The rapid evolution of 5G technology has fundamentally transformed the telecommunications landscape, demanding unprecedented performance standards from electronic components. At the heart of this technological revolution lies the critical role of printed circuit boards, where material selection and design optimization directly impact signal integrity and overall device performance. Rogers PCB technology has emerged as a leading solution for addressing the stringent requirements of 5G applications, offering superior electrical properties that enable reliable high-frequency operations.

Modern 5G infrastructure operates across multiple frequency bands, including sub-6 GHz and millimeter wave frequencies extending up to 28 GHz and beyond. These elevated operating frequencies present unique challenges for traditional PCB materials, which often exhibit excessive dielectric losses and inconsistent performance characteristics. The demanding nature of 5G applications requires PCB substrates that maintain stable electrical properties across wide temperature ranges while minimizing signal degradation through superior material engineering.

Understanding High-Frequency PCB Requirements in 5G Systems

Dielectric Properties and Signal Integrity

The foundation of effective 5G PCB design rests upon carefully selected dielectric materials that exhibit low loss tangent values and consistent dielectric constants across operational frequency ranges. Rogers materials demonstrate exceptional stability in these critical parameters, maintaining predictable electrical behavior even under varying environmental conditions. This consistency proves essential for maintaining signal integrity in complex 5G transceiver circuits where even minor variations can significantly impact performance.

Signal integrity becomes increasingly challenging as frequencies approach millimeter wave ranges, where traditional FR-4 PCB materials begin to exhibit prohibitive losses. The molecular structure of advanced Rogers substrates minimizes dielectric absorption and provides enhanced dimensional stability, reducing the likelihood of impedance variations that could compromise signal quality. These material advantages translate directly into improved system performance and reduced error rates in high-speed data transmission applications.

Thermal Management Considerations

Effective thermal management represents another critical aspect of 5G PCB design, as high-frequency components generate substantial heat that must be efficiently dissipated to maintain optimal performance. Rogers PCB materials incorporate specialized thermal interface properties that facilitate heat transfer while maintaining electrical isolation between circuit elements. This dual functionality proves particularly valuable in dense 5G antenna arrays where multiple high-power amplifiers operate in close proximity.

The coefficient of thermal expansion in Rogers materials closely matches that of copper conductors, minimizing mechanical stress during temperature cycling and enhancing long-term reliability. This thermal compatibility reduces the risk of delamination and conductor fractures that can occur in conventional PCB designs subjected to the demanding thermal environments typical of 5G base station equipment.

Rogers Material Technologies for 5G Applications

RO4000 Series Performance Characteristics

The RO4000 series represents a breakthrough in PCB substrate technology, offering exceptional electrical performance combined with processing compatibility similar to traditional epoxy-glass materials. These hydrocarbon-ceramic laminates provide stable dielectric constants and low loss tangent values that remain consistent across the frequency spectrum utilized by 5G systems. The woven glass reinforcement structure ensures mechanical stability while maintaining the electrical uniformity required for precision high-frequency circuits.

Manufacturing processes for RO4000 series materials align closely with standard PCB fabrication techniques, enabling cost-effective production without requiring specialized equipment or extensive process modifications. This compatibility advantage allows manufacturers to leverage existing production capabilities while achieving the enhanced performance characteristics essential for 5G applications. The material's excellent dimensional stability throughout the fabrication process ensures precise impedance control and consistent electrical performance across production batches.

Advanced Rogers Substrate Options

Beyond the RO4000 series, Rogers Corporation offers specialized materials designed for specific 5G application requirements, including ultra-low-loss substrates for millimeter wave applications and high-thermal-conductivity options for power amplifier circuits. These advanced materials incorporate proprietary filler technologies and resin systems optimized for specific performance parameters, enabling designers to select the most appropriate substrate for their particular application requirements.

The RT/duroid series provides exceptional performance for the most demanding millimeter wave applications, featuring extremely low dielectric loss and minimal dispersion characteristics that preserve signal fidelity across wide bandwidths. These materials enable the development of high-gain antenna arrays and low-noise amplifier circuits that form the foundation of advanced 5G infrastructure systems.

