quick turn pcb boards

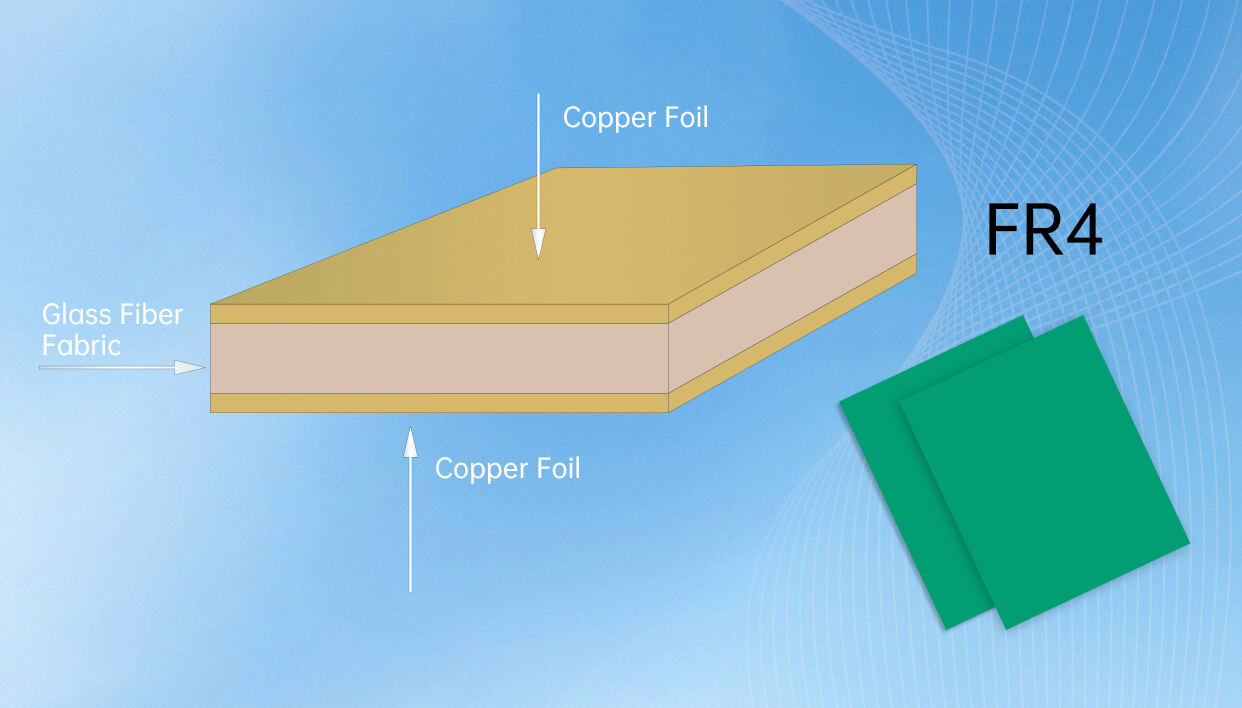

Quick turn PCB boards represent a cutting-edge solution in the electronics manufacturing industry, offering rapid prototyping and production capabilities for printed circuit boards. These specialized boards are designed to meet urgent project demands while maintaining high quality and precision. The manufacturing process utilizes advanced technology and automated systems to expedite production without compromising reliability. Quick turn PCB boards feature sophisticated multi-layer configurations, ranging from simple 2-layer designs to complex 16-layer architectures, accommodating various electronic applications. The boards undergo rigorous quality control measures, including automated optical inspection and electrical testing, ensuring optimal performance. They support diverse surface finish options, including HASL, ENIG, and immersion silver, catering to different environmental and performance requirements. These boards find applications across multiple industries, from consumer electronics and telecommunications to aerospace and medical devices. The manufacturing process incorporates precise impedance control, advanced via technology, and sophisticated trace routing capabilities, making them suitable for both prototype development and small-batch production runs. Additionally, quick turn PCB boards can accommodate various substrate materials and thicknesses, offering flexibility in design and application.