box build assembly

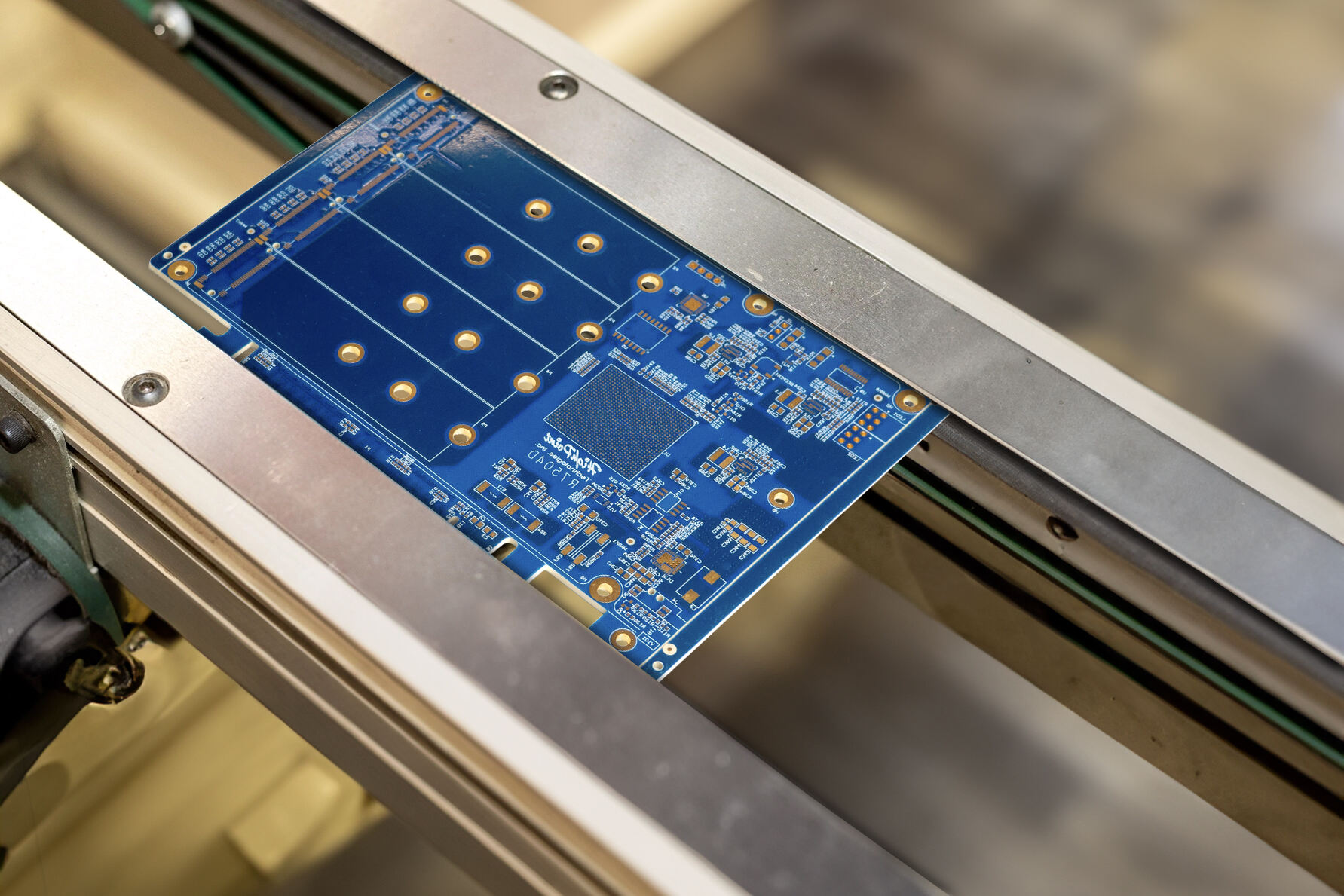

Box build assembly represents a comprehensive manufacturing service that transforms individual electronic components into fully functional, ready-to-use systems. This sophisticated process encompasses the complete assembly of electronic products, from PCB integration to final packaging. The service includes component sourcing, PCB assembly, wire harness installation, chassis assembly, and comprehensive testing protocols. Modern box build assembly facilities utilize advanced automation technologies alongside skilled manual assembly techniques to ensure optimal quality and efficiency. The process typically begins with careful component procurement and verification, followed by systematic assembly procedures that adhere to strict quality control standards. These facilities employ state-of-the-art testing equipment to verify electrical integrity, functional performance, and overall product reliability. The versatility of box build assembly makes it suitable for various industries, including telecommunications, medical devices, industrial automation, and consumer electronics. The service can accommodate both low-volume, high-complexity projects and high-volume production runs, offering scalability to meet diverse manufacturing needs. Environmental controls and electrostatic discharge (ESD) protection measures are implemented throughout the assembly process to protect sensitive components.