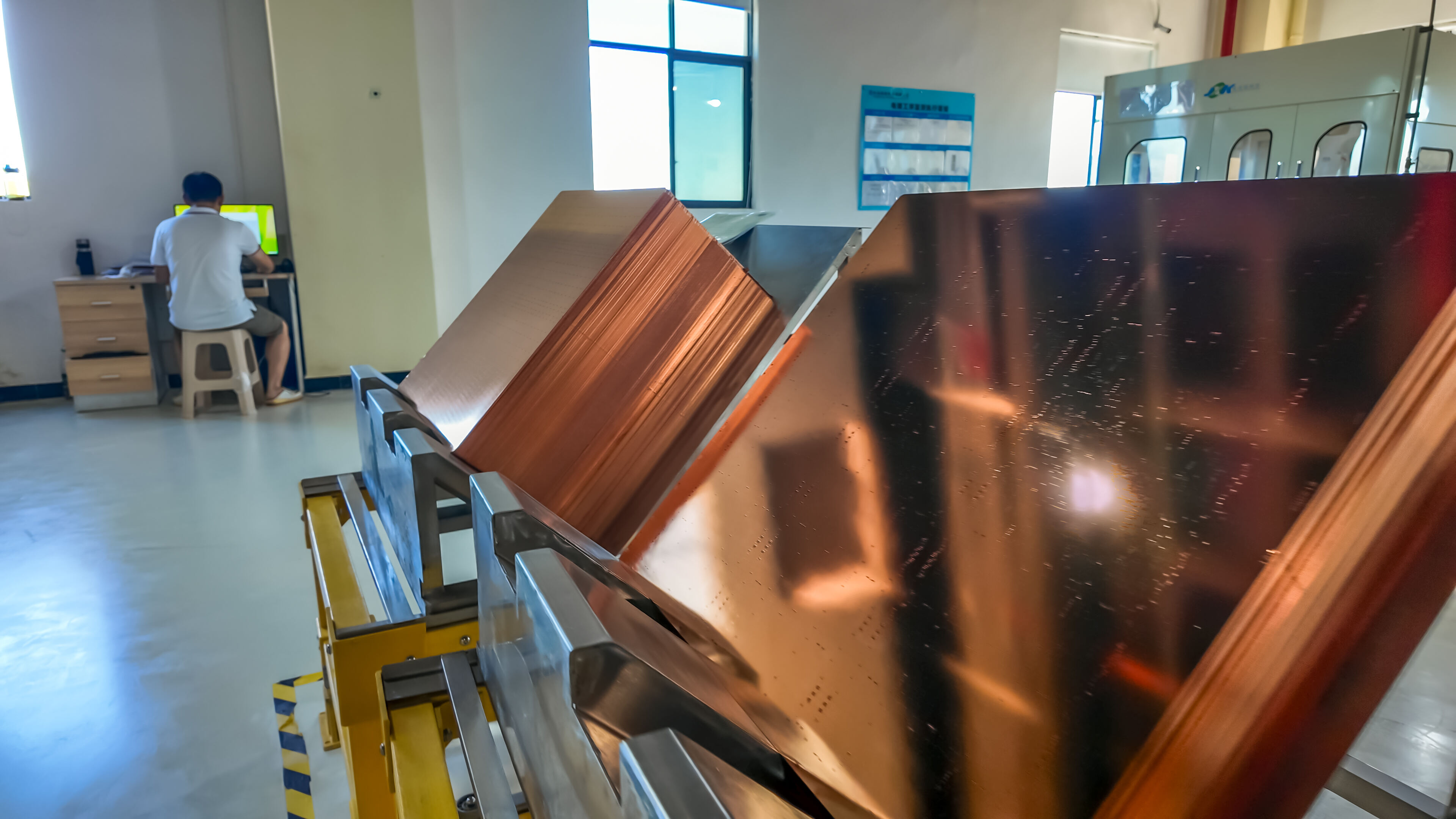

smt pcb assembly factory

A SMT PCB assembly factory represents a state-of-the-art manufacturing facility dedicated to the precise production of electronic circuit boards using Surface Mount Technology. These facilities integrate advanced automated systems, including pick-and-place machines, reflow ovens, and automated optical inspection equipment to ensure high-quality PCB assembly. The factory's core operations encompass component placement, soldering, testing, and quality control processes, all conducted in a controlled environment to maintain optimal production conditions. Modern SMT PCB assembly factories utilize sophisticated software systems for production planning, inventory management, and real-time monitoring of assembly lines. They typically feature multiple production lines capable of handling various board sizes and complexities, from simple single-layer boards to complex multilayer designs. The facility's capabilities extend to both prototype development and high-volume manufacturing, with flexibility to accommodate different customer requirements. Quality control measures include automated optical inspection (AOI), X-ray inspection for hidden solder joints, and functional testing to ensure each assembled PCB meets specified performance standards. Environmental controls maintain proper temperature, humidity, and cleanliness levels to prevent static discharge and contamination that could affect product quality. These facilities also implement strict inventory management systems to ensure component availability and traceability throughout the production process.