Understanding the Foundation of Modern Electronics Manufacturing

In the ever-evolving world of electronics manufacturing, two critical components stand at the heart of nearly every electronic device we use today: PCB and PCBA. These terms are often used interchangeably, yet they represent distinct stages in the electronic manufacturing process. The distinction between PCB and PCBA differences is fundamental to understanding how our electronic devices are brought to life, from simple calculators to complex smartphones.

The electronics industry relies heavily on both PCBs (Printed Circuit Boards) and PCBAs (Printed Circuit Board Assemblies) to create the sophisticated devices that power our modern world. By understanding these components, we can better appreciate the intricate process of electronics manufacturing and make more informed decisions in product development and manufacturing.

The Fundamentals of PCB Technology

Core Components of a PCB

A Printed Circuit Board (PCB) serves as the foundation for electronic components, essentially acting as a blank canvas for electronic design. At its most basic level, a PCB consists of several layers of material, each serving a specific purpose. The base material, typically made from fiberglass, provides structural support and electrical insulation. This is followed by copper layers that create conductive pathways for electrical signals to travel between components.

Modern PCBs often incorporate multiple layers, allowing for more complex circuit designs in a compact space. The surface of a PCB features various markings, including solder masks that protect the copper traces and silkscreen labels that aid in component placement and identification during assembly.

PCB Manufacturing Process

The manufacturing process of PCBs involves several sophisticated steps, beginning with design software where engineers create detailed schematics and board layouts. These designs are then translated into physical boards through a series of chemical and mechanical processes. The copper layers are etched to create the necessary circuit patterns, while holes are drilled to accommodate component leads and create connections between layers.

Quality control is crucial during PCB manufacturing, as even minor defects can render the board unusable. Manufacturers employ various testing methods, including optical inspection and electrical connectivity tests, to ensure each board meets specifications before moving to the assembly phase.

PCBA: The Evolution from Board to Functional Circuit

The Assembly Process

PCBA represents the next stage in electronic manufacturing, where components are mounted onto the bare PCB. This process transforms a simple circuit board into a functional electronic assembly. The assembly process typically involves both automated and manual steps, depending on the complexity of the design and the types of components being used.

