heavy copper pcb manufacturers

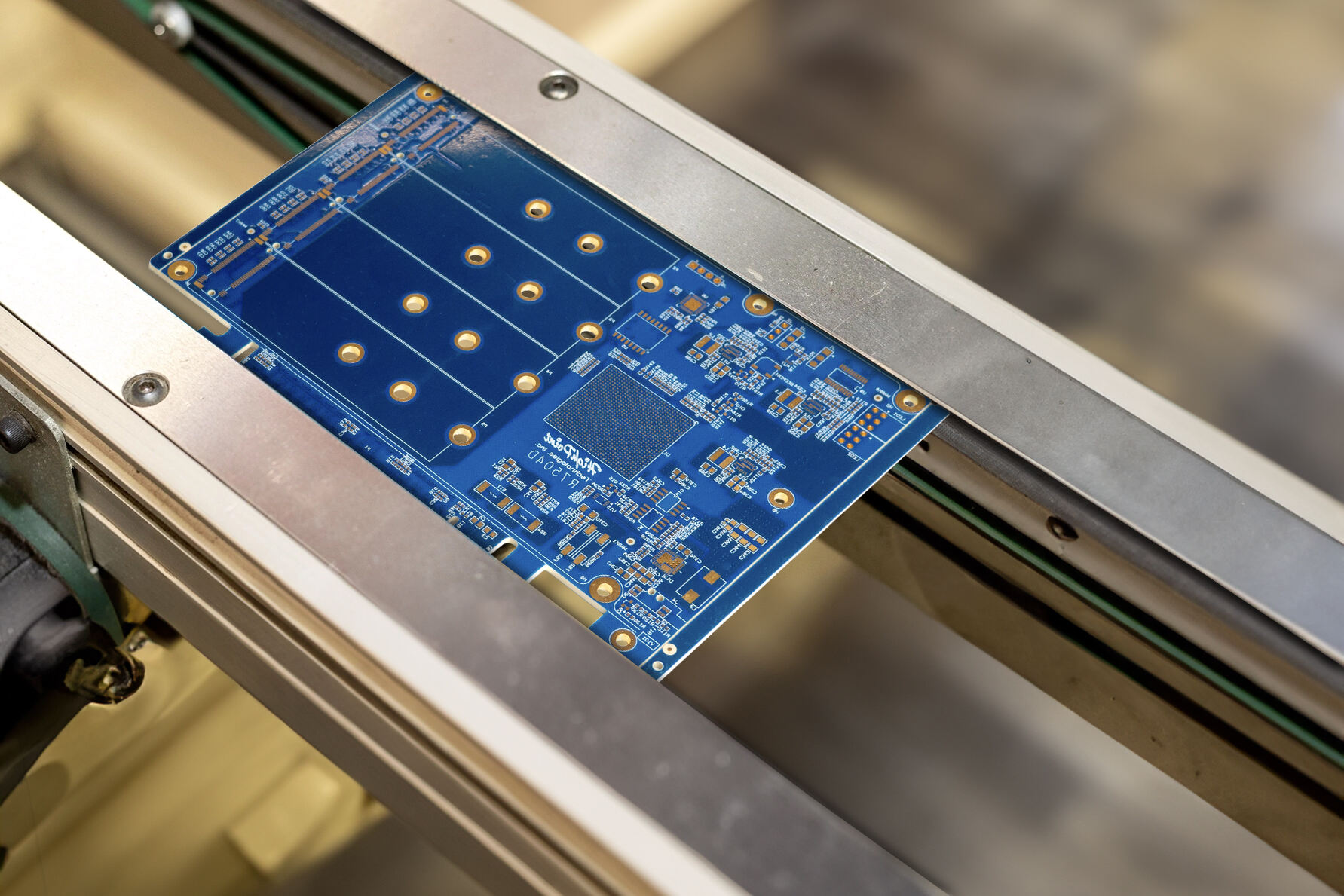

Heavy copper PCB manufacturers specialize in producing circuit boards with copper thickness exceeding standard specifications, typically ranging from 3oz to over 20oz. These manufacturers employ advanced manufacturing processes and specialized equipment to create robust circuit boards capable of handling high current loads and thermal demands. Their facilities integrate cutting-edge plating technologies, precise etching systems, and stringent quality control measures to ensure consistent production of high-performance PCBs. These manufacturers utilize sophisticated design software and simulation tools to optimize copper distribution and thermal management. They maintain strict adherence to international manufacturing standards while offering customization options for specific applications. The production process involves multiple stages, including advanced copper plating, precise pattern etching, and comprehensive testing procedures. These manufacturers typically serve industries requiring high-power applications, such as power electronics, automotive systems, LED lighting, and industrial equipment. Their capabilities extend to producing multilayer boards with varying copper weights on different layers, allowing for optimal design flexibility and performance optimization.