Understanding the Foundation of Modern Electronics

In the heart of every electronic device lies a PCB circuit board, a remarkable feat of engineering that revolutionized the electronics industry. These thin, layered platforms serve as the backbone for connecting electronic components, enabling the functionality we rely on daily in our smartphones, computers, household appliances, and countless other devices. As technology continues to advance, PCB circuit boards have evolved from simple single-layer designs to complex multi-layer systems that power the most sophisticated electronic equipment.

The evolution of PCB circuit boards represents one of the most significant advances in electronics manufacturing, transforming the way we design, produce, and use electronic devices. From their humble beginnings as basic wire-wrapped circuits to today's high-density interconnect boards, PCBs have become increasingly sophisticated while maintaining their fundamental role as the essential foundation of electronic systems.

Essential Components and Structure of PCB Circuit Boards

Base Materials and Layers

At its core, a PCB circuit board consists of several layers of different materials carefully assembled to create a reliable platform for electronic components. The foundation is typically made from FR4, a flame-resistant fiberglass-reinforced epoxy laminate material. This substrate provides the necessary structural integrity and electrical insulation properties required for proper circuit function.

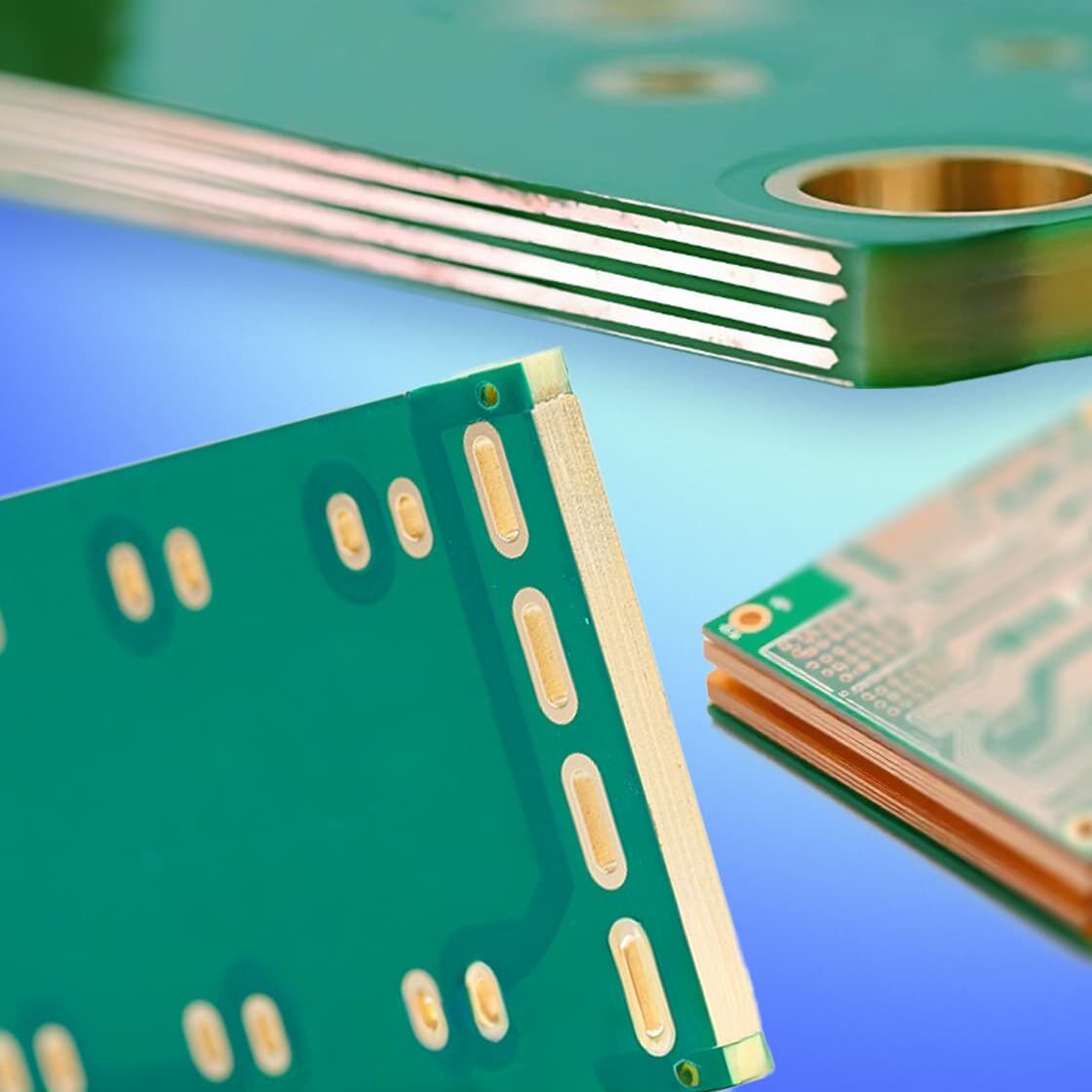

The copper layer, which is bonded to the substrate, forms the conductive pathways that allow electrical signals to flow between components. Modern PCB circuit boards can feature multiple copper layers, each separated by insulating material, enabling more complex circuit designs while maintaining a compact form factor. The outermost layer usually includes a solder mask, which protects the copper traces and prevents unwanted connections during assembly.

Conducting Paths and Traces

The intricate network of copper traces on a PCB circuit board serves as the nervous system of the electronic device. These pathways are precisely designed to carry different types of signals, from power distribution to high-speed data transmission. The width and spacing of traces are carefully calculated to ensure proper current handling capacity and signal integrity.

Modern PCB designs often incorporate ground planes and power planes, which are entire layers dedicated to providing stable power distribution and signal return paths. This sophisticated arrangement helps minimize electromagnetic interference and ensures reliable operation of the circuit board under various conditions.

Design Process and Manufacturing Techniques

Computer-Aided Design Tools

The creation of a PCB circuit board begins with sophisticated computer-aided design (CAD) software. These powerful tools allow engineers to create detailed schematics, place components, and route traces with precision. Modern PCB design software includes advanced features such as auto-routing capabilities, design rule checking, and 3D visualization tools that help optimize the layout before manufacturing.

Engineers must consider various factors during the design phase, including component placement, signal integrity, thermal management, and manufacturing constraints. The software helps validate these aspects through simulation and analysis tools, reducing the likelihood of errors in the final product.

Manufacturing Steps and Quality Control

