Modern electronics manufacturing demands precision, reliability, and innovation at every stage of development. Professional circuit board design services have become indispensable for companies seeking to create cutting-edge electronic products that meet stringent performance standards and regulatory requirements. These specialized services bridge the gap between conceptual ideas and manufacturable electronic systems, ensuring that complex designs translate seamlessly from theory to production-ready hardware.

The complexity of contemporary electronic devices requires sophisticated design methodologies that account for signal integrity, electromagnetic interference, thermal management, and manufacturing constraints. Professional designers possess the expertise to navigate these challenges while optimizing performance characteristics and minimizing production costs. Their comprehensive understanding of industry standards and manufacturing processes ensures that designs not only function correctly but also meet quality benchmarks expected in competitive markets.

Technical Expertise and Industry Knowledge

Advanced Design Capabilities

Professional circuit board designers bring years of specialized training and hands-on experience to every project. They understand the intricate relationships between component placement, trace routing, and electrical performance that directly impact product functionality. Their expertise encompasses high-speed digital design, analog circuit optimization, mixed-signal integration, and power management systems that require precise engineering approaches.

These professionals stay current with emerging technologies and design methodologies, incorporating the latest advances in materials science, manufacturing techniques, and testing protocols into their work. They understand how different substrate materials affect signal propagation, how via placement influences electromagnetic compatibility, and how thermal considerations impact long-term reliability. This knowledge enables them to make informed decisions that optimize both performance and manufacturability.

Regulatory Compliance and Standards

Navigating the complex landscape of industry standards and regulatory requirements demands specialized knowledge that professional designers possess. They understand IPC standards for design and manufacturing, electromagnetic compatibility requirements, safety certifications, and environmental regulations that apply to electronic products. This expertise ensures that designs comply with relevant standards from the initial concept phase through final production.

Professional designers also understand regional variations in regulatory requirements, enabling companies to develop products that can be marketed globally without extensive redesign efforts. They incorporate design features that facilitate compliance testing and certification processes, reducing time-to-market and avoiding costly design revisions during later development stages.