Design Optimization Strategies for 5G PCB Implementation

Stack-up Configuration and Layer Management

Optimal PCB stack-up design for 5G applications requires careful consideration of signal routing, power distribution, and electromagnetic compatibility requirements. Rogers materials enable the implementation of controlled impedance structures that maintain consistent electrical characteristics throughout complex multilayer configurations. The selection of appropriate core and prepreg thicknesses directly impacts the achievable impedance values and coupling characteristics between adjacent circuit elements.

Layer sequencing in mixed-signal 5G PCB designs must account for the varying performance requirements of different circuit blocks, with critical RF sections utilizing premium Rogers materials while digital control circuits may employ more cost-effective substrates. This hybrid approach optimizes both performance and manufacturing costs while maintaining the electrical integrity required for reliable 5G operation.

Via Technology and Interconnect Design

High-frequency PCB design demands careful attention to via structures and interconnect methodologies, as these elements can introduce significant parasitic effects that degrade signal quality. Rogers materials support advanced via technologies including microvias and controlled-depth drilling that minimize discontinuities in high-frequency signal paths. The low dielectric loss characteristics of Rogers substrates help maintain signal integrity even through complex via transitions between PCB layers.

Blind and buried via technologies become increasingly important in dense 5G PCB layouts where space constraints require efficient utilization of available routing layers. The excellent dimensional stability of Rogers materials ensures precise via registration and consistent electrical performance throughout the interconnect structure, enabling reliable operation across the demanding frequency ranges utilized by 5G systems.