The manufacturing process of a PCB circuit board involves multiple precise steps, beginning with the creation of the copper pattern through photolithography. This process transfers the design onto the copper-clad board using light-sensitive chemicals. Subsequently, excess copper is etched away, leaving only the desired circuit patterns.

Quality control measures are implemented throughout the manufacturing process, including optical inspection, electrical testing, and environmental stress testing. These steps ensure that each PCB circuit board meets the specified requirements for functionality and reliability. Advanced manufacturing facilities employ automated inspection systems that can detect even microscopic defects in the board's construction.

Applications and Future Developments

Current Industry Applications

PCB circuit boards are fundamental components in virtually every electronic device and system. In consumer electronics, they enable the functionality of smartphones, tablets, and laptops. In industrial applications, they control manufacturing equipment and process automation systems. The automotive industry relies heavily on PCB circuit boards for everything from engine management to advanced driver assistance systems.

The medical field utilizes specialized PCB circuit boards in diagnostic equipment, patient monitoring systems, and implantable devices. These applications demand the highest levels of reliability and precision, showcasing the versatility and importance of PCB technology in critical applications.

Emerging Technologies and Innovations

The future of PCB circuit board technology is evolving rapidly with new materials and manufacturing techniques. Flexible and rigid-flex PCBs are gaining popularity, allowing for more creative form factors and improved durability. Additionally, the development of high-frequency materials enables PCBs to support increasingly faster data transmission rates required for 5G and beyond.

Advancements in miniaturization continue to push the boundaries of PCB design, with components and traces becoming increasingly smaller while maintaining or improving performance. The integration of embedded components and 3D printing technologies promises to revolutionize how PCB circuit boards are manufactured and utilized in next-generation electronic devices.

Frequently Asked Questions

How long does a PCB circuit board typically last?

The lifespan of a PCB circuit board varies depending on several factors, including usage conditions, environmental factors, and quality of materials used. Under normal operating conditions, a well-designed and properly manufactured PCB can last 20 years or more. However, frequent exposure to extreme temperatures, humidity, or mechanical stress can significantly reduce its lifespan.

Can damaged PCB circuit boards be repaired?

Yes, many types of PCB circuit board damage can be repaired by skilled technicians. Common repairs include replacing damaged components, repairing broken traces, and resoldering loose connections. However, extensive damage to the board substrate or complex multilayer issues may make repair impractical or more expensive than replacement.

What makes a PCB circuit board design considered high quality?

A high-quality PCB circuit board design incorporates several key elements: proper component spacing for thermal management, appropriate trace widths for current handling, sufficient clearance between signals to prevent interference, robust power distribution, and comprehensive design rule checking. Additionally, the design should account for manufacturing tolerances and include test points for quality assurance.