pCB בתדר גבוה

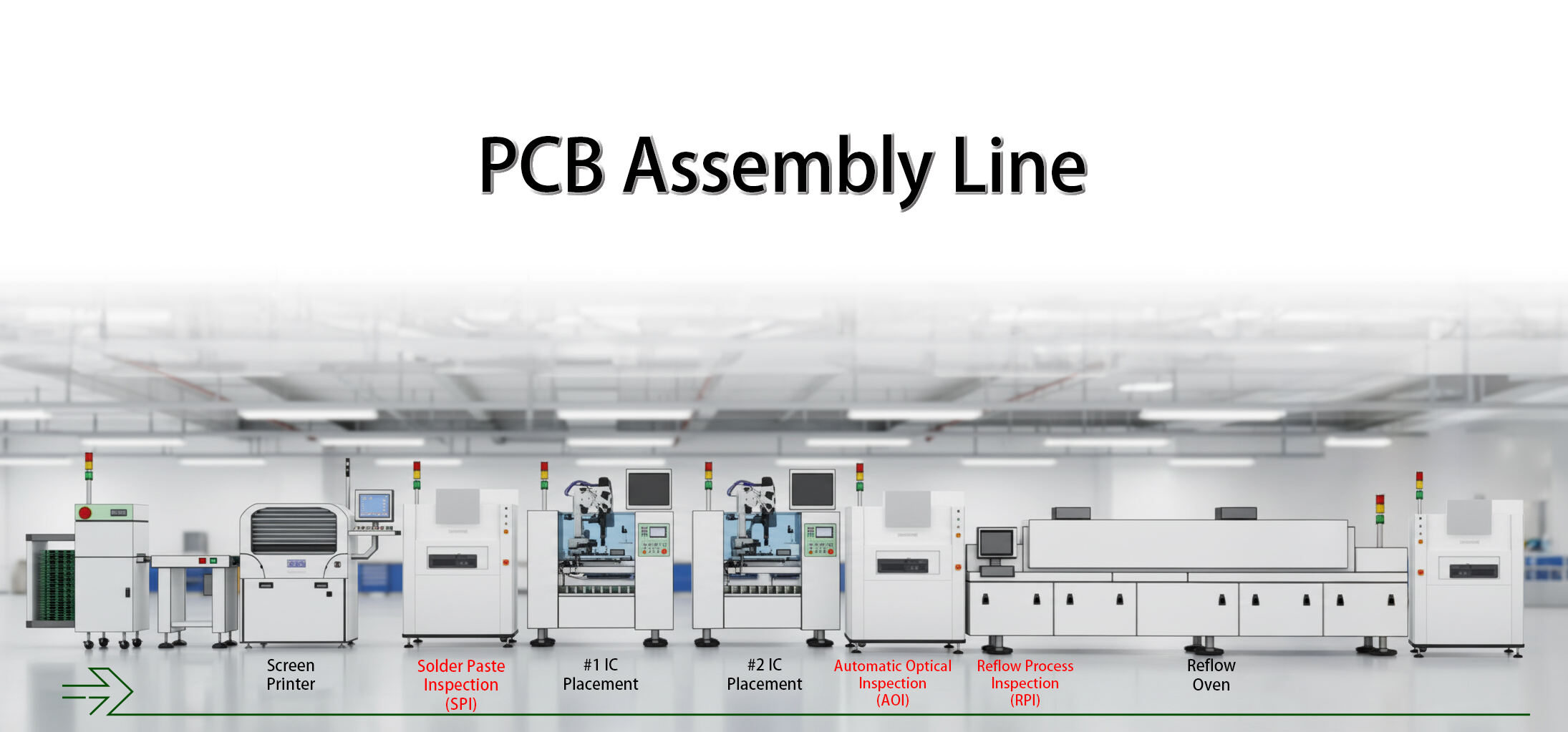

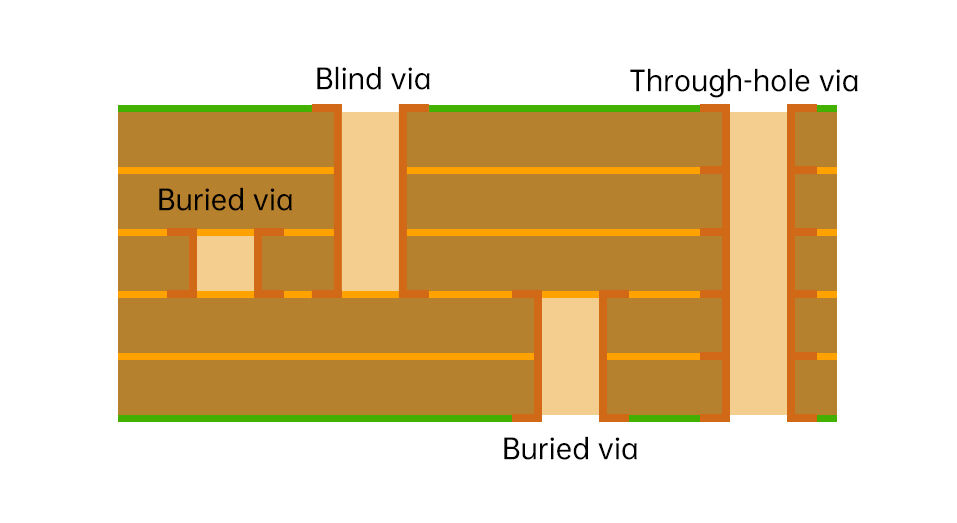

פלטות PCB בתדר גבוה (Printed Circuit Boards) מייצגות קטגוריה מיוחדת של פלטות מעגלים שתוכננו כדי להתמודד עם אותות בתדרים הנעים מעל 500 מגה-הרץ. רכיבים מתוחכמים אלו מעוצבים על מנת לשמור על שלמות האות, תוך מינימום של אובדן ועיכובים אלקטרו-מגנטיים בתדרים מוגבשים. בניית פלטות PCB בתדר גבוה כוללת בחירה זהירה בחומרים, ובדרך כלל נעשה שימוש בחומרי בסיס עם אובדן נמוך כמו Rogers, Taconic או חומרים מבוססי PTFE, אשר מציעים תכונות חשמליות טובות בהשוואה לחומרי FR4 סטנדרטיים. ללוחות אלו יש עקומות התנגדות מבוקרות, טכניקות יישור מיוחדות, ובעתים קרובות משולבות בהם אלמנטים מתקדמים של עיצוב כגון תצורות microstrip ו-stripline. פלטות PCB בתדר גבוה מהוות בסיס לציוד תקשורת מודרני, מערכות מכ”ם, תקשורת לוויינית ויישומים דיגיטליים במהירות גבוהה. הבנייה הייחודית שלהן מאפשרת העברה יעילה של אותות, תוך מינימום של דעיכה, מה שהופך אותן לאispensABLE ביישומים שבהם שלמות הנתונים בתדרים גבוהים היא קריטית. תהליך הייצור מחייב דיוק מרבי בטיפול בחומרים ובשיטות הייצור, כדי להבטיח ביצועים חשמליים עקביים בכל הלוח. לפלטות אלו לעתים קרובות משולבים שיקולים נוספים בעיצוב, כגון עובי דיאלקטרי מבוקר, משקל נחושת ספציפי וסידורי פני שטח מיוחדים, על מנת לשמור על ביצועים אופטימליים בתדרים גבוהים.