Selecting the right PCB Circuit Board is crucial for ensuring the reliability and performance of electronic devices. Whether you're developing consumer electronics, industrial equipment, or advanced telecommunications systems, the quality of your PCB Circuit Board directly impacts product functionality, durability, and manufacturing costs. Understanding the key factors that distinguish high-quality boards from inferior alternatives can save significant time, money, and potential product failures in the long run.

Understanding PCB Circuit Board Materials and Construction

Substrate Material Selection

The foundation of any high-quality PCB Circuit Board lies in its substrate material. FR-4 remains the most widely used substrate due to its excellent electrical insulation properties, mechanical strength, and cost-effectiveness. However, specialized applications may require advanced materials like Rogers, Teflon, or ceramic substrates for enhanced performance characteristics. When evaluating substrate quality, examine the glass transition temperature (Tg), dielectric constant, and thermal expansion coefficients to ensure compatibility with your specific application requirements.

High-frequency applications demand substrates with low dielectric loss and stable electrical properties across temperature variations. The substrate thickness tolerance should typically remain within ±10% for standard applications, though precision electronics may require tighter specifications. Quality manufacturers provide detailed material certifications and test reports that verify substrate properties meet industry standards such as IPC-4101 specifications.

Copper Layer Quality and Thickness

Copper layer quality significantly affects signal integrity, current-carrying capacity, and overall board reliability. Premium PCB Circuit Board manufacturers use high-purity electrolytic copper with consistent thickness across the entire board surface. Standard copper weights range from 0.5 oz to 3 oz per square foot, with heavier copper layers available for high-current applications. Uniform copper distribution ensures consistent impedance control and minimizes signal loss in high-speed designs.

Examine copper adhesion strength through peel tests, which should meet or exceed IPC-6012 requirements. Poor copper adhesion can lead to delamination during thermal cycling or mechanical stress, resulting in circuit failures. Quality boards also feature smooth copper surfaces with minimal roughness variations, contributing to better signal propagation and reduced insertion loss in high-frequency applications.

Manufacturing Process Quality Indicators

Drilling Precision and Via Quality

Precision drilling capabilities distinguish professional-grade PCB Circuit Board manufacturers from lower-tier suppliers. High-quality boards feature consistent hole sizes with tight tolerances, typically ±0.05mm for standard applications and ±0.025mm for precision requirements. Via aspect ratios should remain within manufacturable limits, generally not exceeding 10:1 for through-hole vias and 6:1 for blind or buried vias in standard processes.

Inspect via barrel quality through cross-sectional analysis, looking for uniform copper plating without voids, cracks, or excessive roughness. Quality manufacturers employ advanced drilling equipment with regular bit replacement schedules and automated inspection systems to maintain consistent hole quality. Poor drilling practices can create stress concentrations that lead to reliability issues during thermal cycling or mechanical shock conditions.

Solder Mask Application and Accuracy

Professional solder mask application requires precise registration, uniform thickness, and excellent adhesion to the underlying copper and substrate materials. Quality PCB Circuit Board manufacturing processes achieve solder mask registration accuracy within ±0.025mm, ensuring proper pad exposure and preventing bridging during assembly. The solder mask should exhibit consistent color uniformity and surface smoothness without pinholes, scratches, or contamination.

Evaluate solder mask adhesion through tape tests and thermal shock testing to verify long-term reliability. Premium boards use photo-imageable solder masks that provide superior resolution and edge definition compared to screen-printed alternatives. The curing process should achieve complete polymerization, resulting in optimal chemical resistance and mechanical properties that withstand harsh operating environments.

Electrical Performance Characteristics

Impedance Control and Signal Integrity

Controlled impedance requirements have become standard for most modern PCB Circuit Board applications, particularly in high-speed digital and RF designs. Quality manufacturers maintain impedance tolerances within ±10% through careful stackup design, consistent dielectric thickness control, and precise trace geometry. Impedance test coupons integrated into production panels provide verification that electrical specifications meet design requirements.

Signal integrity considerations extend beyond basic impedance control to include crosstalk mitigation, return path continuity, and via optimization. High-quality boards incorporate proper ground plane design, strategic layer stackup arrangements, and optimized via structures to minimize signal degradation. Time domain reflectometry (TDR) testing can verify impedance uniformity along critical signal paths, ensuring consistent performance across the entire PCB Circuit Board.

Thermal Management Properties

Effective thermal management becomes increasingly critical as electronic devices achieve higher power densities and miniaturization. Quality PCB Circuit Board designs incorporate thermal vias, copper pours, and strategic component placement to facilitate heat dissipation. Thermal conductivity of substrate materials and copper layer distribution directly impact thermal performance, with specialized materials like metal-core PCBs offering superior heat transfer capabilities for power electronics.

Thermal cycling testing validates board reliability under temperature extremes, with quality boards withstanding hundreds of cycles between -40°C and +125°C without delamination or electrical failures. Coefficient of thermal expansion (CTE) matching between different board layers prevents stress-induced cracking and maintains long-term reliability in demanding applications.