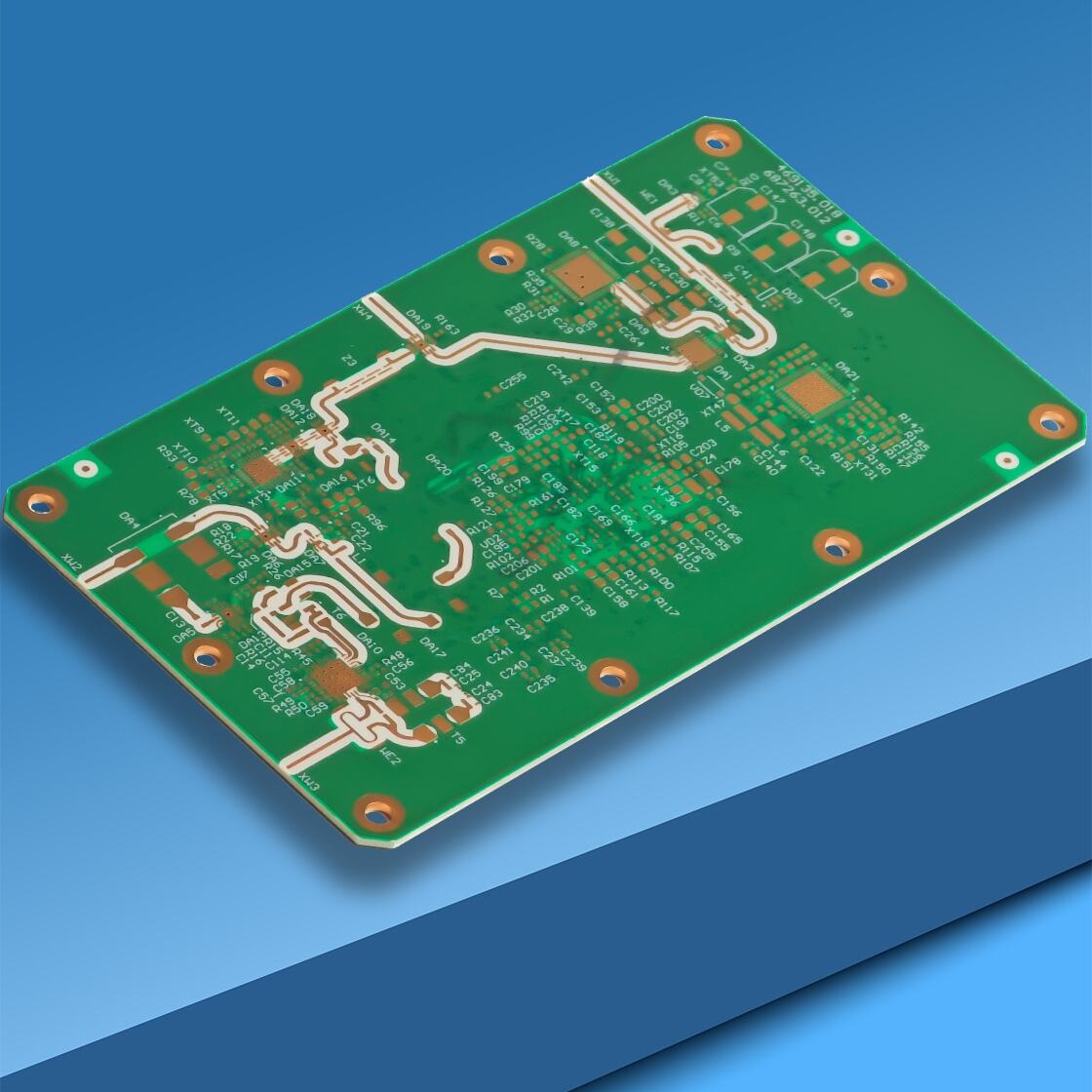

Manufacturing Excellence in Rogers PCB Production

Process Control and Quality Assurance

The manufacturing of high-performance Rogers PCB assemblies requires stringent process control measures to ensure consistent electrical and mechanical properties throughout production. Specialized handling procedures protect the sensitive dielectric materials from contamination and moisture absorption that could compromise performance characteristics. Temperature and humidity control during fabrication processes proves critical for maintaining the dimensional stability and electrical properties that define Rogers material advantages.

Quality assurance protocols for Rogers PCB manufacturing include comprehensive electrical testing at multiple frequency points to verify performance compliance with design specifications. Advanced measurement techniques such as time-domain reflectometry and vector network analysis provide detailed characterization of electrical parameters across the operational frequency spectrum, ensuring that finished PCB assemblies meet the stringent requirements of 5G applications.

Advanced Fabrication Techniques

State-of-the-art Rogers PCB fabrication incorporates precision drilling technologies that minimize via stub lengths and maintain controlled impedance characteristics throughout complex multilayer structures. Laser drilling capabilities enable the creation of microvias with aspect ratios optimized for high-frequency performance while maintaining mechanical reliability under thermal cycling conditions typical of 5G operating environments.

Surface finishing options for Rogers PCB assemblies include specialized plating processes that enhance solderability while minimizing surface roughness effects that can impact high-frequency signal propagation. Advanced surface treatments such as immersion silver and ENIG (Electroless Nickel Immersion Gold) provide excellent electrical performance while ensuring long-term reliability in demanding 5G deployment scenarios.

Performance Validation and Testing Methodologies

High-Frequency Characterization Techniques

Comprehensive validation of Rogers PCB performance in 5G applications requires sophisticated measurement techniques capable of accurately characterizing electrical behavior across millimeter wave frequency ranges. Vector network analyzer measurements provide detailed insertion loss and return loss data that quantify signal integrity performance under actual operating conditions. These measurements validate design predictions and ensure compliance with stringent 5G performance specifications.

Time-domain analysis techniques offer complementary insights into PCB performance characteristics, revealing impedance discontinuities and reflection phenomena that could impact signal quality. The combination of frequency-domain and time-domain measurements provides comprehensive validation of Rogers PCB electrical performance, ensuring reliable operation across the diverse frequency bands utilized by 5G systems.

Environmental Stress Testing

Long-term reliability validation requires extensive environmental stress testing that subjects Rogers PCB assemblies to temperature cycling, humidity exposure, and mechanical vibration conditions representative of actual 5G deployment scenarios. These accelerated aging tests verify the dimensional stability and electrical consistency of Rogers materials under adverse environmental conditions, ensuring reliable performance throughout the intended service life.

