industrial pcb manufacturing

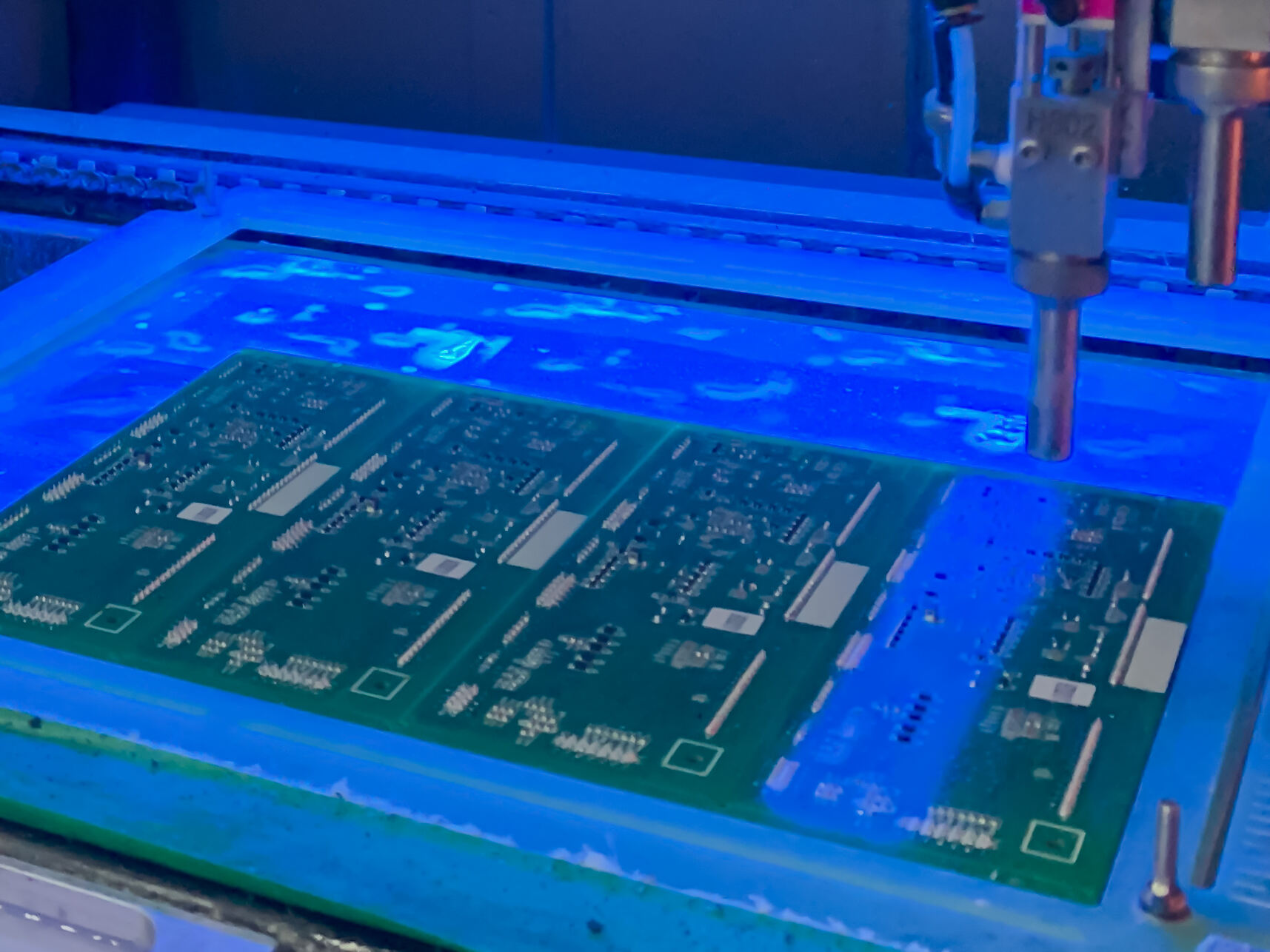

Industrial PCB manufacturing represents a sophisticated process that combines precision engineering with advanced technology to produce high-quality printed circuit boards for various industrial applications. This comprehensive manufacturing process encompasses multiple stages, from initial design verification to final quality testing. Modern industrial PCB manufacturing facilities utilize state-of-the-art equipment for precise layer alignment, automated optical inspection, and advanced surface mount technology. The process includes critical steps such as photolithography, etching, drilling, plating, and solder mask application, ensuring consistent quality and reliability. These facilities can handle various PCB types, including multi-layer, rigid, flex, and rigid-flex boards, catering to diverse industrial needs. The manufacturing process incorporates strict quality control measures, adhering to international standards such as IPC and ISO certifications. Advanced manufacturing capabilities enable the production of complex designs with fine pitch components, blind and buried vias, and specialized surface finishes. This sophisticated approach ensures the final products meet the demanding requirements of industrial applications, from automotive systems to medical devices and telecommunications equipment.