Quality Assurance and Testing Protocols

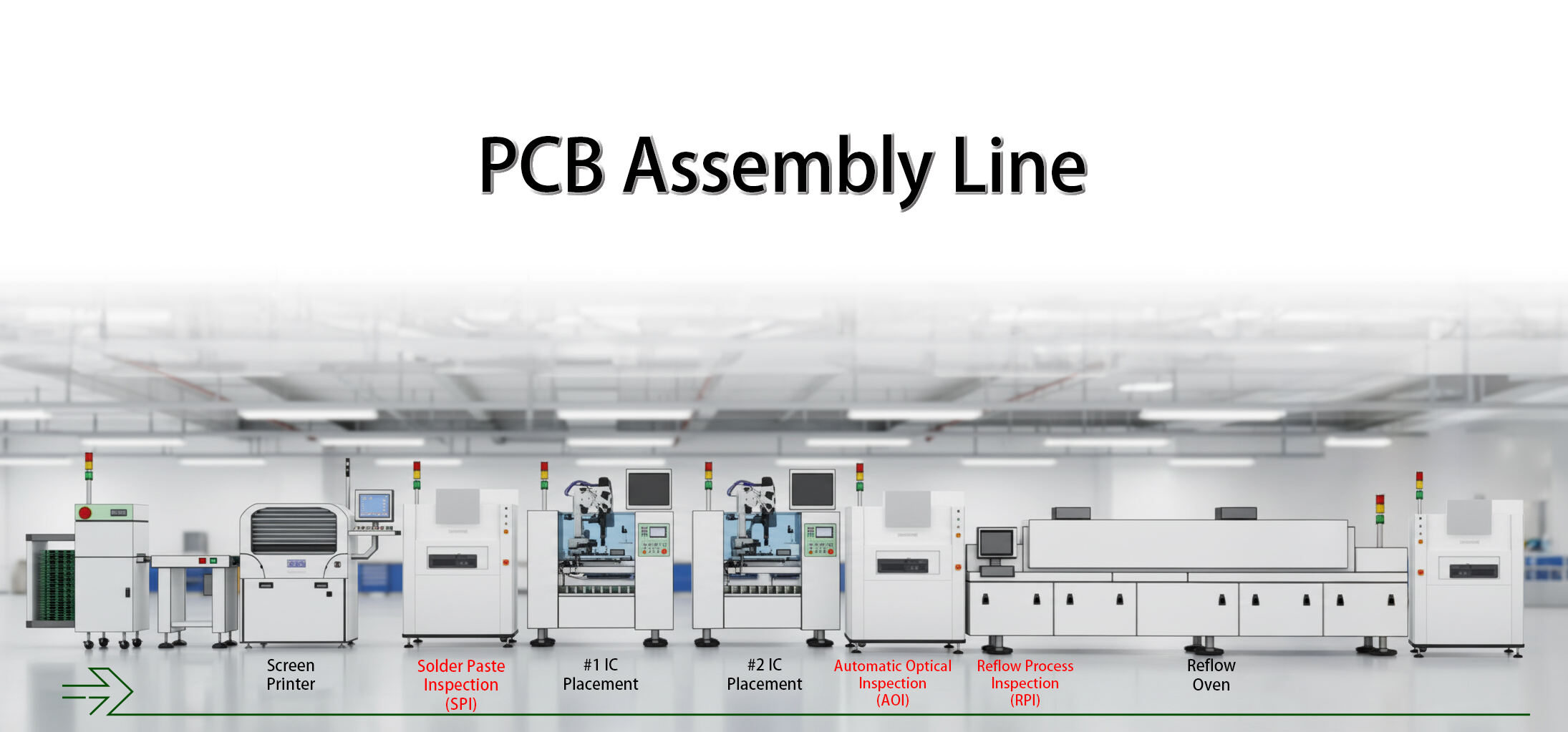

Automated Optical Inspection

Advanced manufacturing facilities employ automated optical inspection (AOI) systems to detect defects that manual inspection might miss. These systems capture high-resolution images of PCB Circuit Board surfaces, comparing them against reference standards to identify issues such as copper shorts, opens, incorrect pad sizes, or solder mask defects. AOI technology provides consistent, repeatable inspection results while maintaining high throughput rates essential for volume production.

Modern AOI systems incorporate artificial intelligence algorithms that learn from inspection results, continuously improving defect detection accuracy while reducing false positives. This technology ensures that only boards meeting strict quality standards proceed to subsequent manufacturing steps, preventing defective PCB Circuit Board units from reaching customers and potentially causing field failures.

Electrical Testing and Verification

Comprehensive electrical testing validates PCB Circuit Board functionality before shipment, including continuity checks, insulation resistance measurements, and high-voltage testing. Flying probe testers provide flexible, programmable testing capabilities suitable for prototype and low-volume production, while dedicated test fixtures offer higher throughput for volume applications. Test coverage should approach 100% for critical nets, ensuring all electrical connections function as intended.