Thermal cycling protocols specifically designed for 5G PCB validation incorporate temperature ranges and cycling rates that simulate the thermal stress experienced by base station equipment during normal operation. The superior thermal expansion characteristics of Rogers materials demonstrate exceptional resistance to delamination and conductor cracking under these demanding test conditions.

Cost-Effectiveness and Economic Considerations

Total Cost of Ownership Analysis

While Rogers PCB materials command premium pricing compared to standard FR-4 substrates, comprehensive cost analysis must consider the total cost of ownership throughout the product lifecycle. The enhanced electrical performance and reliability of Rogers materials often justify the initial investment through reduced field failures, lower maintenance requirements, and extended service life in 5G applications. These factors contribute to improved return on investment for 5G infrastructure deployments.

Manufacturing efficiency gains realized through Rogers material compatibility with standard PCB fabrication processes help offset material cost premiums by minimizing production complexity and reducing yield losses. The predictable electrical characteristics and dimensional stability of Rogers substrates contribute to higher first-pass yield rates and reduced rework requirements during PCB assembly operations.

Market Positioning and Competitive Advantages

The adoption of Rogers PCB technology provides significant competitive advantages in the rapidly evolving 5G marketplace, enabling the development of higher-performance products with enhanced reliability characteristics. Early adoption of advanced PCB materials positions manufacturers to capitalize on emerging 5G opportunities while establishing technical leadership in high-frequency applications. These advantages translate into improved market positioning and increased customer confidence in product reliability.

Supply chain considerations for Rogers PCB materials include establishing strategic partnerships with qualified manufacturers capable of handling advanced substrate technologies. The specialized nature of Rogers materials requires careful supplier qualification and ongoing quality monitoring to ensure consistent performance across production volumes, particularly as 5G deployment scales accelerate globally.

FAQ

What makes Rogers PCB materials superior for 5G applications compared to standard FR-4

Rogers PCB materials offer significantly lower dielectric losses and more stable electrical properties across the high frequencies used in 5G systems. Unlike FR-4, which exhibits increasing losses at frequencies above 1 GHz, Rogers materials maintain consistent performance characteristics well into millimeter wave frequency ranges. The controlled dielectric constant and low loss tangent of Rogers substrates ensure signal integrity preservation that is essential for reliable 5G communications.

How do Rogers PCB materials handle thermal management in 5G base stations

Rogers PCB substrates incorporate enhanced thermal conductivity properties and coefficient of thermal expansion matching that closely aligns with copper conductors. This thermal compatibility minimizes mechanical stress during temperature cycling and provides efficient heat dissipation pathways for high-power 5G components. The superior thermal management capabilities help maintain consistent electrical performance while extending component lifespan in demanding base station environments.

Are Rogers PCB materials compatible with standard manufacturing processes

Many Rogers PCB materials, particularly the RO4000 series, are designed for compatibility with conventional PCB fabrication processes, requiring minimal modifications to existing manufacturing equipment. This compatibility enables cost-effective production while achieving enhanced electrical performance characteristics. However, specialized handling procedures and environmental controls are recommended to optimize material properties and ensure consistent manufacturing results.

What frequency ranges can Rogers PCB materials effectively support in 5G systems

Rogers PCB materials support the complete frequency spectrum utilized by 5G systems, from sub-6 GHz bands up to millimeter wave frequencies exceeding 28 GHz. Different Rogers material grades are optimized for specific frequency ranges, with ultra-low-loss options available for the most demanding millimeter wave applications. The consistent electrical properties across these frequency ranges enable reliable signal transmission and reception in diverse 5G deployment scenarios.

Table of Contents

- Understanding High-Frequency PCB Requirements in 5G Systems

- Rogers Material Technologies for 5G Applications

- Design Optimization Strategies for 5G PCB Implementation

- Manufacturing Excellence in Rogers PCB Production

- Performance Validation and Testing Methodologies

- Cost-Effectiveness and Economic Considerations

-

FAQ

- What makes Rogers PCB materials superior for 5G applications compared to standard FR-4

- How do Rogers PCB materials handle thermal management in 5G base stations

- Are Rogers PCB materials compatible with standard manufacturing processes

- What frequency ranges can Rogers PCB materials effectively support in 5G systems