pad in via

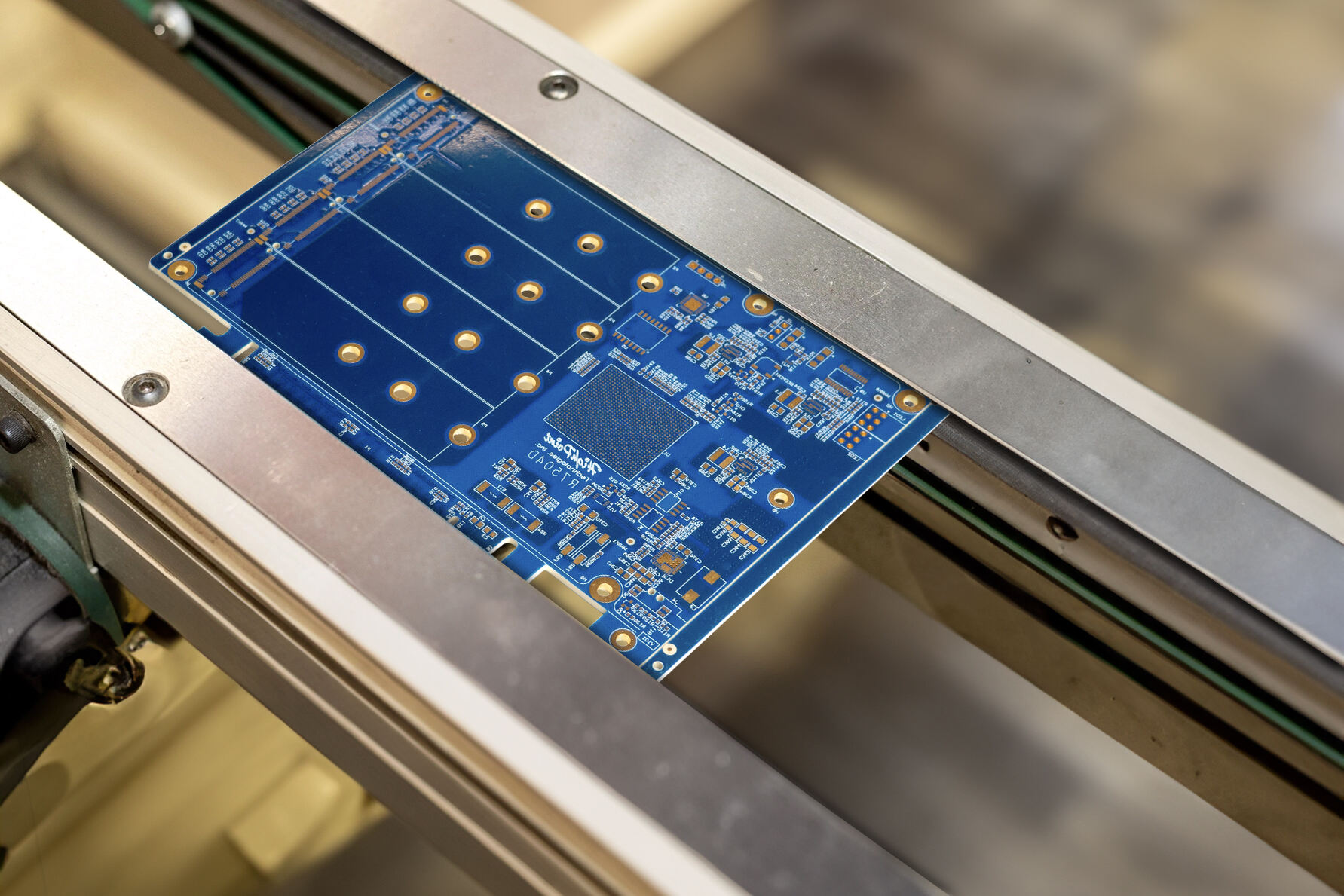

A pad in via is a crucial component in printed circuit board (PCB) design and manufacturing that serves as an electrical connection point between different layers of a circuit board. This specialized structure consists of a conductive pad surrounding a plated through-hole, creating a reliable electrical pathway while providing mechanical stability. The pad in via technology enables complex multilayer PCB designs by facilitating vertical interconnections between various circuit layers. The structure typically includes a copper pad on the surface layers connected to a metallized hole that extends through the board. Modern pad in via designs incorporate advanced features such as thermal relief patterns to manage heat distribution and optimize soldering processes. These components are essential for creating high-density electronic devices, as they allow for efficient use of board space while maintaining signal integrity. The technology has evolved to support various applications, from simple two-layer boards to sophisticated high-frequency designs, offering flexibility in PCB layout and improved manufacturing yields.