Cost Optimization and Manufacturing Efficiency

Design for Manufacturing Principles

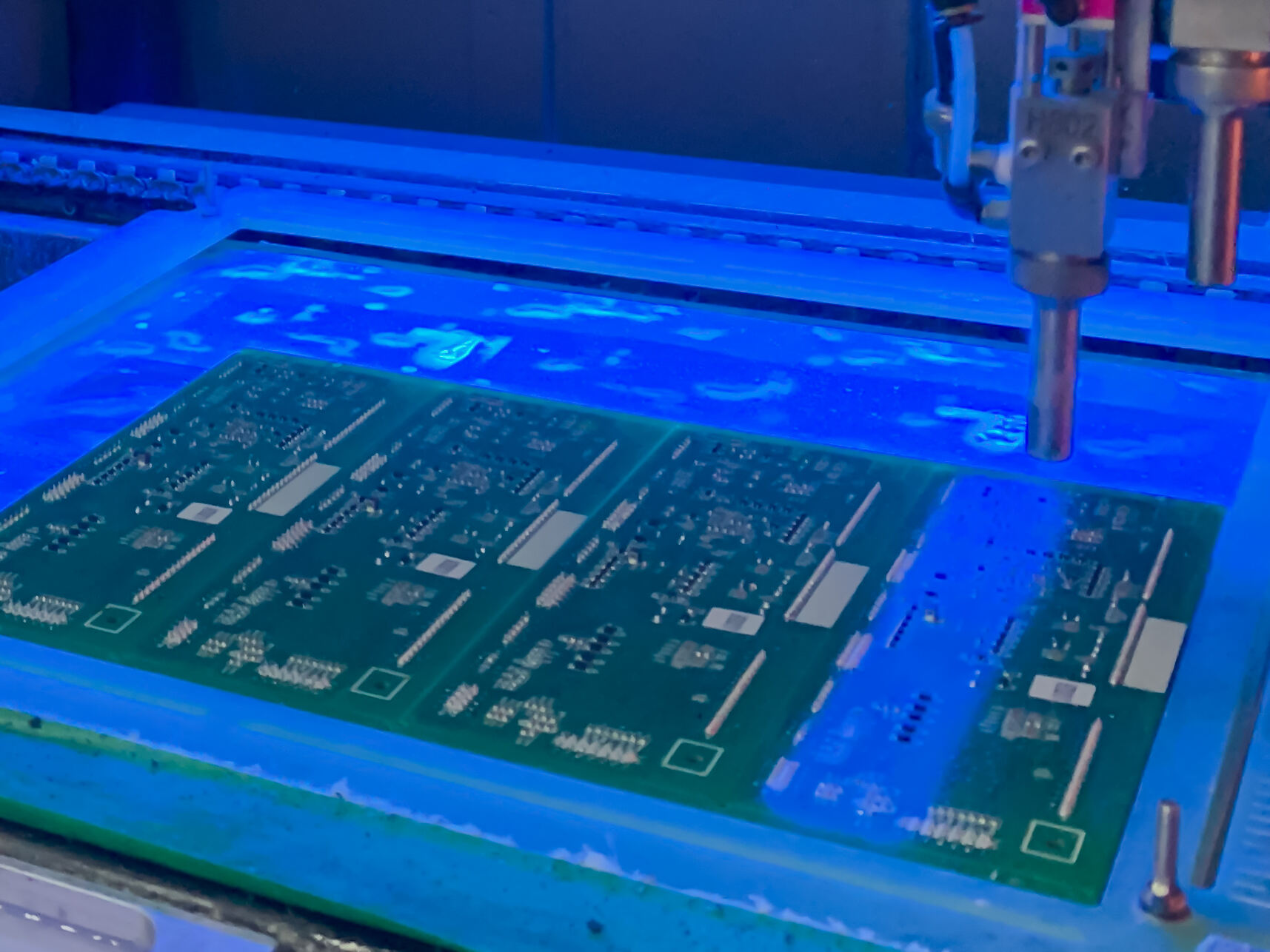

Experienced designers apply design for manufacturing principles that significantly impact production costs and yield rates. They understand how component selection, board layout, and assembly requirements affect manufacturing complexity and associated costs. Professional circuit board design services optimize designs for automated assembly processes, reducing labor costs and improving consistency across production runs.

These professionals also consider supply chain factors when making design decisions, selecting components that are readily available and cost-effective while meeting performance requirements. They understand how design choices affect fabrication processes, assembly complexity, and testing requirements, enabling them to balance performance objectives with manufacturing constraints effectively.

Risk Mitigation and Quality Assurance

Professional designers implement comprehensive design review processes that identify potential issues before they become costly problems during manufacturing or field deployment. They conduct thorough design rule checks, signal integrity analysis, and electromagnetic compatibility assessments that prevent common failure modes and ensure robust performance under various operating conditions.

Their systematic approach to quality assurance includes detailed documentation, revision control, and testing protocols that support reliable manufacturing processes. They establish clear specifications for materials, processes, and acceptance criteria that enable consistent production results and facilitate troubleshooting when issues arise.

Advanced Technology Integration

High-Speed Digital Design

Modern electronic systems increasingly require high-speed digital interfaces that demand specialized design expertise. Professional designers understand transmission line theory, impedance control, crosstalk mitigation, and timing analysis techniques necessary for reliable high-speed signal transmission. They apply advanced simulation tools to optimize trace geometries, via structures, and termination strategies that ensure signal integrity across the entire frequency spectrum.

These specialists also understand the implications of power delivery network design on high-speed digital performance. They implement sophisticated power distribution strategies that minimize noise coupling between digital and analog circuits while maintaining stable operating voltages under dynamic load conditions. Their expertise ensures that complex digital systems operate reliably without compromising analog circuit performance.

