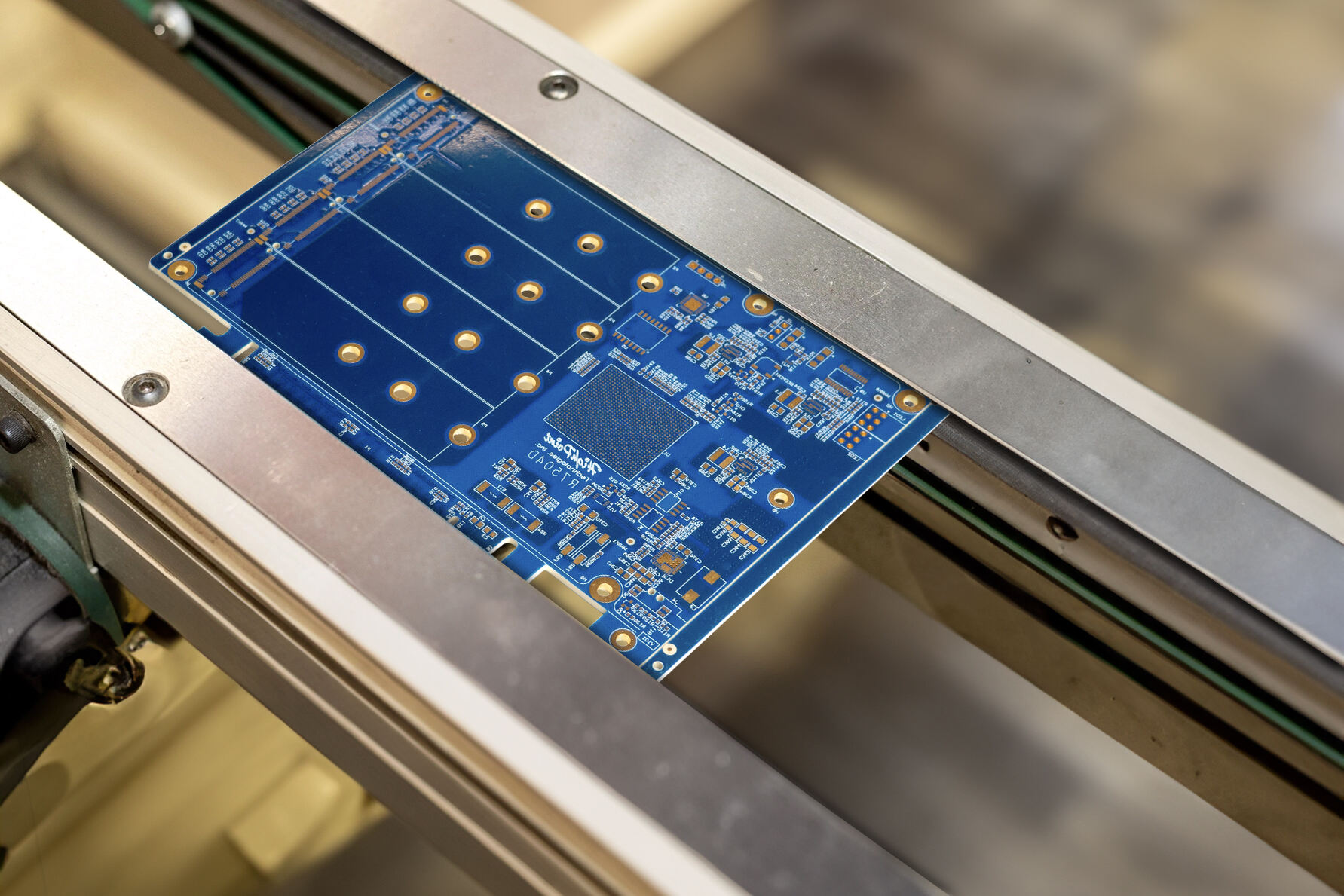

fast turn pcb

Fast turn PCB (Printed Circuit Board) represents a cutting-edge solution in electronic manufacturing that prioritizes rapid production without compromising quality. These boards are specifically designed and manufactured using advanced technologies and streamlined processes to meet urgent market demands and tight project deadlines. The manufacturing process incorporates state-of-the-art equipment and automated systems that enable quick turnaround times, typically ranging from 24 hours to several days, depending on the complexity and specifications of the design. Fast turn PCBs maintain high precision and reliability while significantly reducing the traditional production timeline. They support various layer counts, from simple single-layer designs to complex multilayer configurations, and can accommodate different board materials, including FR4, flexible substrates, and high-frequency materials. These PCBs are extensively used in prototyping, small-batch production, and time-critical projects across multiple industries, including aerospace, telecommunications, medical devices, and consumer electronics. The manufacturing process includes rapid design verification, automated testing, and quality assurance protocols to ensure that each board meets the required specifications and industry standards.