pcb board factory

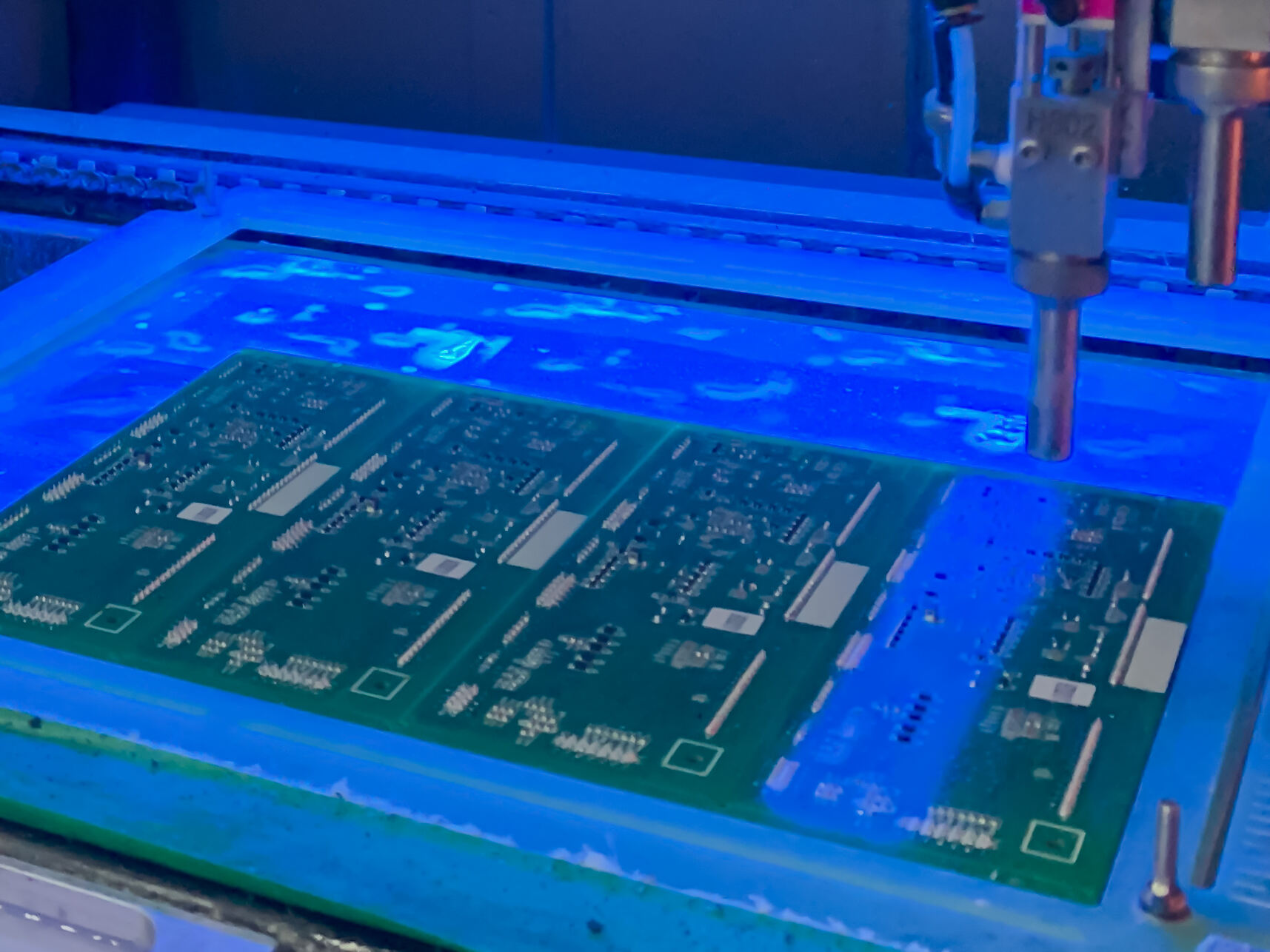

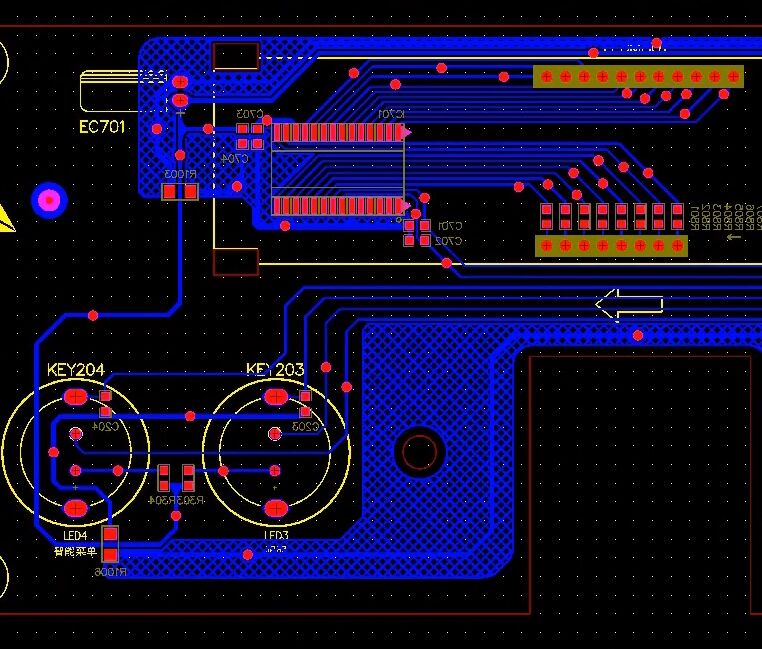

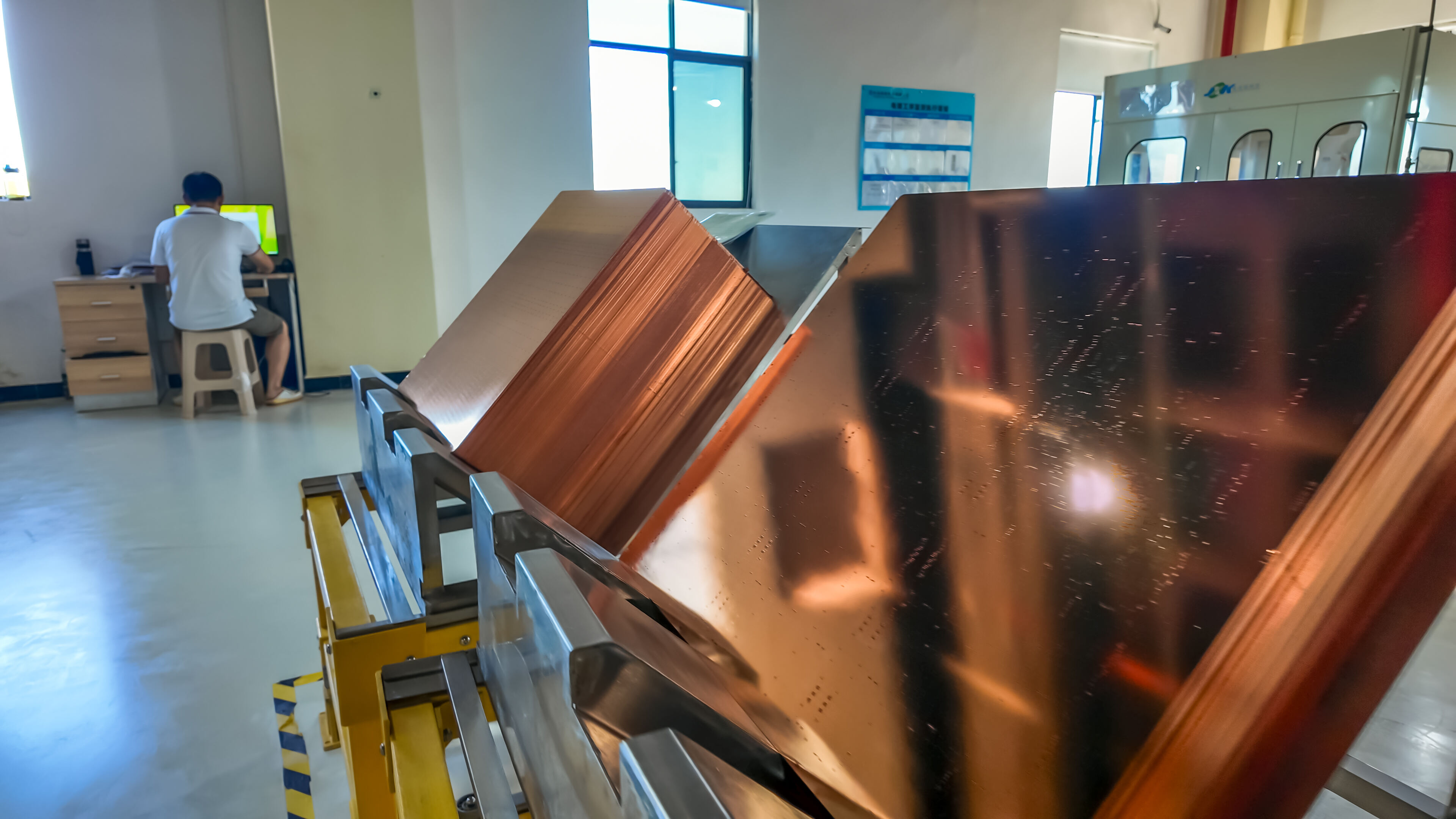

A PCB board factory represents a cutting-edge manufacturing facility dedicated to producing printed circuit boards that serve as the foundation of modern electronics. These specialized facilities incorporate state-of-the-art equipment and precision engineering processes to create circuit boards that meet diverse industry requirements. The factory utilizes advanced manufacturing techniques, including automated assembly lines, precision drilling systems, and multi-layer lamination processes. Quality control measures are implemented at every production stage, from initial design verification to final testing, ensuring each board meets stringent industry standards. The facility's capabilities typically extend to producing various PCB types, including single-sided, double-sided, and multi-layer boards, with options for flexible and rigid-flex configurations. Modern PCB factories employ sophisticated surface mount technology (SMT) and through-hole technology (THT) to accommodate different component mounting requirements. The factory's operations encompass the entire manufacturing process, from computer-aided design (CAD) file processing to final quality inspection, including copper cleaning, photoresist application, etching, and solder mask application. These facilities also maintain strict environmental controls to ensure optimal conditions for precision manufacturing, with cleanroom environments for sensitive processes. The factory's comprehensive capabilities enable it to serve diverse industries, including telecommunications, automotive electronics, medical devices, and consumer electronics, providing customized solutions for specific application requirements.