prototype pcb assembly factory

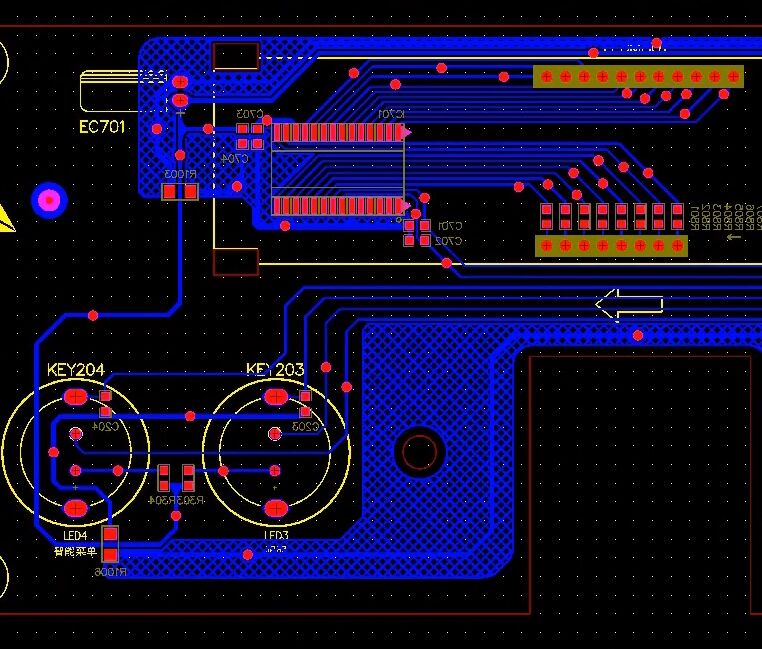

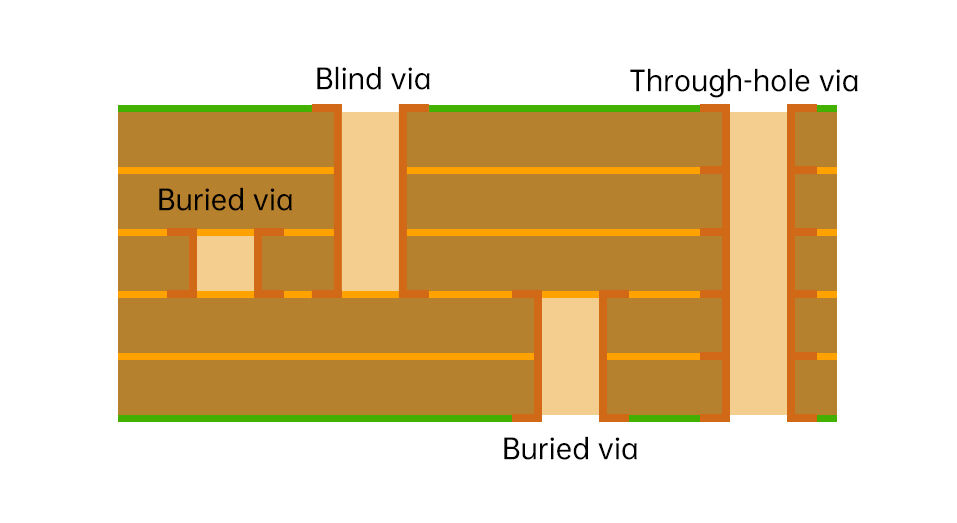

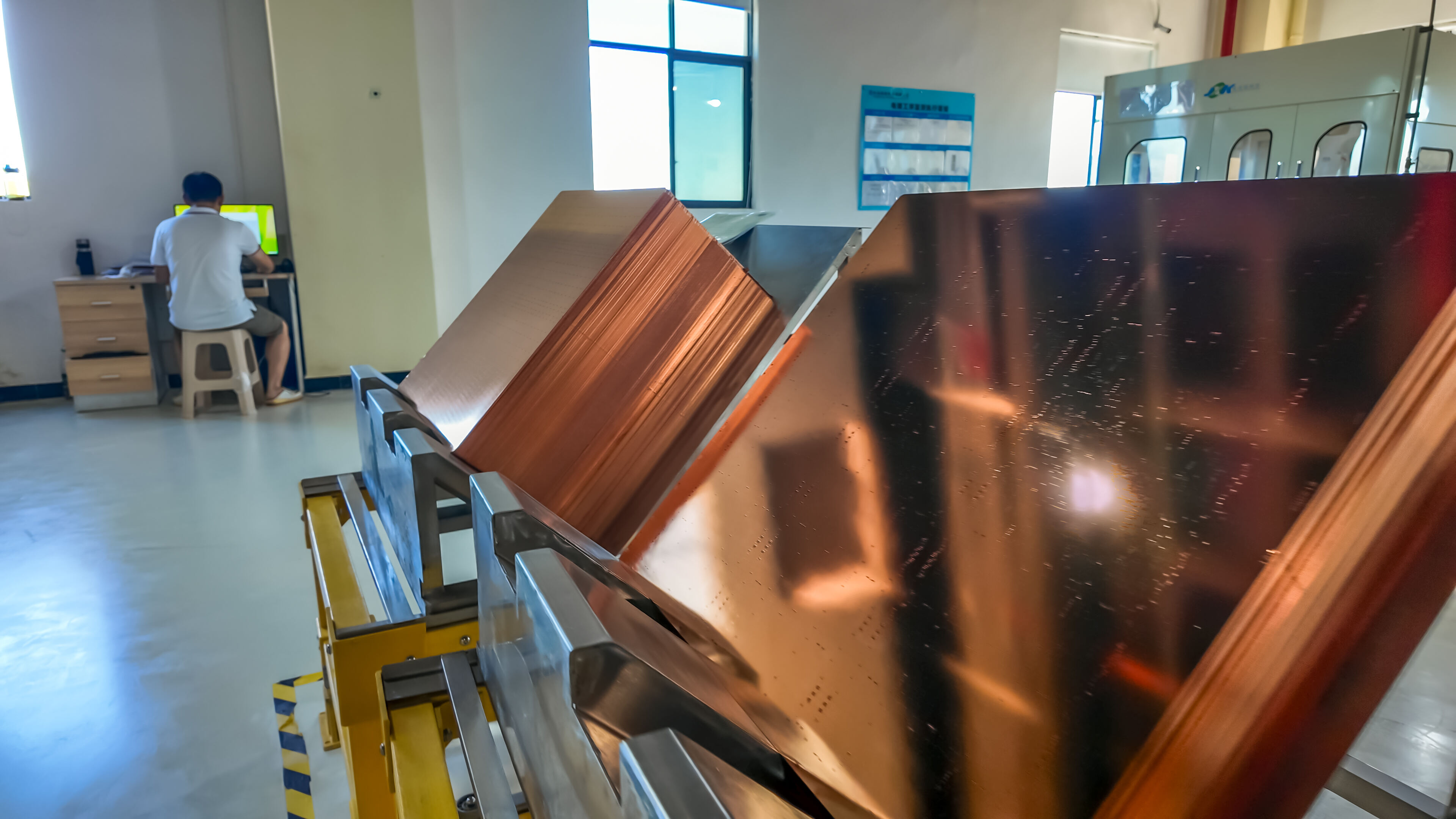

A prototype PCB assembly factory represents a cutting-edge manufacturing facility dedicated to producing high-quality printed circuit boards in small quantities for testing and validation purposes. These specialized facilities combine advanced automation with precise manual operations to create fully functional PCB assemblies. The factory typically features state-of-the-art surface mount technology (SMT) lines, automated optical inspection (AOI) systems, and specialized testing equipment. The facility's main functions include PCB fabrication, component placement, soldering, and comprehensive quality testing. The technology infrastructure encompasses advanced pick-and-place machines capable of handling components as small as 01005, reflow ovens with multiple heating zones for optimal soldering profiles, and sophisticated inspection systems that ensure assembly accuracy. The factory maintains a controlled environment with proper temperature, humidity, and electrostatic discharge (ESD) protection measures. Applications range from consumer electronics prototypes to aerospace and medical device testing units. The facility can accommodate various board sizes and complexities, from simple single-layer designs to complex multilayer boards with high-density interconnects. This versatility makes it ideal for research and development teams, startups, and established manufacturers requiring quick turnaround times for prototype validation.