fast pcb manufacturing

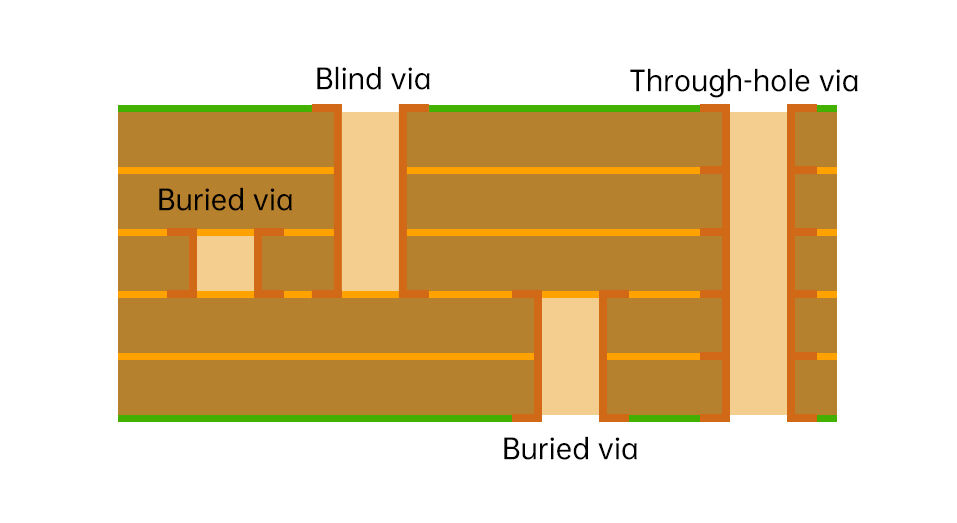

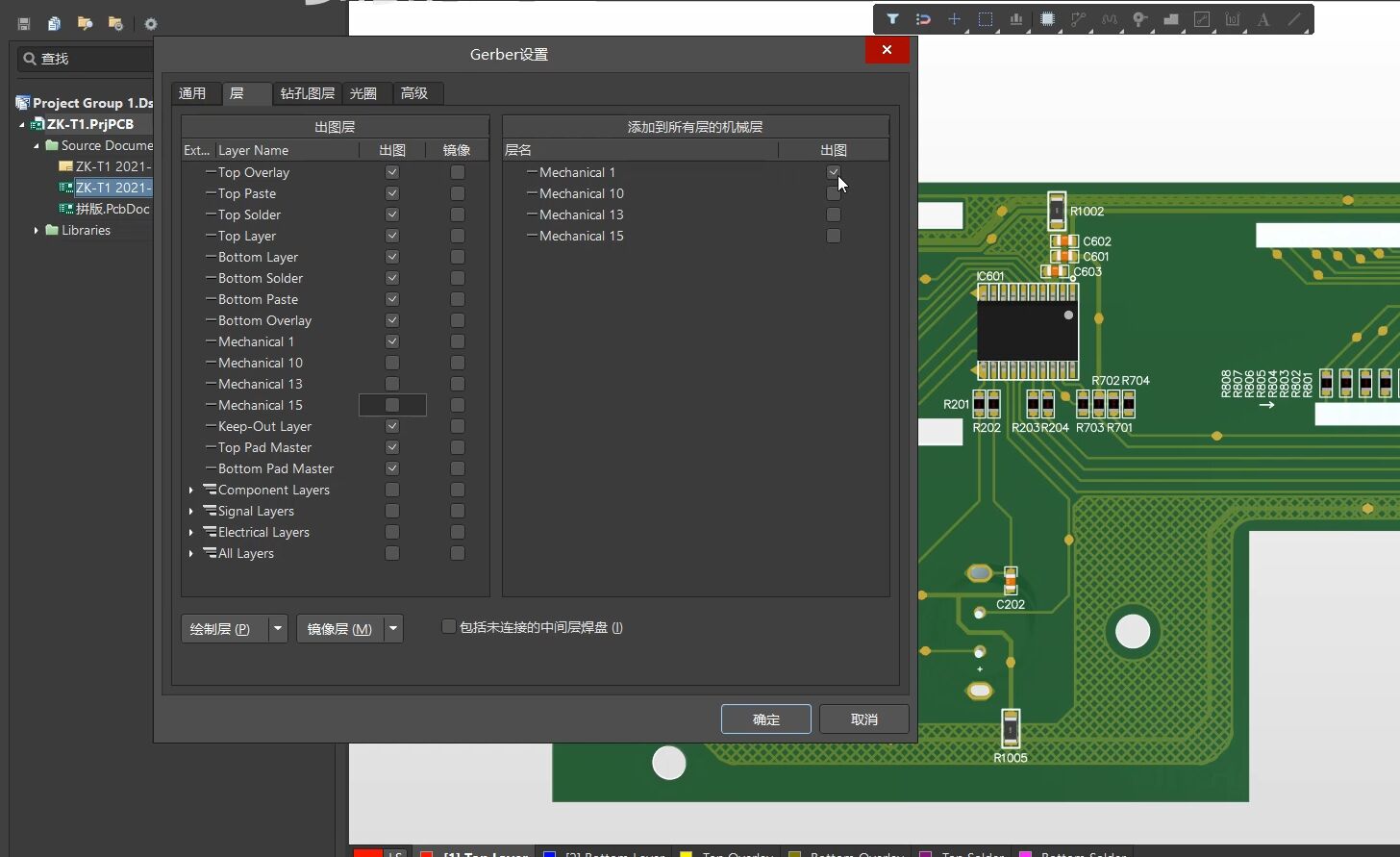

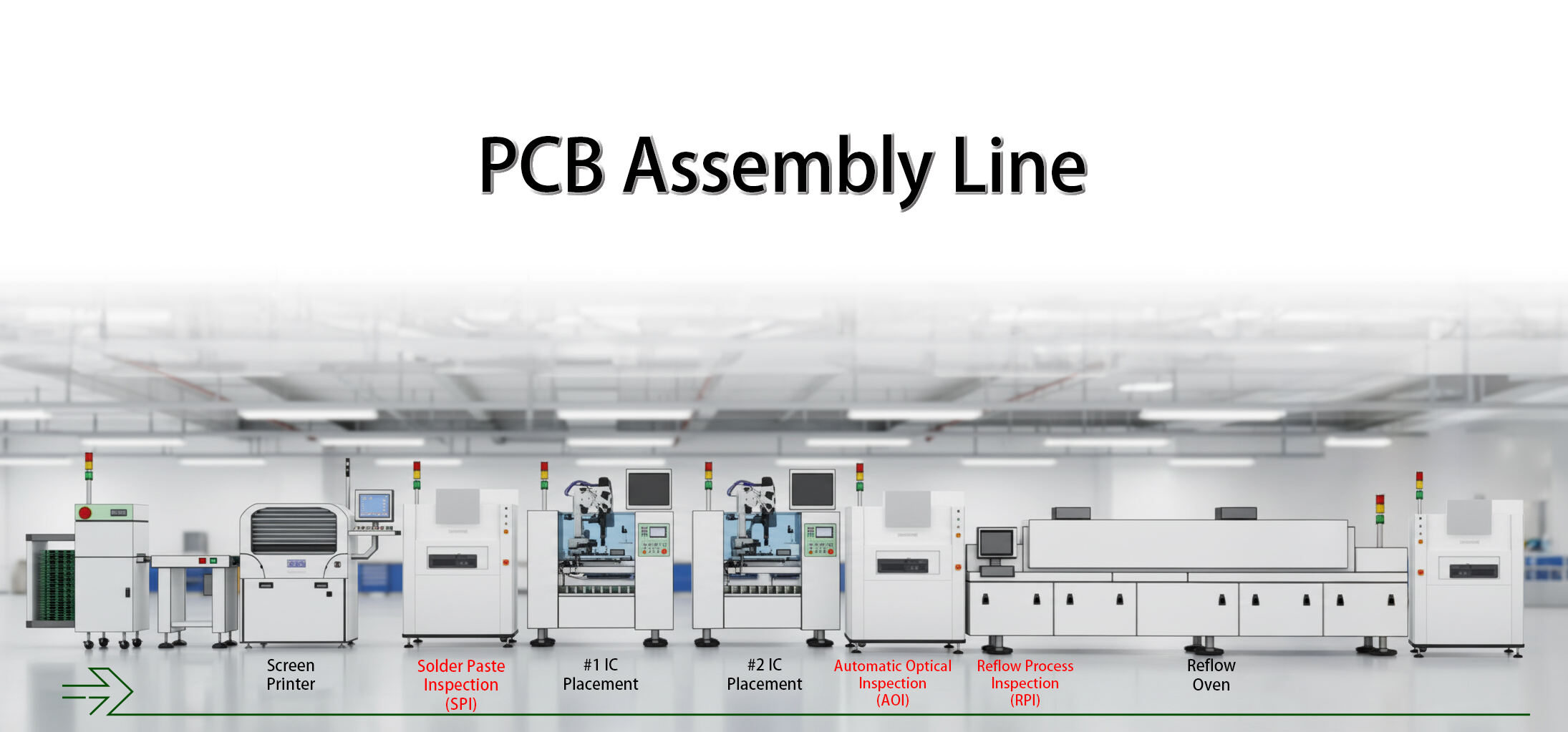

Fast PCB manufacturing represents a cutting-edge approach to producing printed circuit boards with unprecedented speed and precision. This modern manufacturing process combines advanced automation, sophisticated design software, and state-of-the-art production equipment to deliver high-quality PCBs in remarkably short timeframes. The process encompasses several critical stages, including design verification, material selection, layer stacking, drilling, plating, etching, and testing, all optimized for rapid turnaround. Advanced manufacturing facilities utilize computer-controlled equipment and automated quality control systems to ensure consistent quality while maintaining speed. This technology enables manufacturers to handle both simple and complex PCB designs, from single-layer to multilayer boards, with various substrate materials and specifications. The integration of smart factory concepts and Industry 4.0 principles allows for real-time monitoring and adjustment of production parameters, ensuring optimal results. Fast PCB manufacturing serves diverse industries, including electronics, telecommunications, automotive, aerospace, and medical devices, where time-to-market is crucial. This manufacturing approach also accommodates various board sizes, thicknesses, and special requirements such as impedance control and high-frequency applications, making it versatile enough to meet diverse customer needs.