Multi-Layer Board Architecture

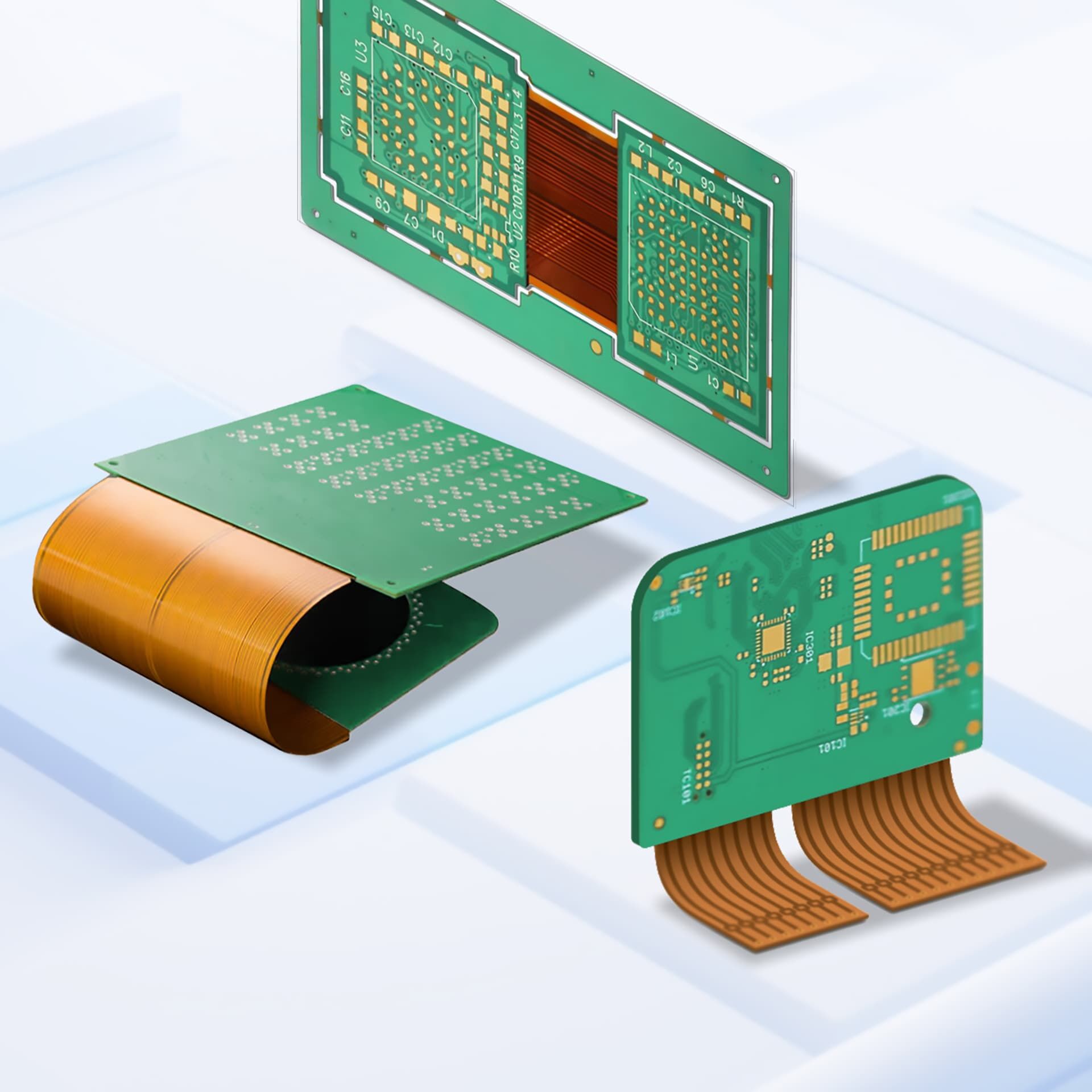

Complex electronic systems often require multi-layer board architectures that optimize space utilization while maintaining electrical performance. Professional designers understand layer stack-up design principles that balance electrical requirements with mechanical constraints and manufacturing capabilities. They optimize via placement and routing strategies that minimize electromagnetic interference while providing reliable interconnections between layers.

