pcba manufacturing factory

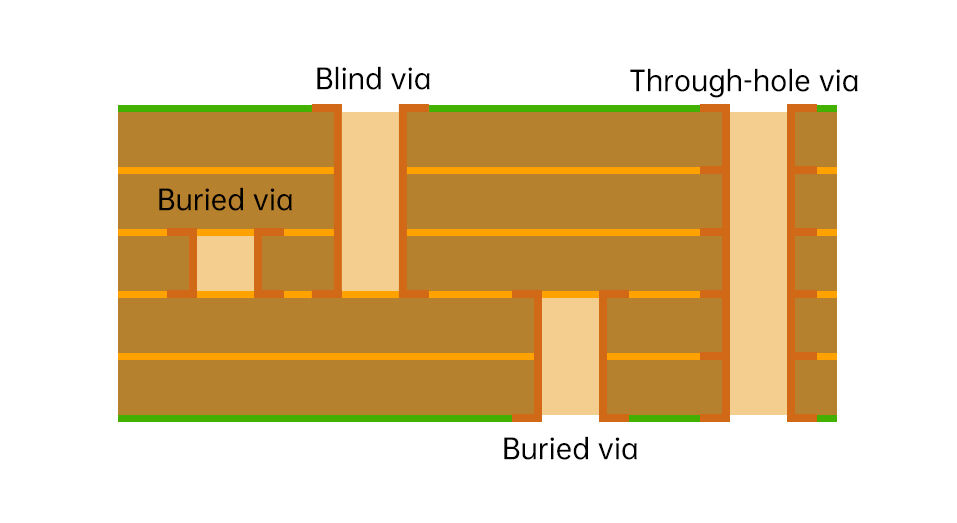

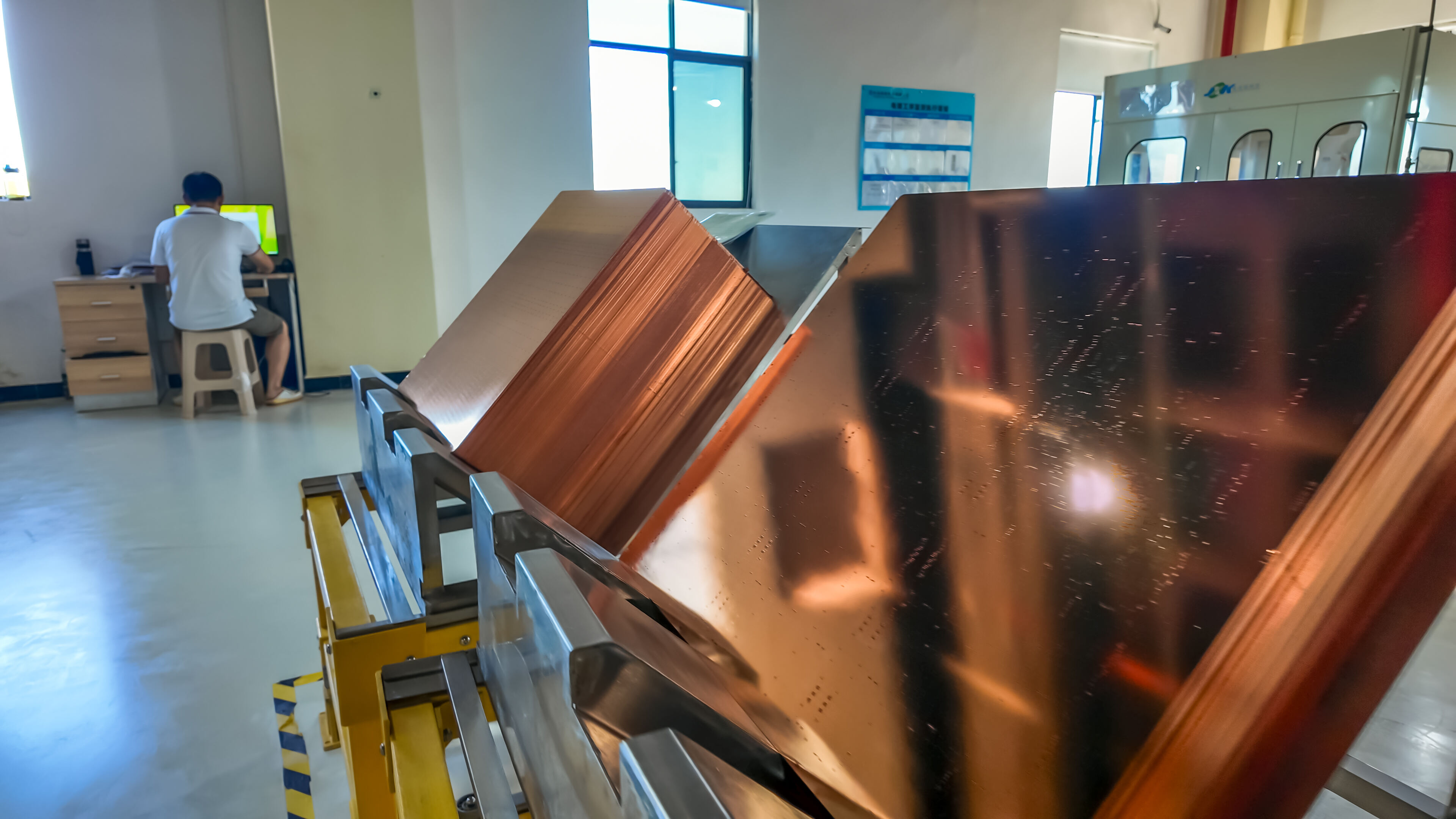

A PCBA manufacturing factory represents a cutting-edge facility dedicated to the production of Printed Circuit Board Assemblies, combining advanced automation technology with precision engineering. These state-of-the-art facilities house comprehensive production lines that handle everything from surface mount technology (SMT) to through-hole assembly processes. The factory encompasses multiple specialized zones, including clean rooms for sensitive component handling, automated pick-and-place machinery for component mounting, and sophisticated testing areas for quality assurance. Modern PCBA facilities feature intelligent production management systems that oversee real-time monitoring of assembly processes, component inventory tracking, and quality control measures. They utilize advanced equipment such as automated optical inspection (AOI) systems, X-ray inspection machines, and in-circuit testers to ensure product reliability. The factory's capabilities typically extend to handling various board sizes and complexities, from simple single-layer boards to complex multilayer designs. Environmental control systems maintain optimal temperature, humidity, and cleanliness levels throughout the facility, ensuring consistent production quality. These factories serve diverse industries, including consumer electronics, automotive, medical devices, and industrial equipment, with the flexibility to accommodate both high-volume production runs and specialized prototype projects.