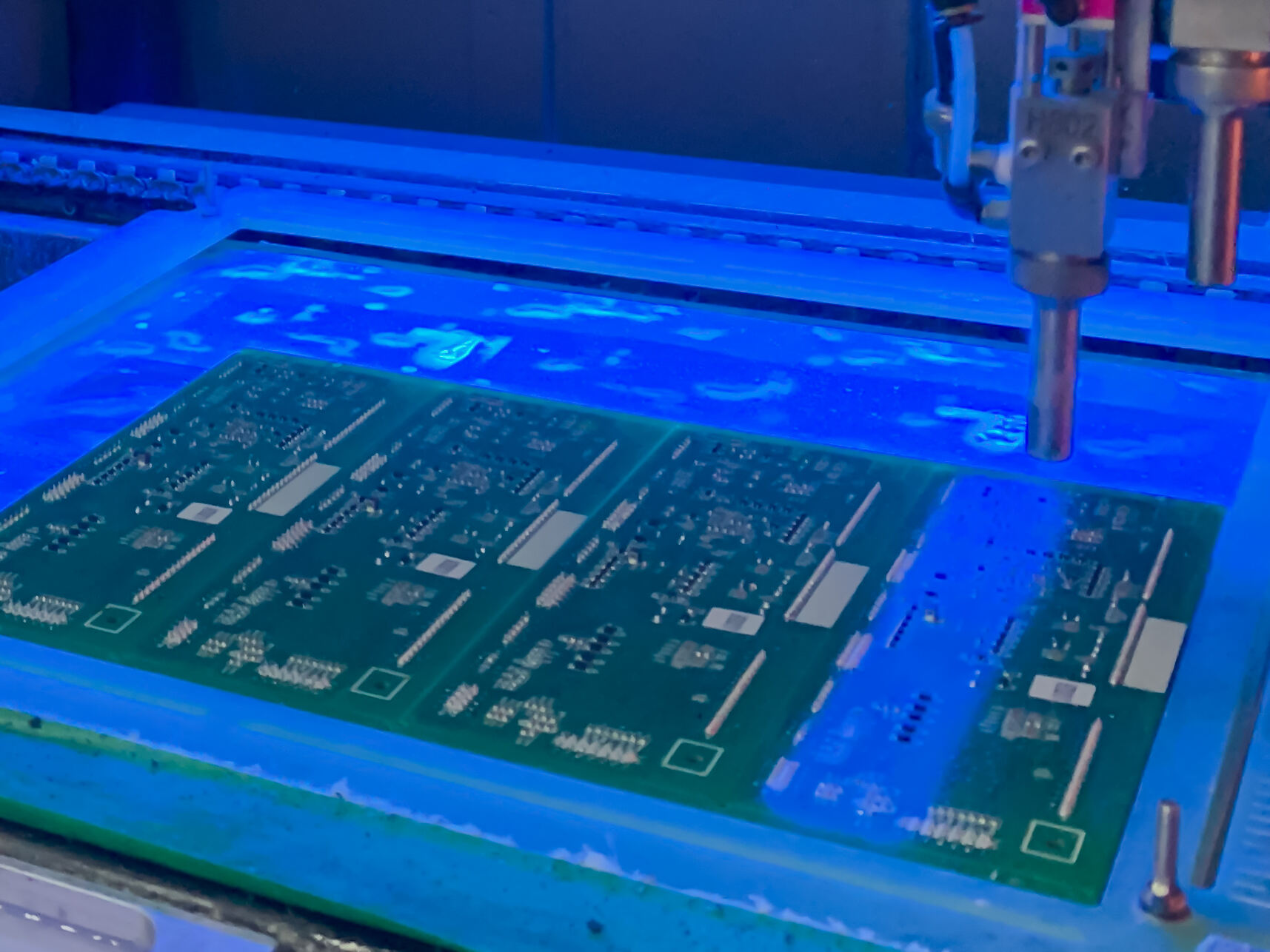

PCB manufacturing cost encompasses all expenses involved in producing printed circuit boards, from design to final assembly. This crucial aspect of electronics production includes material costs, labor expenses, equipment investment, and overhead charges. The cost structure typically varies based on board complexity, size, layer count, and production volume. Modern PCB manufacturing employs advanced technologies like automated optical inspection (AOI), computer-aided manufacturing (CAM), and surface mount technology (SMT), which influence the overall cost. Material selection, including substrate type, copper weight, and surface finish, significantly impacts pricing. Additionally, manufacturing costs consider factors such as minimum trace width, hole size, board thickness, and special requirements like impedance control or high-frequency materials. The production process involves multiple stages: design verification, material preparation, imaging, etching, drilling, plating, solder mask application, and final testing. Each stage contributes to the total cost, with complexity and precision requirements directly affecting the price point. Understanding these cost components is essential for both manufacturers and customers to optimize production efficiency while maintaining quality standards.