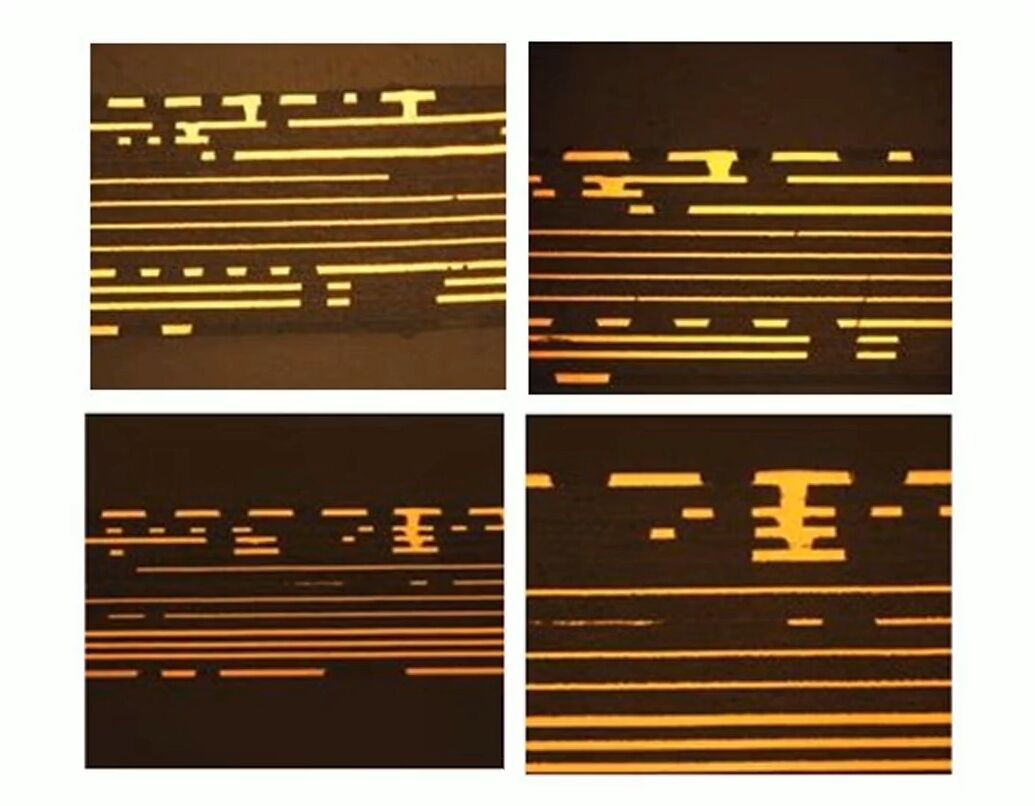

annular ring pcb

An annular ring PCB refers to the copper area surrounding a drilled hole on a printed circuit board, serving as a crucial element in PCB manufacturing and reliability. This conductive ring ensures proper electrical connection between the hole and the copper layer while providing mechanical stability. The annular ring consists of two main components: the outer diameter of the copper pad and the inner diameter of the drilled hole. The difference between these measurements creates the actual ring width, which is critical for maintaining signal integrity and structural strength. In modern PCB design, annular rings play a vital role in both through-hole and via connections, helping to prevent delamination and ensuring reliable plating during the manufacturing process. The technology behind annular ring PCBs has evolved significantly, with current standards requiring precise measurements and tolerances to meet increasingly demanding electronic applications. These rings are particularly important in multilayer PCBs, where they help maintain proper layer-to-layer connections and prevent potential manufacturing defects. The implementation of annular rings requires careful consideration of design rules and manufacturing capabilities, as insufficient ring width can lead to connection failures and reduced board reliability.