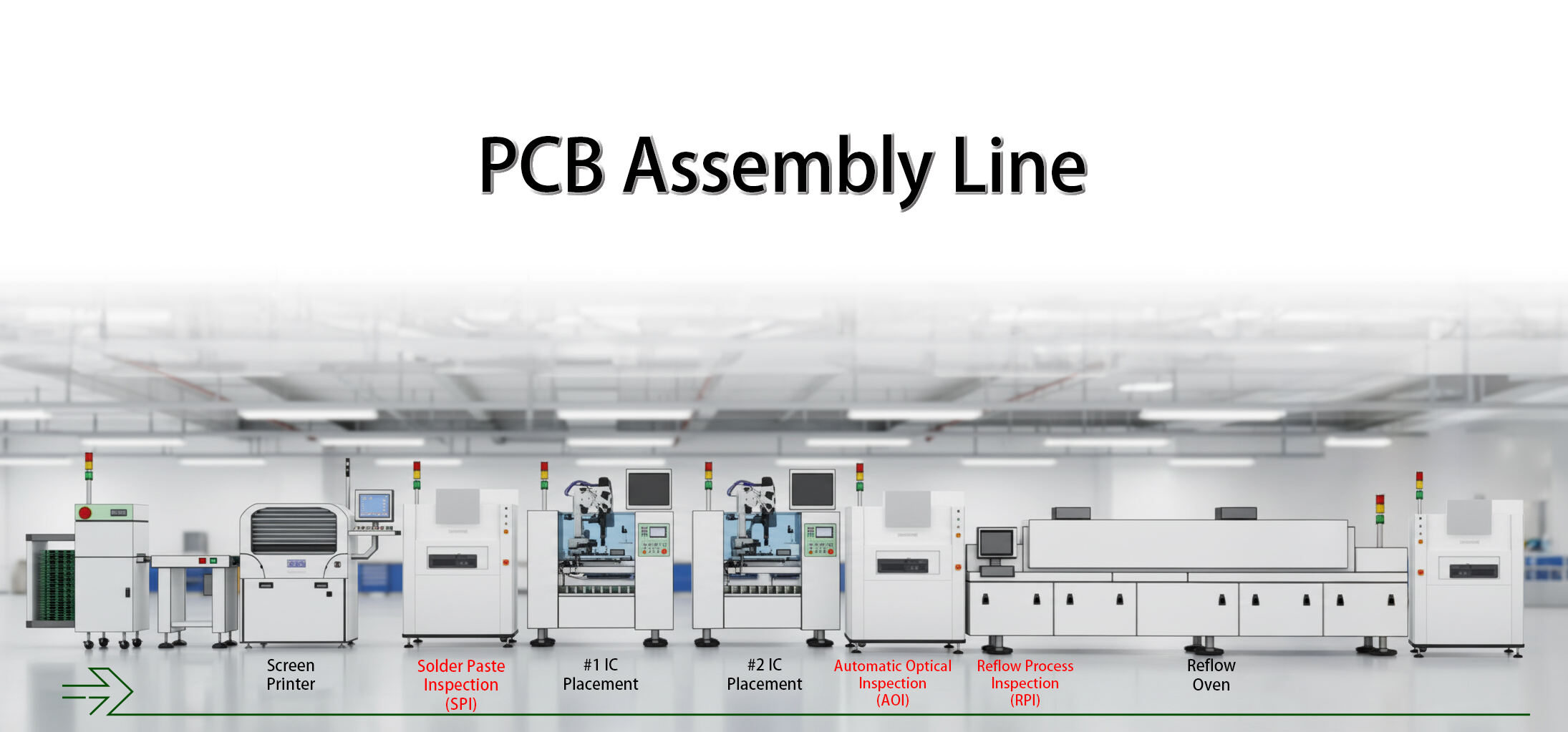

pcb stencil

A PCB stencil is a precision-engineered tool essential in the surface mount technology (SMT) assembly process. This thin metal sheet, typically manufactured from stainless steel or polyimide, features precisely cut apertures that align with the solder pad patterns on a printed circuit board. The primary function of a PCB stencil is to facilitate accurate and consistent solder paste deposition during the PCB assembly process. Using advanced laser cutting technology, these stencils are crafted to exact specifications, ensuring precise alignment with board components. The thickness of the stencil, usually ranging from 0.1mm to 0.2mm, is carefully calculated to deliver the optimal amount of solder paste for different component types. Modern PCB stencils incorporate sophisticated design features such as nano-coating for enhanced paste release and stepped apertures for improved printing performance. They are widely used in electronics manufacturing, from small-batch prototyping to high-volume production, and are crucial for achieving reliable solder joints in electronic assemblies.