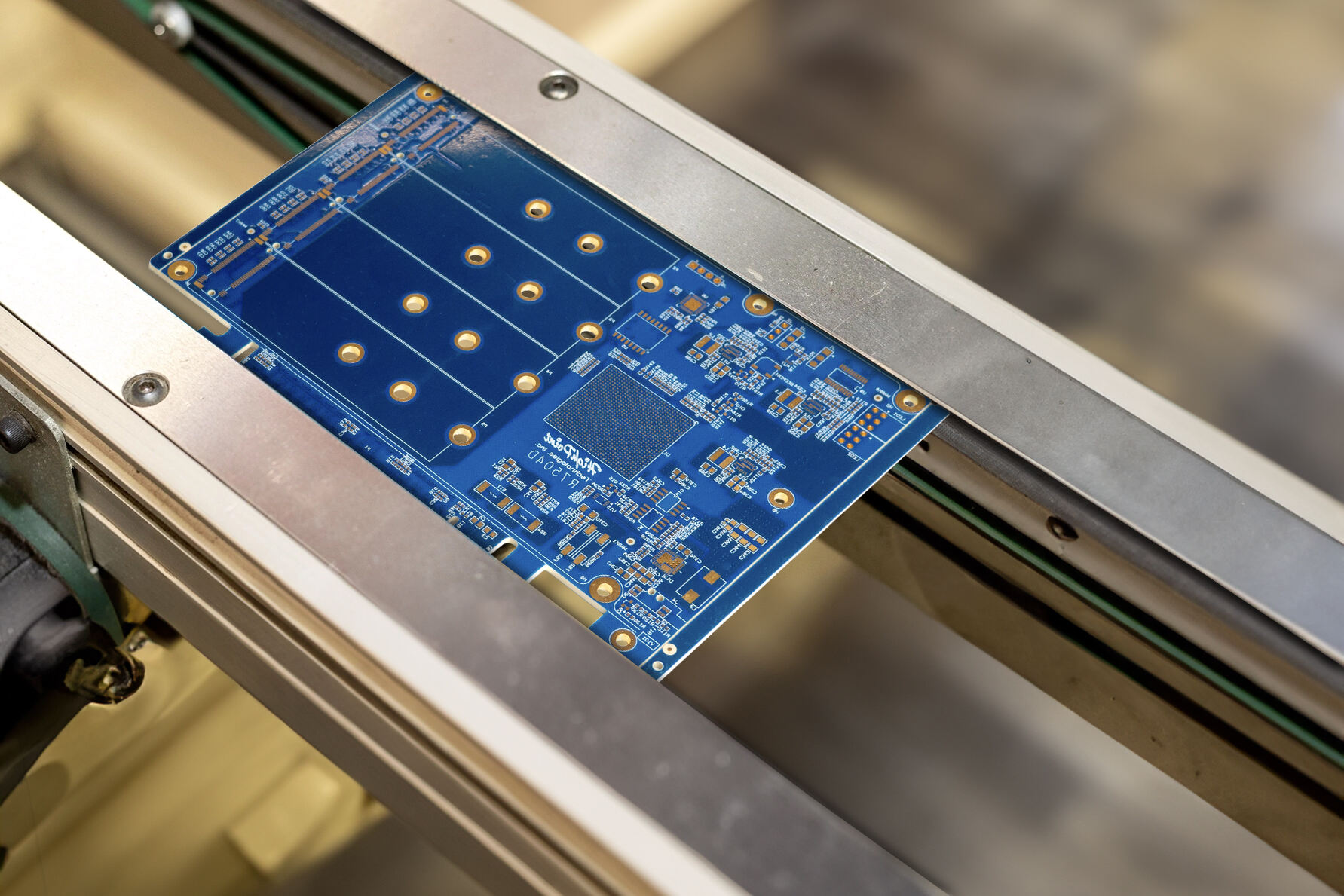

double sided pcb manufacturer

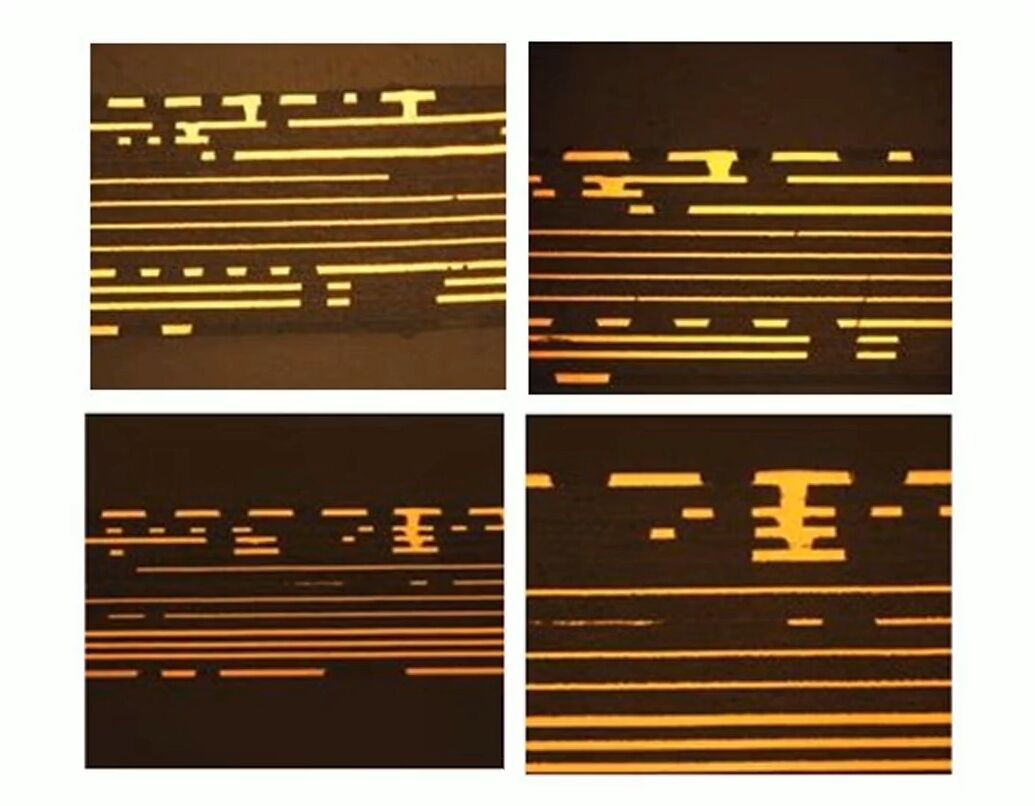

A double sided PCB manufacturer specializes in producing circuit boards with conductive patterns on both sides, enabling more complex electronic designs in a compact form factor. These manufacturers employ advanced manufacturing processes including photolithography, plating, and through-hole technology to create reliable interconnections between both sides of the board. They utilize state-of-the-art equipment for precise drilling, copper deposition, and quality testing to ensure consistent product quality. Modern double sided PCB manufacturers typically offer comprehensive services from design consultation to final testing, incorporating automated optical inspection systems and electrical testing protocols. They maintain strict quality control measures, following international standards such as IPC and ISO requirements. These facilities often feature clean room environments for handling sensitive components and specialized equipment for surface mount technology (SMT) and through-hole component assembly. The manufacturers capabilities extend to various substrate materials, including FR-4, high-frequency materials, and flexible substrates, accommodating diverse application requirements from consumer electronics to industrial control systems.