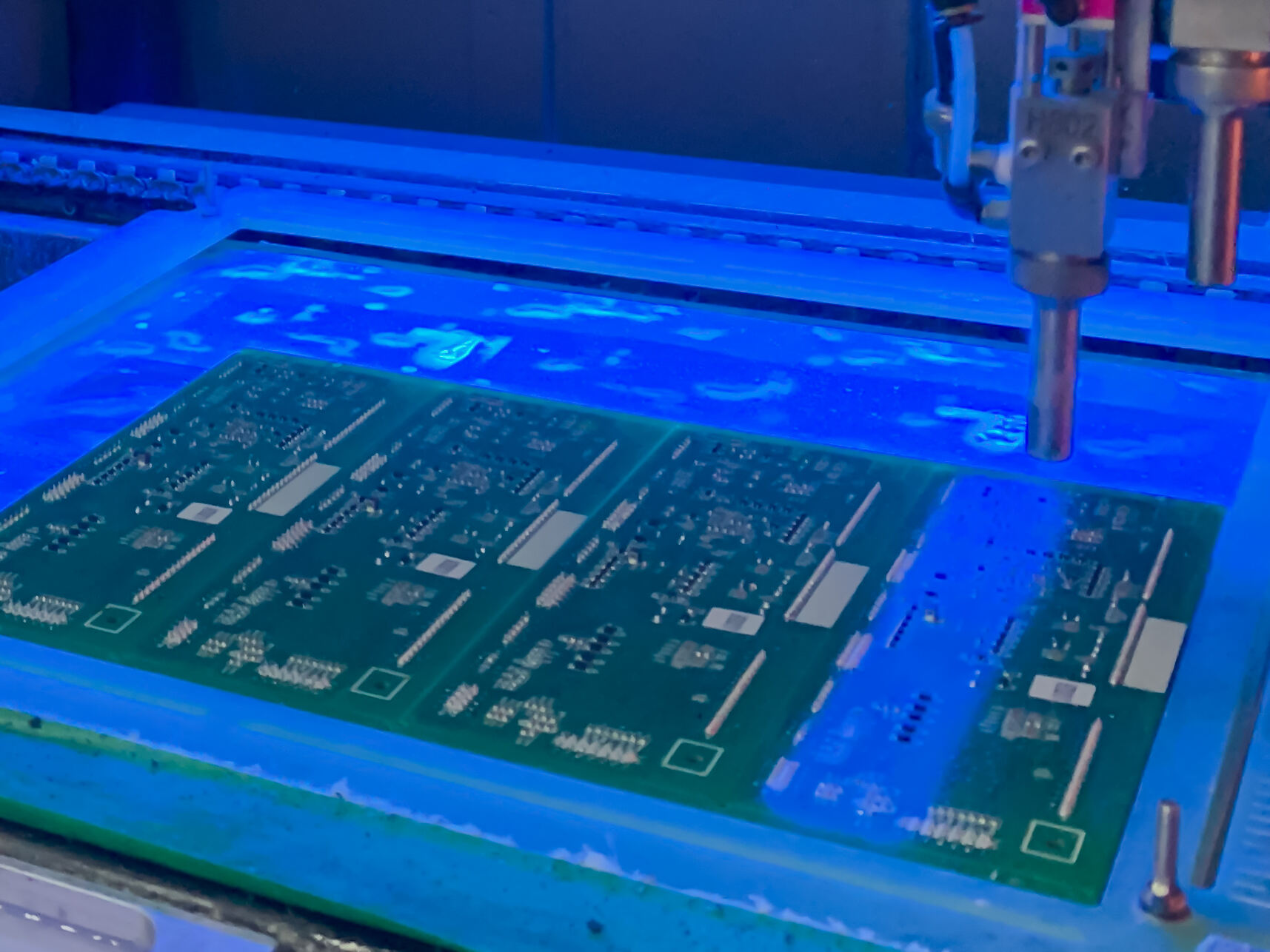

nima pcb taxta

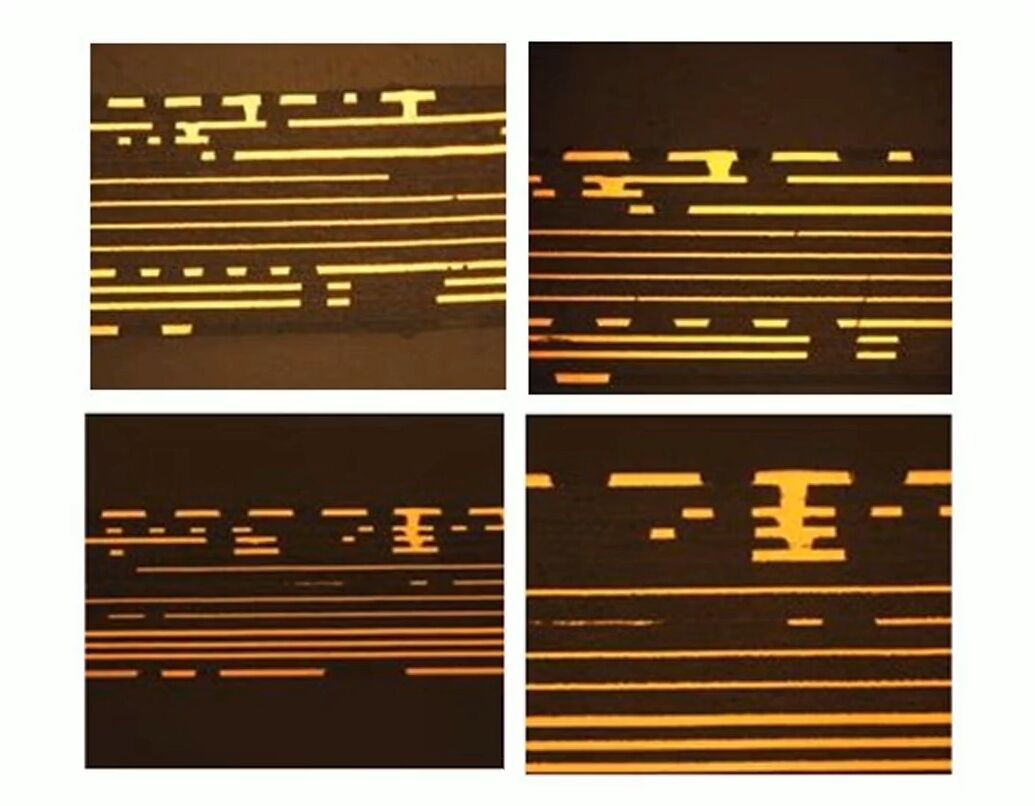

Printsiallangan platadagi (PCB) elektron sxema zamonaviy elektronikaning asosiy qismi bo'lib, uning mexanik tayanchi va elektr uloqtiruvchi sifatida ishlaydi. Ushbu platlar odatda shishali to'q simobli materialdan tashkil topgan bo'lib, ularga mis yo'llari etch qilinadi va elektr aloqasi yaratiladi. PCB lar nuqta- nuqtaga sim o'rash zarurini bekor qilish orqali elektronika sanoatini inqilob qildi va elektron qurilmalarni ishonchliroq, ixchamroq va arzonroq qilib ishlab chiqarish imkonini berdi. Platalar sxema loyihasining murakkabligiga qarab birlamchi, ikkilamchi yoki ko'plamcha qavatlardan iborat bo'lishi mumkin. Ularda izlar, tagliklar, via teshiklar va lehim maskasi kabi turli elementlar mavjud bo'lib, barchasi ham to'g'ri ishlashni ta'minlash uchun birgalikda ishlaydi. Bu platlar fotolitografiya, etch qilish va plating kabi murakkab jarayonlar orqali ishlab chiqariladi, bu esa komponentlarning aniq joylashtirilishini va ulanishini ta'minlaydi. Bu platlar oddiy iste'mol elektronikasidan tortib, murakkab sanoat jihozlari, tibbiyot asboblari va kosmik dasturlargacha hamma narsada muhim ahamiyatga ega. Zamonaviy PCB lar tebranish boshqaruvi, issiqlikni boshqarish tizimlari va yuqori tezlikdagi signallarni yo'naltirish imkoniyati kabi ilg'or xususiyatlarni o'z ichiga oladi, shu tufayli ular yanada murakkab elektron tizimlarni qo'llab-quvvatlashga qodir.