Selecting the right supplier for your electronics manufacturing needs requires careful consideration of multiple technical and business factors. The PCB printed circuit board industry has evolved significantly, with modern suppliers offering advanced capabilities that extend far beyond basic fabrication services. Understanding the key criteria for supplier evaluation can mean the difference between project success and costly delays or quality issues.

The complexity of modern electronic devices demands suppliers who can handle sophisticated multilayer designs, high-frequency applications, and stringent quality requirements. Whether you're developing consumer electronics, automotive systems, or industrial control equipment, your supplier choice directly impacts product performance, time-to-market, and overall project profitability. This comprehensive evaluation process requires understanding both technical capabilities and business practices that separate exceptional suppliers from mediocre ones.

Technical Capabilities Assessment

Manufacturing Technology and Equipment

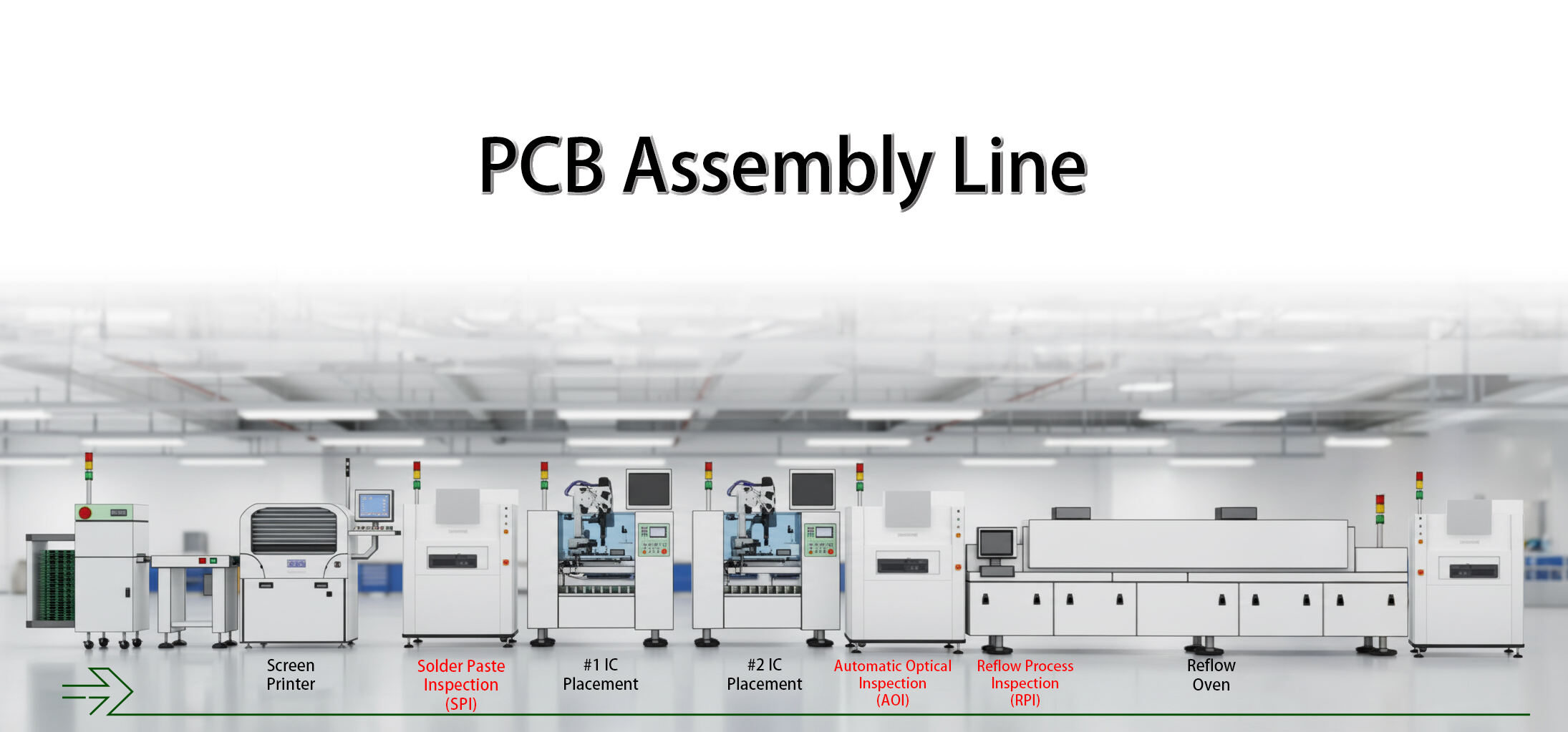

Advanced manufacturing capabilities form the foundation of any reliable PCB supplier relationship. Modern facilities should feature state-of-the-art equipment including high-precision drilling machines, automated optical inspection systems, and advanced plating technologies. The supplier's ability to handle various substrate materials, from standard FR-4 to exotic high-frequency materials like Rogers or Teflon, indicates their technical sophistication and market positioning.

