prototype pcb assembly manufacturer

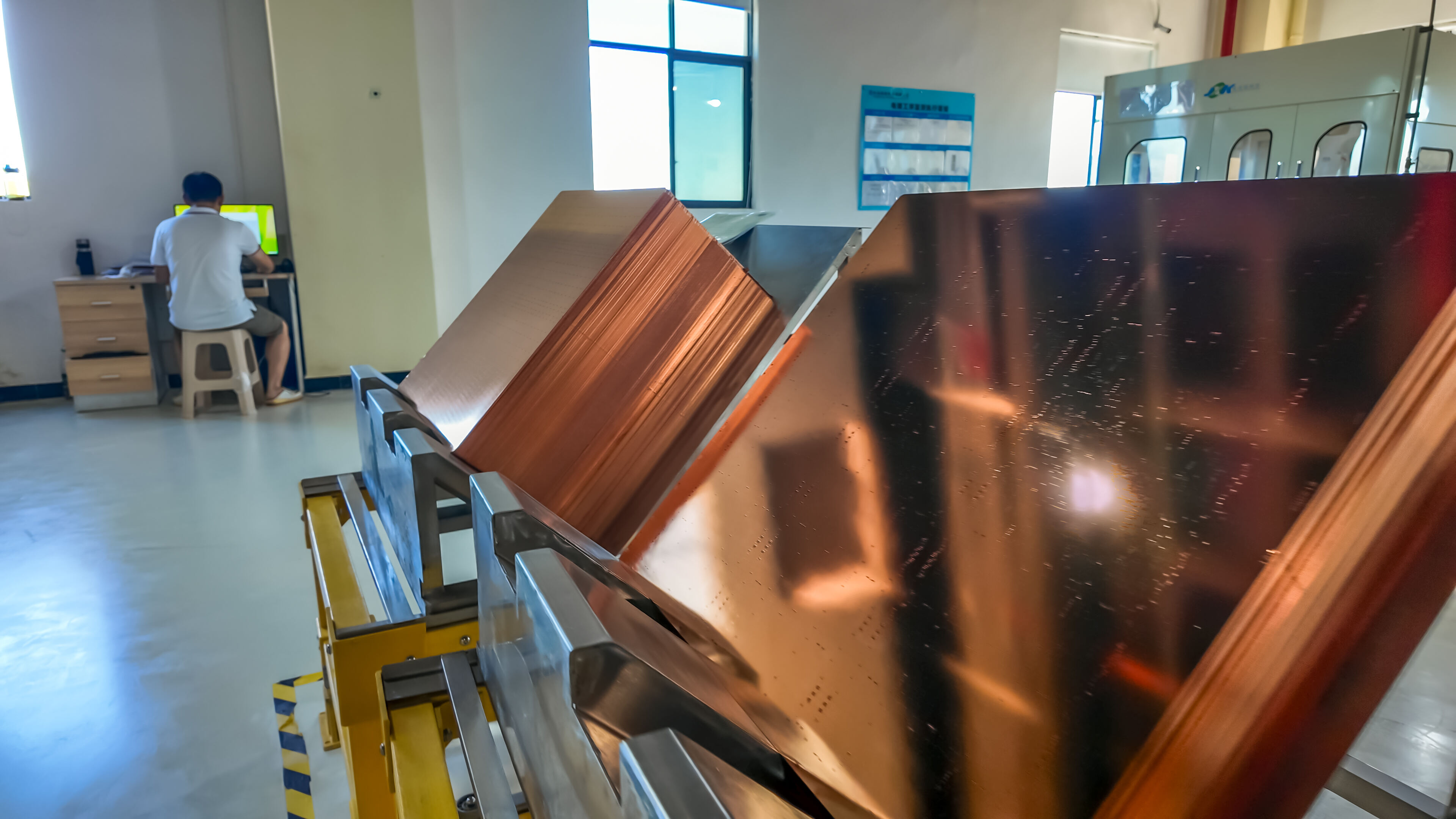

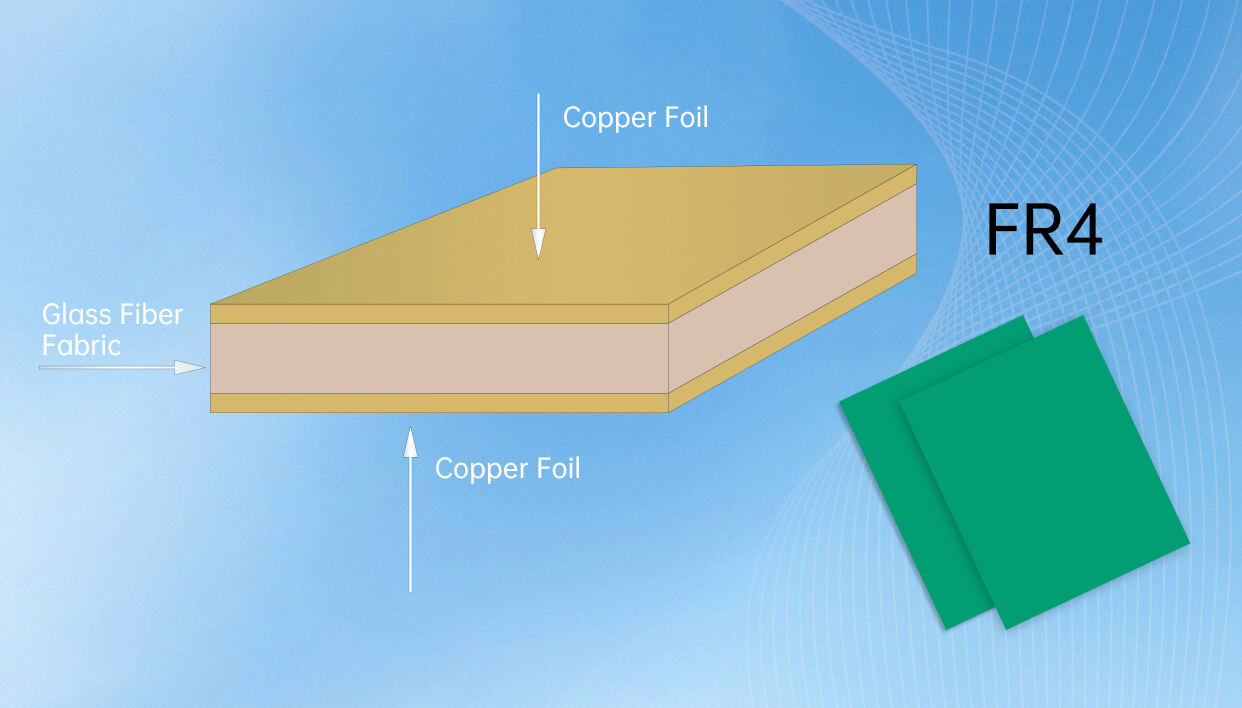

A prototype PCB assembly manufacturer specializes in producing small-batch, high-quality printed circuit boards for product development and testing phases. These manufacturers utilize advanced equipment and skilled technicians to transform circuit designs into functional boards through a comprehensive process that includes component placement, soldering, and quality testing. They employ state-of-the-art surface mount technology (SMT) and through-hole assembly techniques to accommodate various component types and board complexities. The facilities are equipped with automated pick-and-place machines, reflow ovens, and inspection systems to ensure precise assembly and consistent quality. These manufacturers offer critical services such as design for manufacturability (DFM) review, component sourcing, and testing protocols. They can handle both simple and complex multilayer boards, working with different substrate materials and component densities. Their expertise extends to specialized requirements like flex circuits, rigid-flex boards, and high-frequency applications. Quality control measures include automated optical inspection (AOI), X-ray inspection for hidden solder joints, and functional testing to verify board performance. The ability to quickly turn around prototypes allows companies to validate designs and make necessary modifications before moving to full-scale production.