Their expertise extends to advanced packaging technologies including embedded components, blind and buried vias, and high-density interconnect structures. They understand how these technologies affect manufacturing processes, reliability characteristics, and cost considerations, enabling them to make informed decisions about appropriate technology applications for specific project requirements.

Project Management and Communication

Collaborative Development Process

Professional circuit board design services establish clear communication channels and project management protocols that ensure successful collaboration with client engineering teams. They understand the importance of regular design reviews, milestone tracking, and documentation standards that facilitate effective project coordination. Their systematic approach to project management minimizes delays and ensures that deliverables meet established specifications and schedules.

These professionals also provide valuable consultation during the conceptual design phase, offering insights that can significantly impact product architecture decisions. They collaborate effectively with mechanical engineers, software developers, and system architects to ensure that circuit board designs integrate seamlessly with other product subsystems and meet overall performance objectives.

Documentation and Support

Comprehensive documentation is essential for successful product development and manufacturing processes. Professional designers provide detailed fabrication drawings, assembly instructions, bill of materials, and testing specifications that support reliable manufacturing operations. Their documentation standards facilitate design reviews, enable effective communication with manufacturing partners, and provide essential information for future product updates or modifications.

Professional services also include ongoing support during manufacturing ramp-up and production phases. They provide technical assistance for resolving manufacturing issues, optimizing assembly processes, and implementing design changes that improve yield rates or reduce costs. This continued support ensures that designs perform as intended throughout the product lifecycle.

FAQ

What factors should companies consider when selecting professional circuit board design services

Companies should evaluate design experience in relevant technology areas, understanding of applicable industry standards, project management capabilities, and communication protocols. Important considerations include the service provider's track record with similar projects, their access to advanced design tools and simulation capabilities, and their ability to support manufacturing and testing requirements. Additionally, companies should assess the provider's quality assurance processes, documentation standards, and ongoing support capabilities.

How do professional design services impact product development timelines

Professional design services typically accelerate product development by applying proven design methodologies and avoiding common pitfalls that can cause delays. Their expertise in design for manufacturing principles reduces the likelihood of design revisions during manufacturing phases, while their understanding of regulatory requirements helps ensure successful certification processes. However, the initial design phase may require additional time for thorough analysis and optimization compared to less rigorous approaches.

What cost benefits do professional circuit board design services provide

Professional services often reduce overall project costs through optimized component selection, improved manufacturing yields, and reduced design revision cycles. Their expertise in design for manufacturing principles minimizes assembly complexity and associated labor costs, while their understanding of supply chain factors helps control component costs. Additionally, their quality assurance processes reduce the risk of field failures and associated warranty costs.

How do professional designers ensure electromagnetic compatibility in complex systems

Professional designers apply systematic electromagnetic compatibility design principles including proper grounding strategies, shielding techniques, and signal routing optimization. They use advanced simulation tools to analyze electromagnetic field distributions and identify potential interference sources before manufacturing. Their expertise includes understanding of regulatory EMC requirements and testing protocols, enabling them to design products that pass certification testing without extensive modifications.

Table of Contents

- Technical Expertise and Industry Knowledge

- Cost Optimization and Manufacturing Efficiency

- Advanced Technology Integration

- Project Management and Communication

-

FAQ

- What factors should companies consider when selecting professional circuit board design services

- How do professional design services impact product development timelines

- What cost benefits do professional circuit board design services provide

- How do professional designers ensure electromagnetic compatibility in complex systems