Equipment age and maintenance programs significantly impact production quality and delivery reliability. Suppliers investing in recent technology upgrades demonstrate commitment to staying competitive and meeting evolving industry standards. Ask potential suppliers about their equipment refresh cycles, preventive maintenance schedules, and backup capacity planning to ensure consistent production capabilities.

The integration of Industry 4.0 technologies, including IoT sensors, real-time monitoring systems, and predictive maintenance algorithms, represents the cutting edge of PCB manufacturing. Suppliers embracing these technologies typically offer better traceability, faster problem resolution, and more accurate delivery predictions throughout the production process.

Design and Engineering Support

Comprehensive design for manufacturing (DFM) support distinguishes professional suppliers from basic fabrication shops. Experienced engineering teams should provide detailed feedback on design optimization opportunities, potential manufacturing challenges, and cost reduction strategies. This collaboration often results in improved product performance, enhanced reliability, and reduced overall project costs.

The supplier's CAD software compatibility and file format support directly impacts design iteration speed and accuracy. Modern suppliers should handle industry-standard formats including Gerber, Excellon, and ODB++, while offering direct integration with popular design tools like Altium Designer, KiCad, and Eagle. Seamless data exchange reduces errors and accelerates the prototype-to-production transition.

Signal integrity analysis capabilities become increasingly important for high-speed digital designs and RF applications. Suppliers offering electromagnetic simulation services, impedance modeling, and crosstalk analysis provide valuable support for complex designs where electrical performance is critical. This expertise helps identify and resolve potential issues before production begins.

Quality Management Systems

Certification Standards and Compliance

Industry certifications provide objective evidence of a supplier's commitment to quality and process control. ISO 9001 certification represents basic quality management system requirements, while ISO 14001 demonstrates environmental management capabilities. For automotive applications, IATF 16949 certification is typically mandatory, and aerospace projects often require AS9100 compliance.

Medical device manufacturers should prioritize suppliers with ISO 13485 certification, which specifically addresses medical device quality management requirements. Military and defense applications may require additional certifications such as IPC-6012 Class 3 or MIL-STD compliance, depending on specific application requirements and performance criteria.

Regular third-party audits and certification maintenance demonstrate ongoing commitment to quality improvement. Suppliers should provide current certification documentation and audit schedules, along with corrective action records showing how they address any identified deficiencies or improvement opportunities.

Testing and Inspection Procedures

Comprehensive testing protocols ensure consistent product quality and reliability throughout production runs. Electrical testing should include continuity verification, insulation resistance measurement, and impedance validation for controlled impedance designs. Advanced suppliers may offer additional testing services such as thermal cycling, vibration testing, and accelerated aging studies.

Automated optical inspection (AOI) systems provide detailed visual verification of PCB printed circuit features, including trace width accuracy, via formation quality, and solder mask alignment. High-resolution inspection capabilities can detect defects invisible to manual inspection, significantly improving overall quality levels and reducing field failure rates.

Statistical process control (SPC) implementation allows suppliers to monitor process variations and identify trends before they impact product quality. Suppliers should provide process capability studies, control charts, and quality metrics demonstrating their ability to maintain consistent production standards over time.

Supply Chain Management

Capacity Planning and Scalability

Production capacity planning directly impacts delivery reliability and cost competitiveness. Suppliers should provide transparent information about their current capacity utilization, expansion plans, and ability to handle volume fluctuations. Understanding their customer base diversity helps assess potential capacity conflicts during peak demand periods.

Scalability considerations become critical for products transitioning from prototype to high-volume production. Suppliers should demonstrate experience managing volume ramp-ups, including process optimization, yield improvement initiatives, and supply chain adjustments required for increased production levels. This experience directly correlates with successful product launch execution.

Geographic distribution and multiple facility capabilities provide risk mitigation and logistics advantages. Suppliers with strategically located production facilities can offer reduced shipping costs, shorter lead times, and business continuity protection against regional disruptions or natural disasters.

Material Sourcing and Inventory Management

Reliable material sourcing practices ensure consistent availability of required substrates, copper foils, and specialty materials. Suppliers should maintain relationships with multiple material vendors to avoid single-source dependencies that could impact delivery schedules. Their inventory management practices should balance carrying costs with material availability requirements.

Traceability systems enable rapid identification and containment of material-related quality issues. Comprehensive lot tracking from incoming materials through finished goods provides essential information for quality investigations and regulatory compliance requirements. This capability becomes particularly important for automotive, medical, and aerospace applications.

