best pcb manufacturers

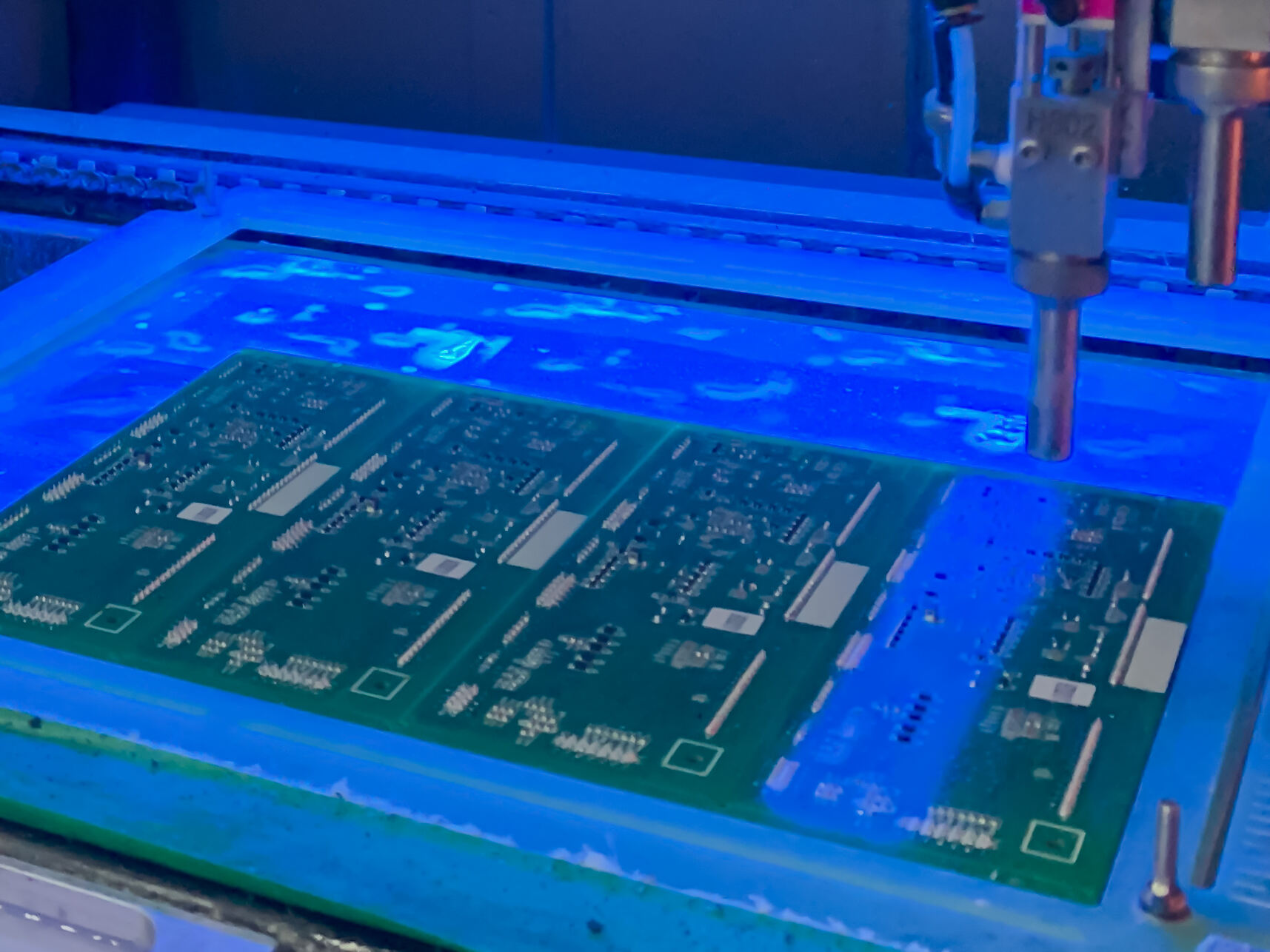

The best PCB manufacturers represent the pinnacle of electronic circuit board production, combining cutting-edge technology with precision engineering. These industry leaders utilize state-of-the-art equipment and automated processes to produce high-quality printed circuit boards that meet rigorous international standards. Their facilities incorporate advanced manufacturing capabilities, including multi-layer board production, flex and rigid-flex PCB manufacturing, and high-density interconnect (HDI) technology. Leading PCB manufacturers maintain strict quality control measures throughout the production process, from initial design verification to final testing. They employ sophisticated computer-aided design (CAD) systems and automated optical inspection (AOI) equipment to ensure precise component placement and error-free assembly. These manufacturers typically offer comprehensive services, including prototype development, mass production, and specialized solutions for various industries such as aerospace, telecommunications, automotive, and medical devices. Their expertise extends to handling complex specifications, including fine-pitch components, impedance control, and advanced surface finish options. Modern PCB manufacturers also emphasize environmental responsibility by implementing green manufacturing processes and complying with international environmental regulations.