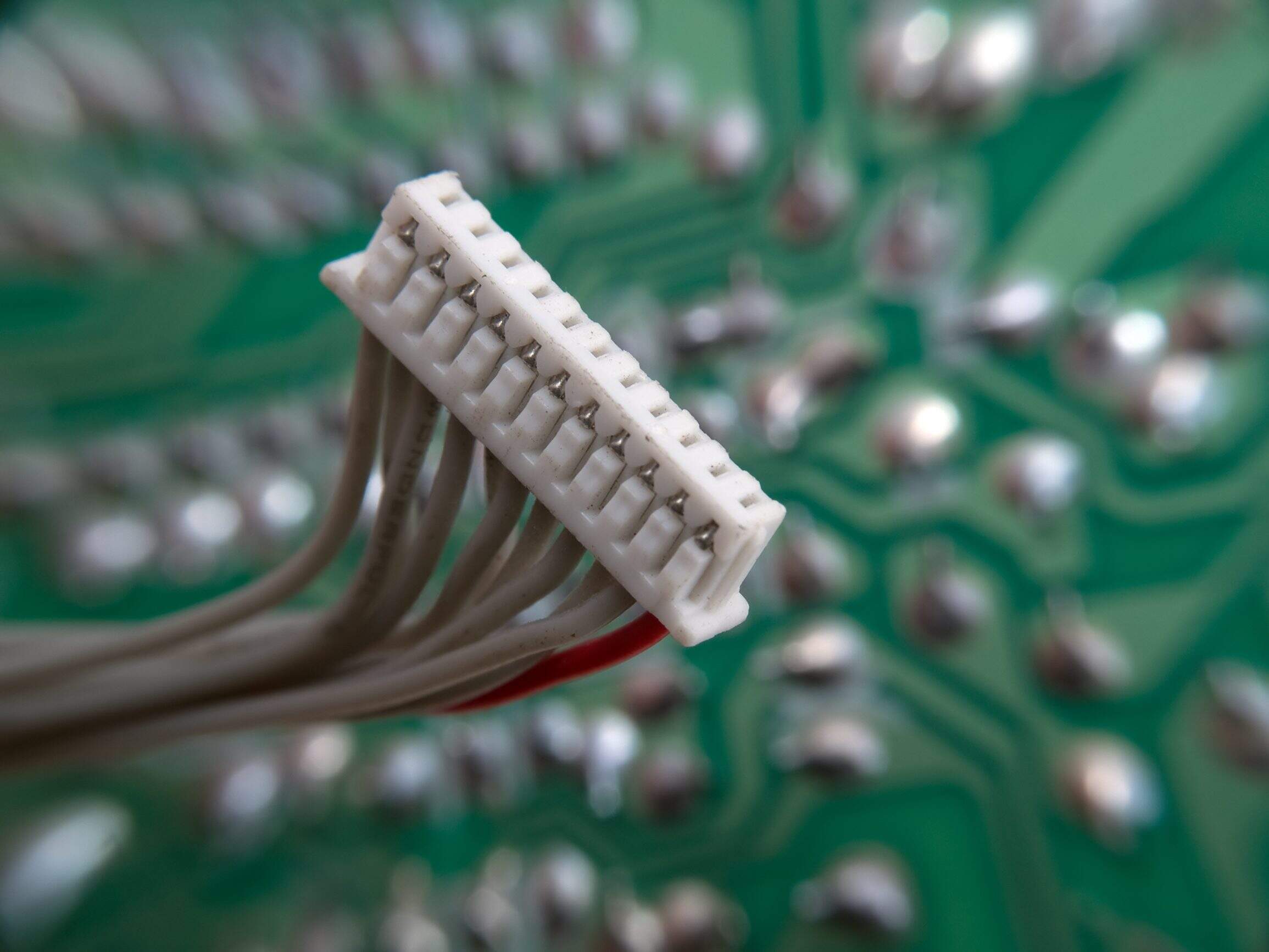

Surface-mount technology (SMT) and through-hole mounting are the two primary methods used in PCBA. SMT involves placing components directly onto the surface of the board, while through-hole mounting requires components to be inserted through pre-drilled holes. Many modern assemblies utilize both techniques to achieve optimal functionality and durability.

Component Integration and Testing

The success of a PCBA depends heavily on proper component placement and soldering. Automated pick-and-place machines precisely position surface-mount components, while specialized soldering equipment creates reliable electrical connections. After assembly, each PCBA undergoes rigorous testing to verify functionality and identify any potential issues.

Testing procedures may include in-circuit testing, functional testing, and environmental stress screening to ensure the assembly can withstand its intended operating conditions. This comprehensive approach to quality assurance helps minimize field failures and maximize product reliability.

Key Distinctions in Manufacturing and Application

Production Timeline and Complexity

One of the fundamental PCB and PCBA differences lies in their manufacturing timelines and complexity. PCB production focuses on creating the bare board with its conductive pathways and protective layers, typically requiring less time than the complete assembly process. PCBA manufacturing involves additional steps, including component procurement, placement, soldering, and testing, resulting in longer production cycles.

The complexity of modern electronic devices often necessitates careful balance between PCB design and assembly requirements. Manufacturers must consider factors such as component availability, assembly equipment capabilities, and quality control measures when planning production schedules.

Cost Considerations and Value Chain

The cost structure for PCBs and PCBAs differs significantly due to their respective positions in the value chain. PCB costs primarily relate to materials and manufacturing processes, while PCBA expenses include additional components, assembly labor, and testing procedures. Understanding these cost differences is crucial for effective project budgeting and pricing strategies.

Investment in advanced manufacturing equipment and quality control systems often leads to higher initial costs but can result in long-term savings through improved efficiency and reduced defect rates. This balance between cost and quality continues to drive innovation in both PCB and PCBA manufacturing.

Industry Applications and Future Trends

Current Market Demands

The electronics industry continues to push the boundaries of what's possible with PCB and PCBA technology. Miniaturization trends drive the development of increasingly complex multilayer boards and more sophisticated assembly techniques. The demand for smaller, more powerful devices influences both PCB design parameters and PCBA manufacturing capabilities.

Different sectors, from consumer electronics to aerospace, require varying levels of complexity and reliability in their PCB and PCBA specifications. This diversity drives continuous improvement in manufacturing processes and quality control methods.

Emerging Technologies and Innovations

The future of PCB and PCBA manufacturing is being shaped by emerging technologies such as artificial intelligence, advanced materials, and automated quality control systems. These innovations promise to further streamline production processes while improving reliability and reducing costs. Additionally, environmental considerations are driving the development of more sustainable manufacturing methods and materials.

As electronic devices become more integrated into our daily lives, the distinction between PCB and PCBA differences will continue to evolve, with new manufacturing techniques and materials emerging to meet changing market demands.

Frequently Asked Questions

What are the primary advantages of PCBA over bare PCBs?

PCBAs offer complete functionality as they include all necessary electronic components, making them ready for immediate integration into devices. They represent a finished product rather than just the foundation, saving time and resources in the final product assembly process.

How does the testing process differ between PCBs and PCBAs?

PCB testing primarily focuses on structural integrity and conductor pathway continuity, while PCBA testing is more comprehensive, including functional testing of all assembled components, signal integrity, and overall circuit performance verification.

Can a PCB be modified after manufacturing, while a PCBA cannot?

While PCBs can sometimes be modified through additional drilling or copper trace modification, PCBAs are generally more difficult to modify due to the presence of soldered components. Any significant changes typically require a new assembly process.

What factors influence the choice between different PCB and PCBA manufacturing methods?

The choice depends on various factors including production volume, component types, required reliability levels, cost constraints, and end-product application. Environmental conditions, regulatory requirements, and time-to-market considerations also play crucial roles in the decision-making process.