Forward-looking material planning helps suppliers anticipate and prepare for material shortages or price fluctuations. Proactive suppliers maintain buffer stocks of critical materials and develop alternative sourcing strategies to minimize impact on customer delivery schedules during supply chain disruptions.

Communication and Project Management

Customer Service and Responsiveness

Effective communication forms the backbone of successful supplier relationships. Responsive customer service teams should provide regular project updates, proactive issue notification, and clear escalation procedures for addressing problems quickly. The supplier's communication style and frequency should align with your project management requirements and organizational culture.

Technical support availability becomes crucial during design development and problem-solving situations. Suppliers should offer direct access to engineering expertise, including applications engineers familiar with your specific industry requirements and technical challenges. This support depth often determines how quickly design issues can be resolved and production initiated.

Multi-language support and cultural understanding facilitate smooth collaboration for international projects. Suppliers serving global markets should demonstrate experience working across different time zones, regulatory environments, and business practices to ensure seamless project execution regardless of geographic complexity.

Project Tracking and Documentation

Real-time project visibility through online portals or tracking systems enables proactive project management and early problem identification. Modern suppliers should offer digital access to order status, production schedules, quality test results, and shipping information. This transparency builds confidence and enables better coordination with downstream manufacturing activities.

Comprehensive documentation packages support production transfer, regulatory submissions, and quality auditing requirements. Suppliers should provide detailed fabrication drawings, material certifications, test reports, and process documentation as standard deliverables. The quality and completeness of this documentation often reflects the supplier's overall attention to detail and professionalism.

Version control and change management procedures ensure design integrity throughout the production lifecycle. Suppliers should maintain detailed records of design changes, engineering change orders, and approval workflows to prevent confusion and ensure all stakeholders work with current information.

Cost Considerations and Value Analysis

Pricing Structure and Transparency

Understanding supplier pricing methodologies helps evaluate competitiveness and identify cost optimization opportunities. Transparent pricing should clearly separate material costs, processing charges, setup fees, and additional services. This breakdown enables meaningful cost comparisons and supports value engineering initiatives throughout the product development process.

Volume pricing structures and long-term agreements can provide significant cost advantages for high-volume products. Suppliers should offer clear volume break points and be willing to negotiate pricing based on projected volumes and contract duration. However, the lowest price option may not represent the best overall value when quality, delivery, and service factors are considered.

Total cost of ownership analysis should include factors beyond unit price, such as quality-related costs, expediting charges, inventory carrying costs, and potential revenue impact from delivery delays. A comprehensive PCB Printed Circuit supplier evaluation considers these hidden costs alongside quoted prices to identify the most economically advantageous partnership.

Value-Added Services

Additional services offered by suppliers can significantly impact overall project efficiency and cost-effectiveness. Assembly services, including surface mount technology (SMT) and through-hole component installation, provide single-source convenience and improved quality control. Testing services, such as in-circuit testing (ICT) and functional verification, add value by catching defects before shipment.

Supply chain management services, including component procurement and inventory management, can reduce administrative overhead and improve material availability. Suppliers offering these services often leverage their purchasing power to achieve better component pricing and availability than individual customers could obtain independently.

Engineering services such as design review, signal integrity analysis, and thermal modeling provide expertise that may not be available internally. These services can accelerate development timelines, improve design robustness, and reduce the risk of costly redesigns during production ramp-up phases.

FAQ

What certifications should I look for in a PCB supplier?

Essential certifications include ISO 9001 for quality management, and industry-specific certifications like IATF 16949 for automotive, AS9100 for aerospace, or ISO 13485 for medical devices. Additional certifications such as UL recognition, RoHS compliance, and REACH compliance may be required depending on your target markets and regulatory requirements.

How important is geographic location when selecting a supplier?

Geographic location impacts shipping costs, lead times, communication efficiency, and supply chain risk. Local suppliers offer advantages in communication, faster prototyping, and easier quality auditing, while offshore suppliers may provide cost advantages for high-volume production. The optimal choice depends on your specific requirements for cost, speed, and risk tolerance.

What should I expect during the supplier qualification process?

A thorough qualification process typically includes facility auditing, capability assessment, quality system review, and pilot production runs. Expect to evaluate technical capabilities, quality procedures, financial stability, and cultural compatibility. The process may take several weeks or months but is essential for establishing a reliable long-term partnership.

How can I assess a supplier's financial stability?

Financial stability assessment should include reviewing audited financial statements, credit ratings, bank references, and customer references. Look for consistent profitability, reasonable debt levels, and evidence of ongoing investment in equipment and capabilities. Financial instability can lead to quality compromises, delivery delays, or complete business interruption.