prototype pcb board manufacturer

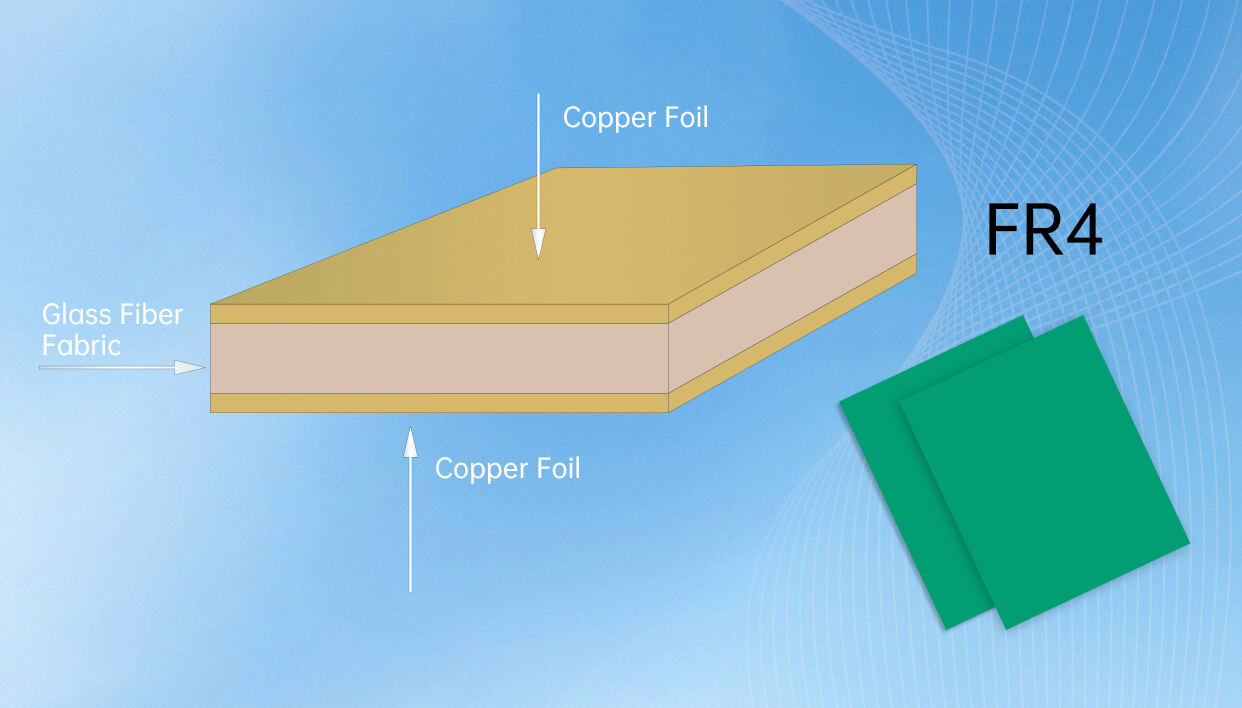

A prototype PCB board manufacturer specializes in producing high-quality printed circuit boards for product development and testing phases. These manufacturers utilize state-of-the-art equipment and advanced manufacturing processes to create precise, reliable PCB prototypes that meet exact specifications. They offer comprehensive services including design review, DFM analysis, material selection, and quality testing. The facilities typically feature automated assembly lines, advanced inspection systems, and clean room environments to ensure optimal production conditions. These manufacturers can handle various PCB types, from simple single-layer boards to complex multilayer designs, accommodating different materials and specifications. They provide quick turnaround times, often offering expedited services for urgent projects, while maintaining strict quality control measures throughout the manufacturing process. Modern prototype PCB manufacturers also employ sophisticated software tools for design verification and optimization, ensuring that each board meets industry standards and customer requirements. They typically offer additional services such as impedance control, surface finishing options, and various board thicknesses to accommodate different applications, from consumer electronics to industrial equipment.