prototype pcb assembly

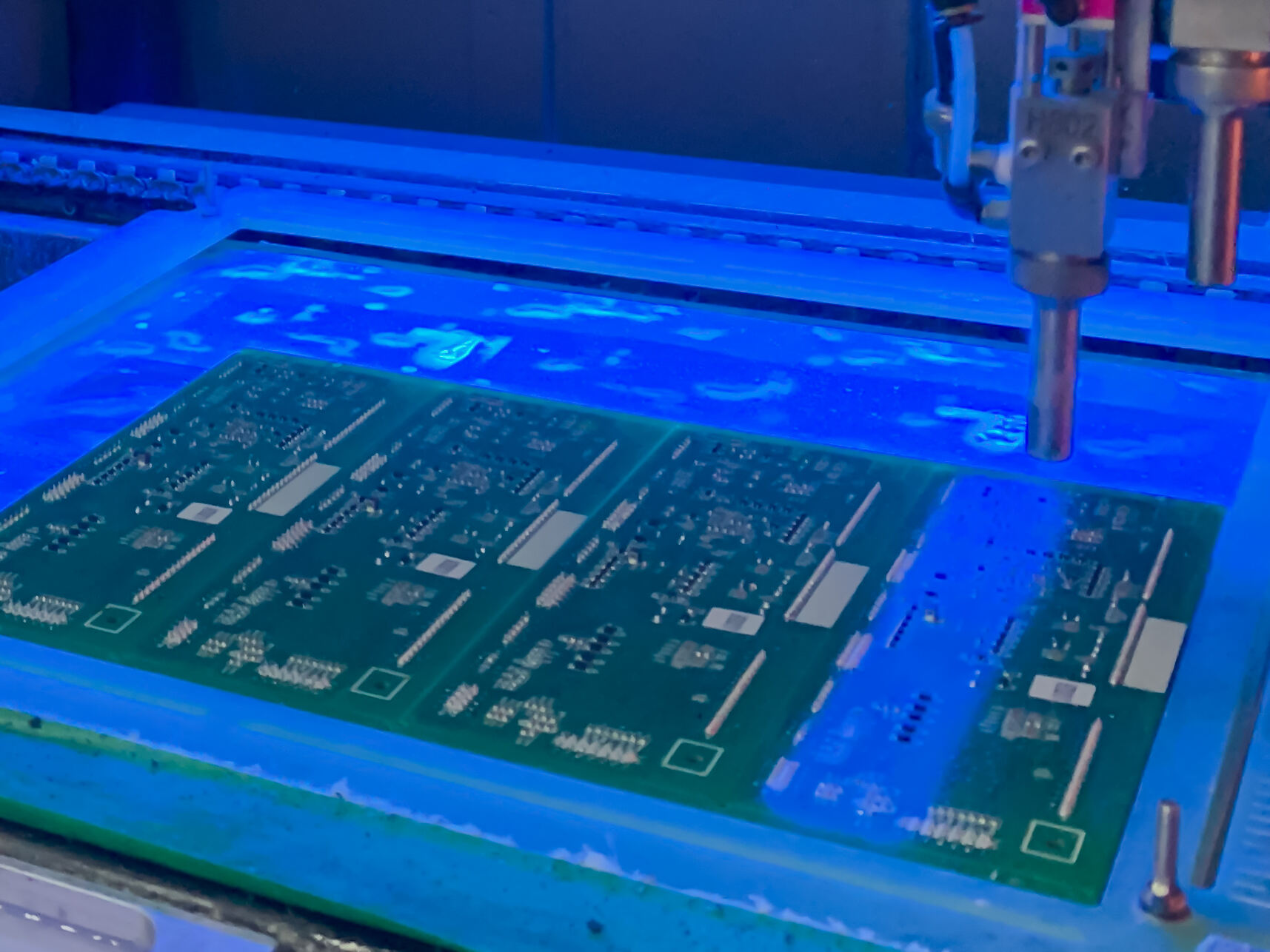

Prototype PCB assembly represents a crucial phase in electronics development, combining cutting-edge manufacturing techniques with precision engineering to create functional circuit board prototypes. This process encompasses multiple stages, from initial design verification to component placement and soldering, ensuring that electronic devices function as intended before mass production. The assembly process utilizes advanced surface mount technology (SMT) and through-hole mounting techniques, allowing for the integration of various electronic components onto a single board. Modern prototype PCB assembly facilities employ automated pick-and-place machines, reflow ovens, and inspection systems to maintain high quality and accuracy. These assemblies serve as essential testing platforms for new electronic products, enabling engineers to validate designs, identify potential issues, and make necessary modifications. The versatility of prototype PCB assembly supports applications across numerous industries, including consumer electronics, medical devices, automotive systems, and aerospace technology. Quality control measures, including automated optical inspection (AOI) and X-ray inspection, ensure that each prototype meets exact specifications and functions reliably.