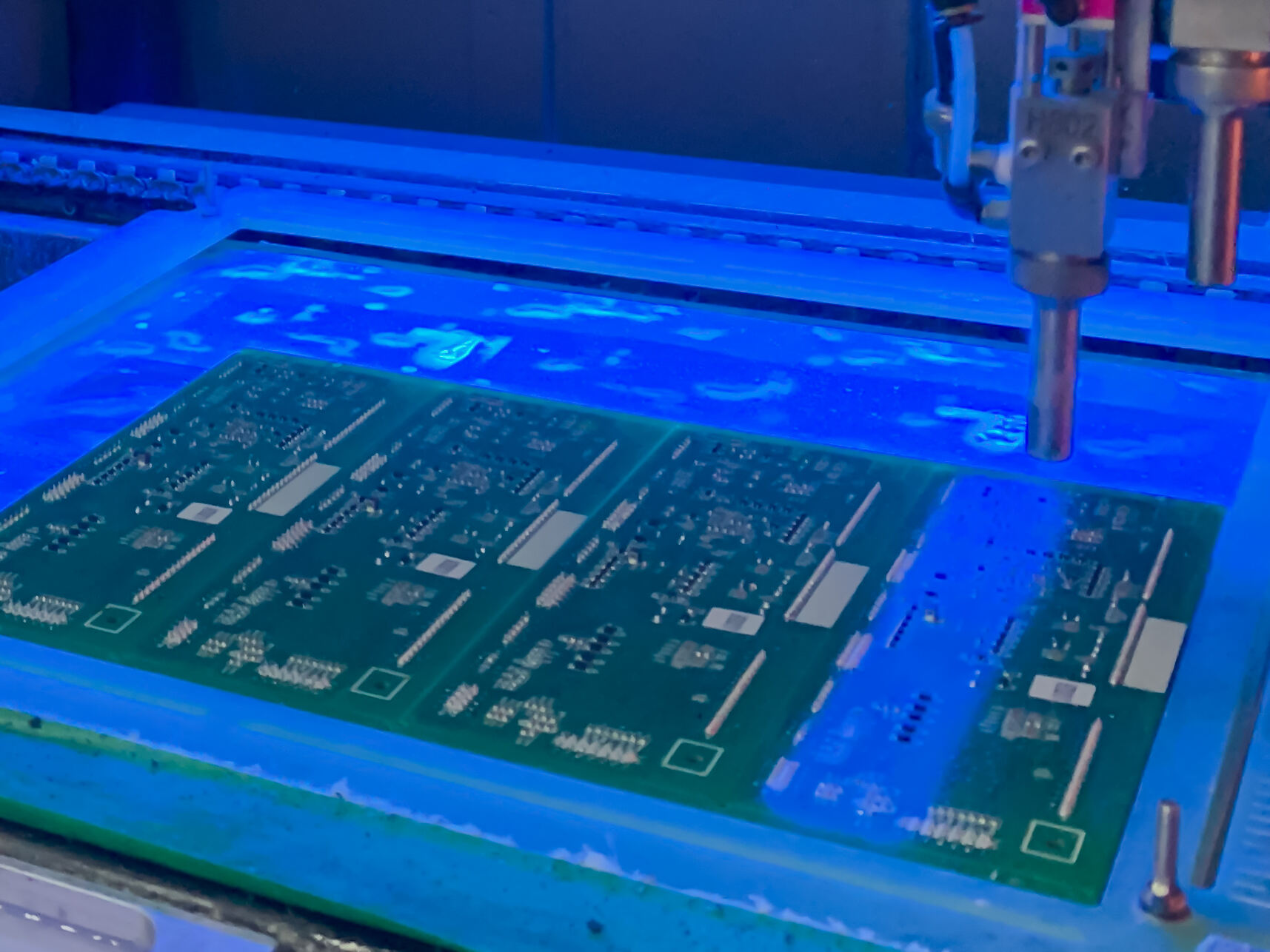

pcb assembly services

PCB assembly services represent a comprehensive solution for transforming bare printed circuit boards into fully functional electronic components. This sophisticated process encompasses component placement, soldering, and quality assurance, utilizing state-of-the-art surface mount technology (SMT) and through-hole mounting techniques. Modern PCB assembly services employ advanced automation systems and precision equipment to ensure accurate component placement, reliable connections, and consistent quality across production runs. The service typically includes careful component procurement, automated optical inspection (AOI), functional testing, and thorough quality control measures. These services cater to diverse industries, from consumer electronics to aerospace, offering scalable solutions for both prototype and high-volume production needs. Advanced PCB assembly facilities maintain strict adherence to international manufacturing standards and utilize environmentally conscious processes. The service providers often offer design for manufacturability (DFM) analysis, helping clients optimize their designs for efficient production and enhanced reliability. This comprehensive approach ensures that the final assembled PCBs meet exact specifications and performance requirements while maintaining cost-effectiveness and rapid turnaround times.