In-circuit testing (ICT) can detect manufacturing defects such as solder bridges, open circuits, incorrect component values, and missing components in assembled boards. Quality manufacturers maintain detailed test records and implement statistical process control to identify trends and prevent systematic quality issues from affecting PCB Circuit Board production.

Supplier Evaluation and Certification Standards

Industry Certifications and Standards Compliance

Reputable PCB Circuit Board manufacturers maintain certifications demonstrating compliance with international quality and environmental standards. ISO 9001 certification indicates implementation of comprehensive quality management systems, while ISO 14001 addresses environmental management practices. IPC standards, particularly IPC-6012 for rigid PCBs and IPC-A-610 for acceptability criteria, provide specific requirements for manufacturing quality and inspection criteria.

Additional certifications such as UL recognition, RoHS compliance, and REACH regulation adherence ensure boards meet safety and environmental requirements for global markets. Military and aerospace applications may require additional certifications like AS9100 or IPC-6018 for high-reliability applications where PCB Circuit Board failures could have severe consequences.

Manufacturing Capability Assessment

Evaluating supplier manufacturing capabilities involves examining equipment sophistication, process controls, and quality systems. Advanced facilities feature modern equipment such as laser drilling systems, direct imaging exposure units, and automated plating lines that enable consistent, high-quality production. Process documentation should demonstrate statistical process control implementation, with regular monitoring of key parameters affecting PCB Circuit Board quality.

Supplier audits provide insights into manufacturing practices, quality systems, and continuous improvement initiatives. Look for evidence of investment in equipment upgrades, employee training programs, and process optimization efforts that indicate commitment to maintaining competitive manufacturing capabilities and consistent PCB Circuit Board quality.

Cost Considerations and Value Analysis

Total Cost of Ownership Perspective

While initial PCB Circuit Board costs represent an obvious consideration, total cost of ownership encompasses additional factors such as reliability, yield rates, and potential field failure costs. Higher-quality boards may command premium pricing but often deliver superior reliability that reduces warranty costs, customer support expenses, and potential brand reputation damage from product failures.

Quality boards typically achieve higher assembly yields due to consistent manufacturing tolerances and superior surface finishes that facilitate reliable solder joint formation. Reduced rework costs and faster assembly throughput can offset initial price premiums, particularly in volume production scenarios where small improvements in yield translate to significant cost savings.

Design for Manufacturing Optimization

Collaborating with experienced PCB Circuit Board manufacturers during design phases can identify optimization opportunities that reduce costs while maintaining quality standards. Design rule checks (DRC) ensure layouts comply with manufacturer capabilities, preventing costly design revisions or yield issues during production. Standardizing on common materials, layer counts, and via sizes can leverage manufacturer purchasing power and established processes to achieve better pricing.

Early supplier engagement enables design modifications that improve manufacturability without compromising functionality. Simple changes such as adjusting trace widths, via sizes, or component spacing can significantly impact manufacturing costs while maintaining electrical performance requirements for the PCB Circuit Board application.

FAQ

What minimum specifications should I require for high-quality PCB Circuit Board manufacturing

High-quality PCB Circuit Board manufacturing should meet IPC-6012 Class 2 or Class 3 standards depending on application criticality. Minimum requirements include ±0.05mm drilling tolerance, ±10% impedance control, 0.1mm minimum trace width capability, and comprehensive electrical testing with 100% continuity verification. Substrate materials should comply with IPC-4101 specifications with appropriate Tg ratings for operating temperature ranges.

How can I verify PCB Circuit Board quality before accepting delivery

Implement incoming inspection procedures including visual examination for surface defects, dimensional verification using calibrated measuring equipment, and electrical testing of sample boards. Request manufacturer test reports, material certifications, and process control charts that demonstrate consistent quality during production. Consider third-party testing for critical applications or when establishing relationships with new PCB Circuit Board suppliers.

What are the most common quality issues that affect PCB Circuit Board reliability

Common quality issues include poor copper adhesion leading to delamination, inadequate via filling causing reliability failures, solder mask misregistration affecting assembly yields, and contamination from improper cleaning processes. Dimensional variations outside specification tolerances can cause component placement issues, while insufficient electrical testing may allow defective PCB Circuit Board units to reach assembly operations.

How do material choices impact long-term PCB Circuit Board performance

Material selection directly affects thermal performance, electrical characteristics, and mechanical reliability of PCB Circuit Board assemblies. Higher Tg substrates provide better thermal stability, while low-loss materials improve high-frequency performance. Copper thickness selection influences current-carrying capacity and thermal dissipation, while surface finish choices affect solderability and long-term reliability in various operating environments.

Table of Contents

- Understanding PCB Circuit Board Materials and Construction

- Manufacturing Process Quality Indicators

- Electrical Performance Characteristics

- Quality Assurance and Testing Protocols

- Supplier Evaluation and Certification Standards

- Cost Considerations and Value Analysis

-

FAQ

- What minimum specifications should I require for high-quality PCB Circuit Board manufacturing

- How can I verify PCB Circuit Board quality before accepting delivery

- What are the most common quality issues that affect PCB Circuit Board reliability

- How do material choices impact long-term PCB Circuit Board performance